Theme

Digital Transformation

Green Transformation

HUNG CHIH LIMITED COMPANY

Product Description :

Grundfos offers a wide range of pump products, including circulator pumps, submersible pumps, immersion pumps, centrifugal pumps, and dosing pumps. Additionally, Grundfos provides Energy Audits and Energy Optimization services to help businesses identify energy-saving opportunities and optimize pump systems, thereby improving energy efficiency and reducing operational costs. These services and products demonstrate Grundfos’ expertise in pump technology and energy saving capability .

Grundfos is also committed to providing energy-saving solutions that are widely applied in various fields

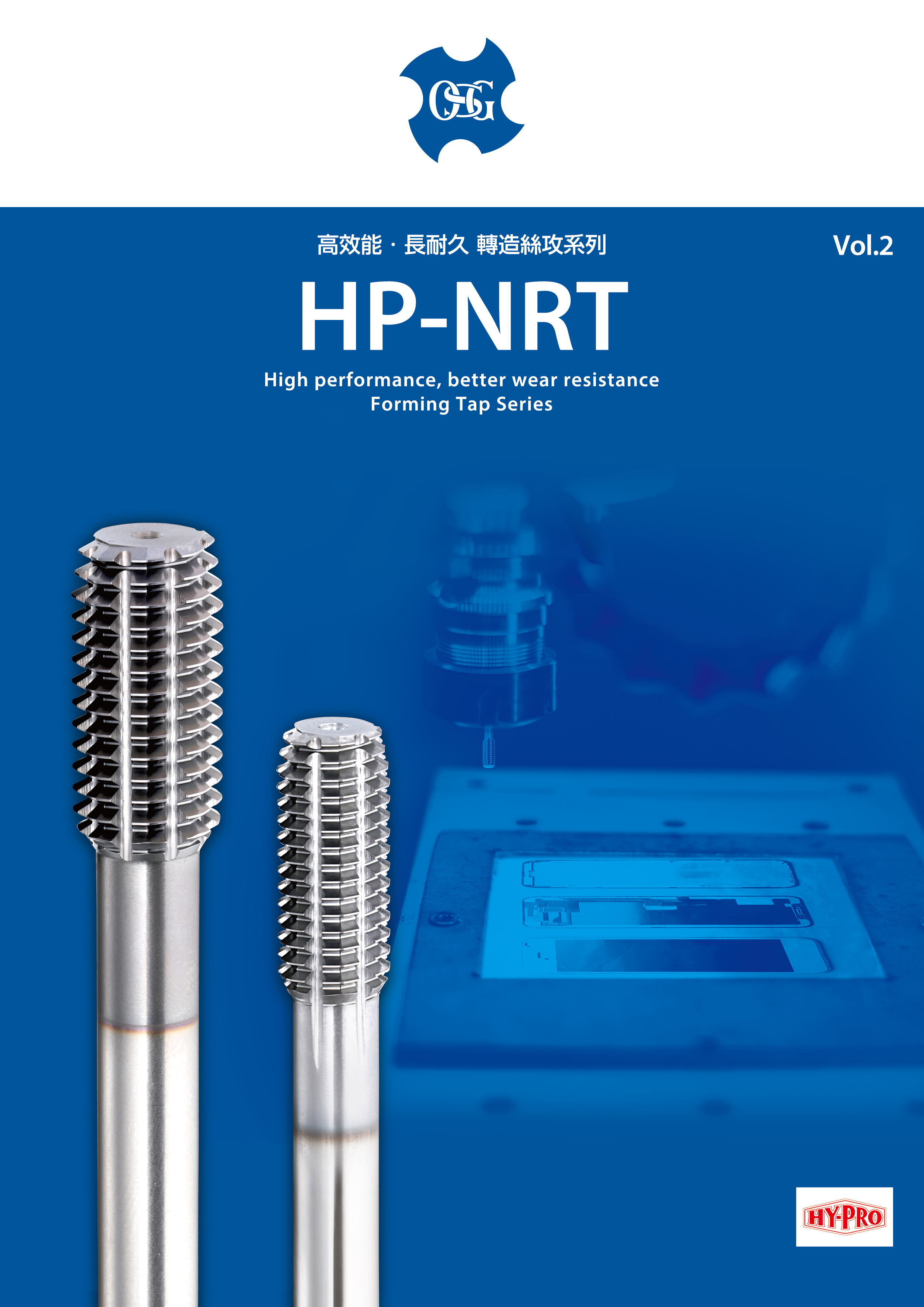

TAIHO TOOL MFG. CO., LTD.

