Theme

Digital Transformation

Green Transformation

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

Product Description :

The oil return filter is mainly installed on the oil return line of the hydraulic system. Various impurities such as abrasive particles generated during the work of various hydraulic components can be blocked by setting the oil return line to filter and avoid returning to the tank again.

CAPTAIN SCIENCE CORPORATION

Product Description :

GENERAL DESCRIPTION RTB bearings (standabearings consist of a L-shaped inner ring - complet-ed with a washer -, an outer ring, two roller thrust bear-ings and a cylindrical roller bearing, full complement.Unitec has modified the inner design of RTB bearings and therefore load-carrying capacity and stiffness values may differ from the ones of past designs indicated on previous catalogues. The axial and radial load ratings have been calculated according to UNI ISO 76 and UNI ISO 281 standards.

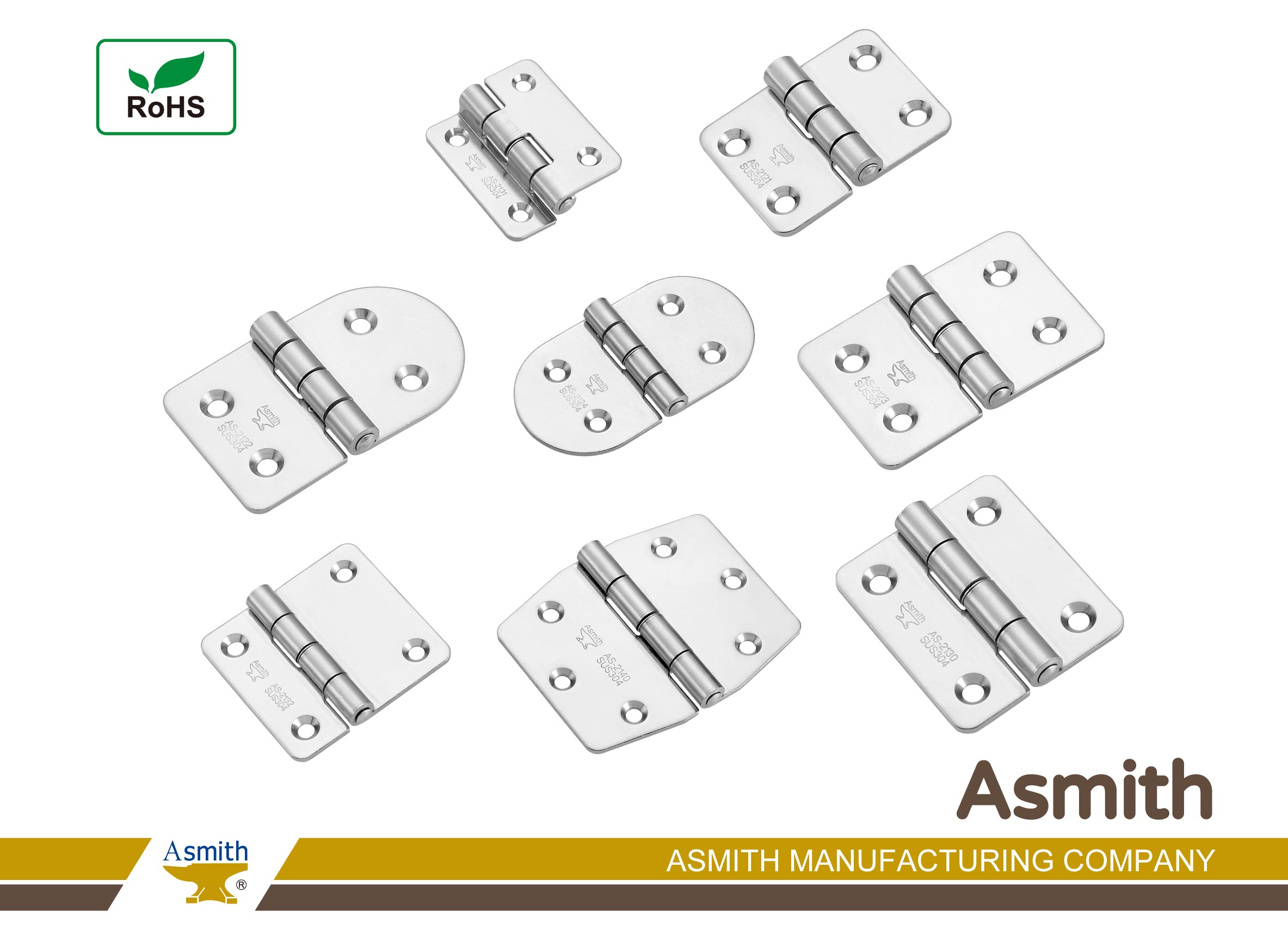

ASMITH MANUFACTURING COMPANY

Product Description :

AS-21 Series

Micro-damping friction butt hinge allows the door panel to be fixed at any position when opened left or right. Features stepless self-positioning control. Counterbore hole design, suitable for countersunk screws.

More info:https://www.asmith.com.tw/en/products/Hinge/Butt/AS-21

DOWELL CO.,LTD.

Product Description :

ESPRIT® is a high-performance CAM system for CNC programming, optimization and simulation — supporting any class of CNC machine via one common user interface and workflow. Using a digital twin of the CNC to simplify the programming process, ESPRIT delivers edit-free G-code. Combined with ESPRIT's ability to solve workflow challenges with individually tailored automation solutions, ESPRIT is the smart manufacturing solution for any machining application.

With world-class technical support, ESPRIT empowers you to get started quickly and keep your shop running at top efficiency. ESPRIT is the only CAM system you’ll ever need.

Chen Ying Oil Machine Co., Ltd.

Product Description :

1.The operation and interval time of KGA and KGAP are controlled by PLC.

2.A magnetic level switch can be added to KGA and KGAP on request to detect the grease level automatically.

3.Please refill grease from the grease inlet of KGA and KGAP to prevent air and impurities from entering the grease tank.

4.KGAP has a metal spring inside its grease tank, enabling it to work with thicker grease viscosity NLGI 1 and NLGI 2, while KGA is only available for NLGI 000 to 0.

RAISE PRECISION CO., LTD.

Product Description :

Capacitive switches with touch sensor technology

The first capacitive switches with touch sensor technology from CAPTRON were used in 1994 for public transportation. Today, CAPTRON offers a wide range of capacitive SENSORswitches for various industries and applications where unconditional reliability, durability, comfort and design are required.

If necessary, SENSORswitches from the standard range can be tailored and modified optically and technically to meet individual customer demands.