Product Description :

Using powder metallurgy HSS is suitable for high hardness material tapping and stability of the tool life. Special thread design can lower the forming torque and improve the quality of internal thread after tapping. Multi-flutes design can let the cutting oil directly inject into tapping point, which can improve lubricity which effectively control tapping heat and extend tool life. TiCN coating provides welding and wear resistance ,which can lengthen the durability of taps. Special thread design can lower the forming torque and improve the quality of internal thread after tapping. Multi-flutes design can let the cutting oil directly inject into tapping point, which can improve lubricity which effectively control tapping heat and extend the tool life. TiCN coating provides welding and wear resistance, which can lengthen the durability of taps.

HP-NRT series include standard type(HP-NRT), and short chamfer type(HP-SC-NRT).

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

向全球使用金利成刀具的加工航太客戶,深深感謝。

JLC為全球客戶開發了多款加工鈦與WASPALOY及鎳基材料的經典刀款,獲得客戶的持續讚賞與肯定,我們也因為航太客戶的持續互動,一直追求創新與進步。

航空零部件不僅採用了很多新結構、新技術和新材料,零件也越來越講求精密與材料合適性。為了讓客戶在航太的加工上,有更多元的因應方式,我們正式推出新設計的航太特殊材料用刀– AP系列。

整體子彈流動力學的設計理念,與一貫的優質歐系棒材,再搭配更勝一般鈦矽的複合及類鑽鍍層,經過廠內多次的實驗,AP航太系列刀具,絕對讓您面對航太材料加工上游刃有餘。

歡迎全球客戶指教,金利成再次感謝您的支持。

DOWELL CO.,LTD.

Product Description :

ESPRIT® is a high-performance CAM system for CNC programming, optimization and simulation — supporting any class of CNC machine via one common user interface and workflow. Using a digital twin of the CNC to simplify the programming process, ESPRIT delivers edit-free G-code. Combined with ESPRIT's ability to solve workflow challenges with individually tailored automation solutions, ESPRIT is the smart manufacturing solution for any machining application.

With world-class technical support, ESPRIT empowers you to get started quickly and keep your shop running at top efficiency. ESPRIT is the only CAM system you’ll ever need.

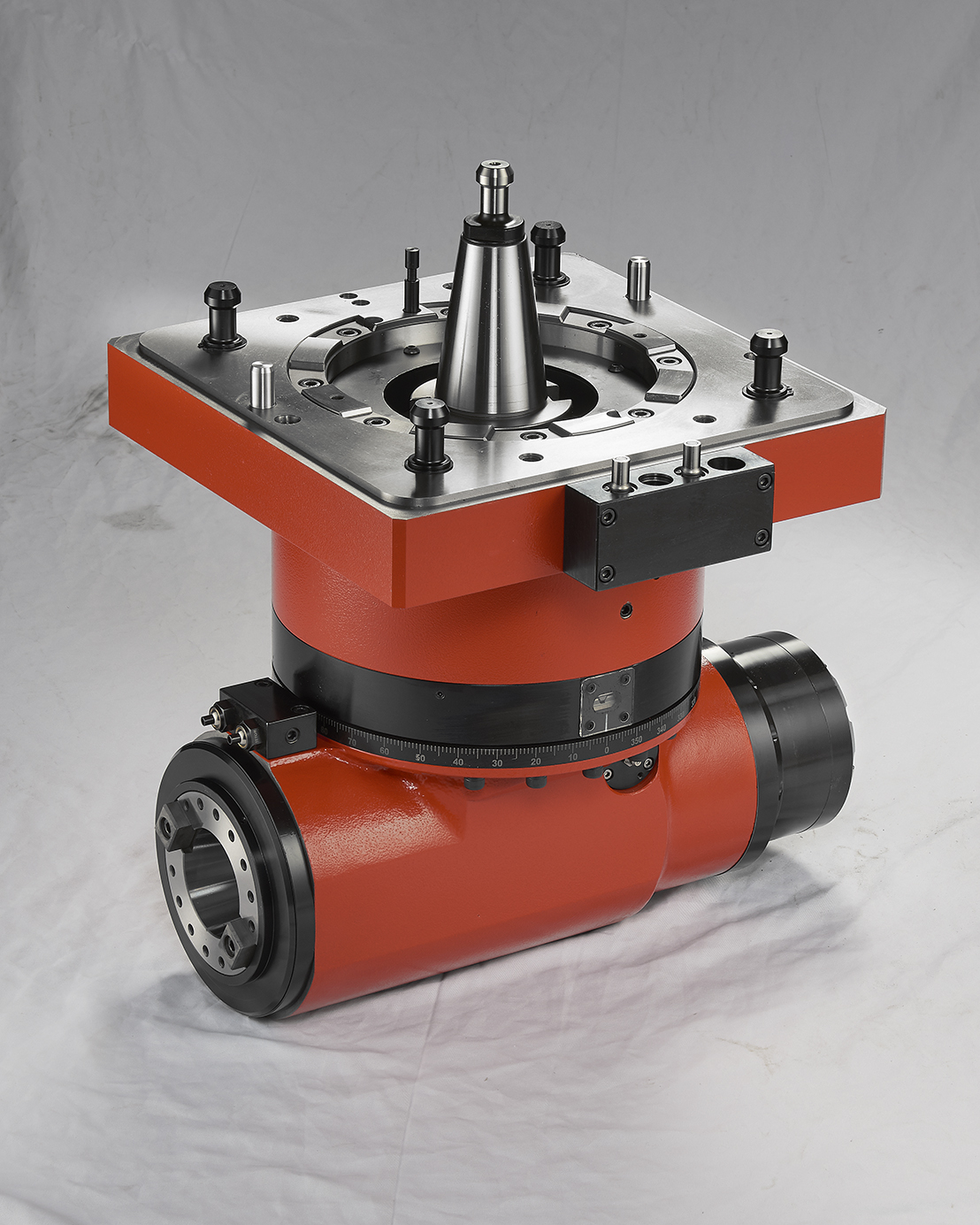

CHANDOX PRECISION INDUSTRIAL CO., LTD.

Product Description :

固定式氣油壓夾治具,適合工作平台的鑽銑加工使用。

1.內藏式氣油壓缸設計,接上動力源即可使用。

2.大直徑中心通孔,提升夾持應用範圍。

3.防塵裝置設計,使立式加工的切屑與雜質不易進入夾頭。

4.可選用氣壓或油壓驅動。

With built-in type cylinder, it is ideal for machining application on working table.

1.Rust-proof for Pneumatic Cylinder : Inside wall of cylinder being rustproof treated; cylinder can work under wet or high moisture circumstances without rusty or seized trouble.

2.Dusts-proof and Waterproof : Dust-proof and Waterproof structure prevents work-chips and coolant water from entering into inside of chuck cylinder to maintain its accuracy and lead to longer service life.

3.Benefit of Built-in Cylinder : The cylinder is connected to chuck itself directly for obtaining better stability, less space, and higher machining efficiency.

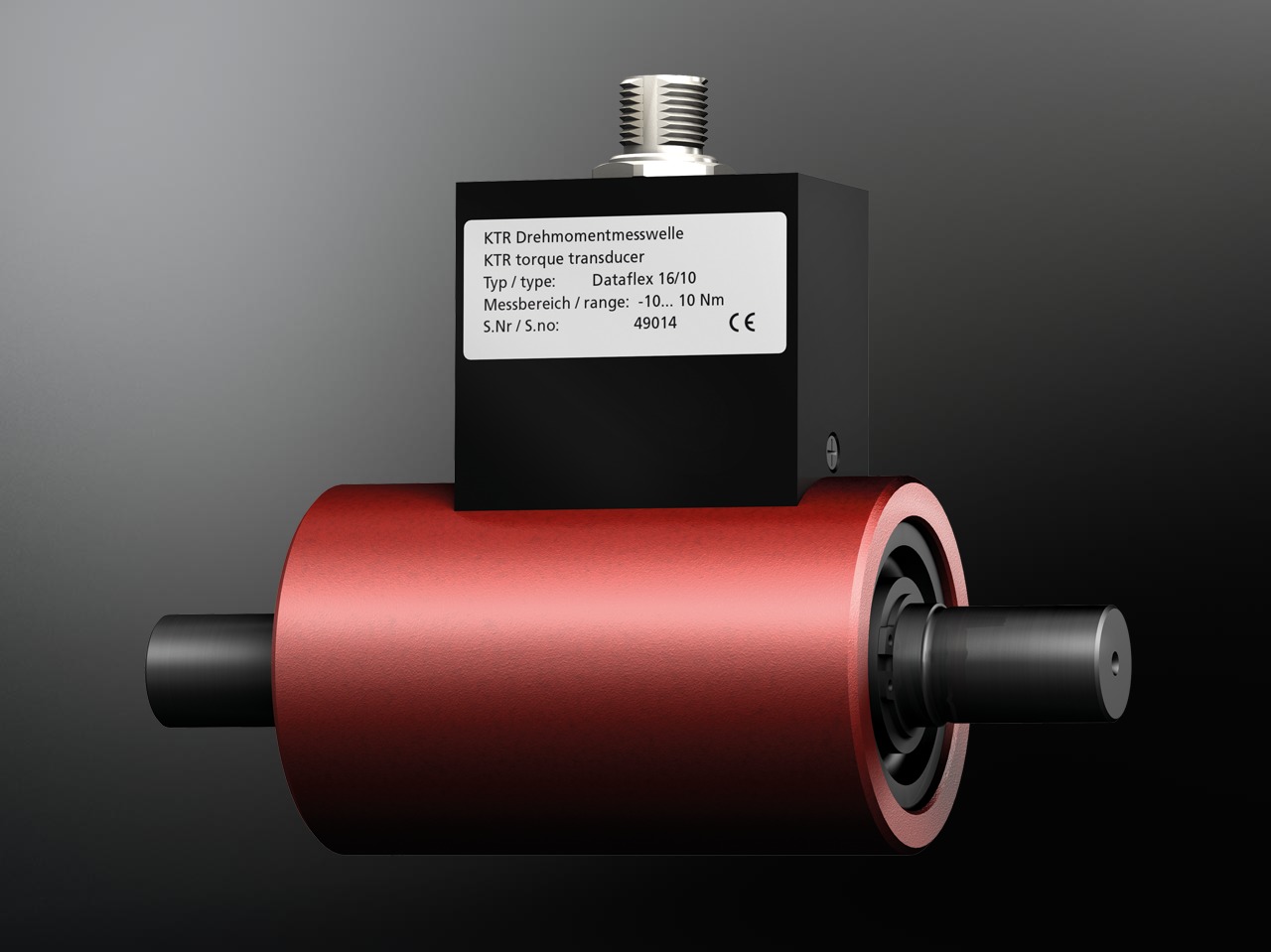

KTR TAIWAN LTD.

Product Description :

The recently developed DATAFLEX® 16 is available for measuring torque ranges of 10 Nm, 30 Nm and 50 Nm. The torque is measured using the well-approved technology of wire strain gauges combined with the latest electronic components.

The torque signals are processed without contact at a high resolution of 24 bit achieving an accuracy of 0.1 % of the terminal value. Supplementary to torque measuring the size 16 has a speed encoder providing two signals with a resolution of 360 pulses per revolution.