Theme

Digital Transformation

Green Transformation

JAR HON MACHINERY CO., LTD.

Product Description :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic tapping process. One operator can easily operate several machines at the same time.

3.By using proper master pitch gears(change gears A and B pair), highly accurate thread can be tapped. It is easy and quick to change different size.

4.The length of the tapping stroke can easily be adjusted for high accuracy which is suitable for tapping blind hole parts.

5.It has safe device to monitor the feeding, torque, radial, and clamping to keep TAP's long life and ensure safe working job.

6.It governed by PLC.

7.Long parts or those can't feed in vertical position are suitable.

8.Pre-work parts auto-checking and machine auto-stop if abnormal.

GP MACHINERY CO., LTD.

Product Description :

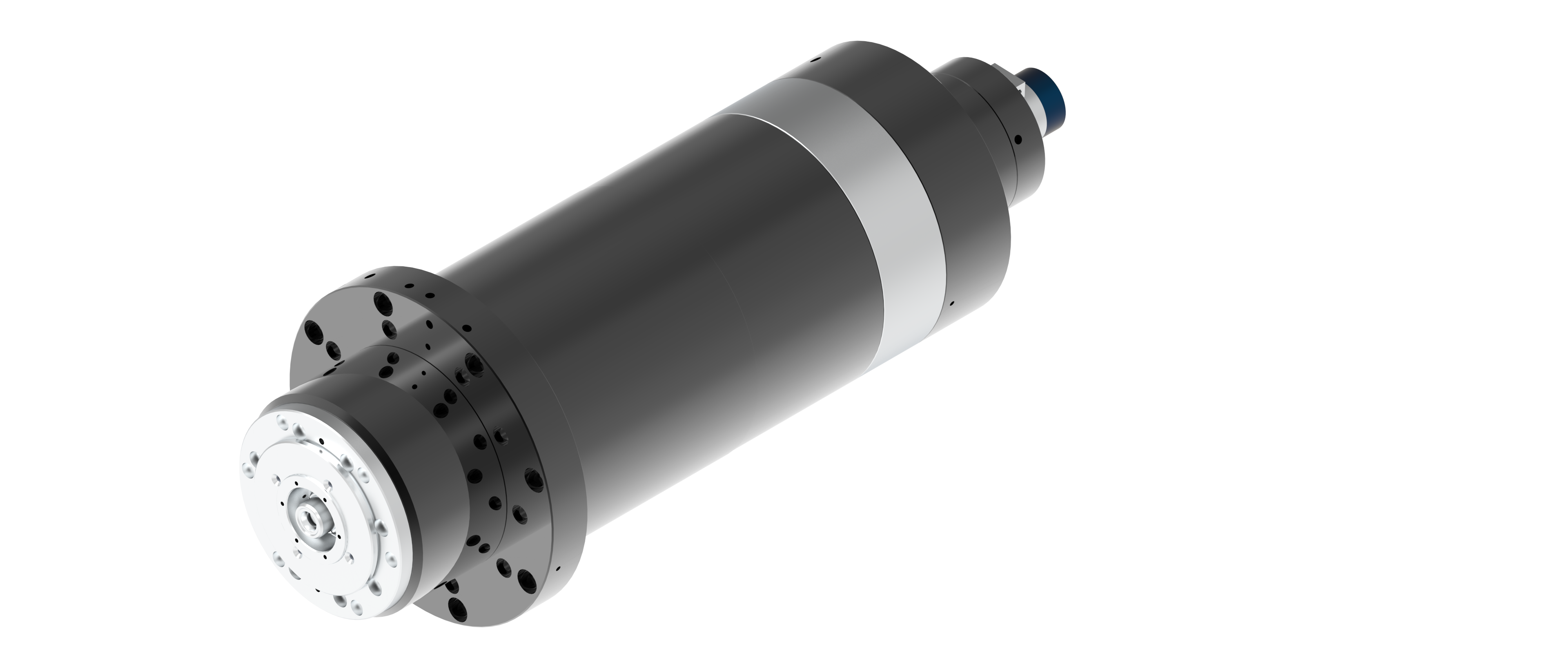

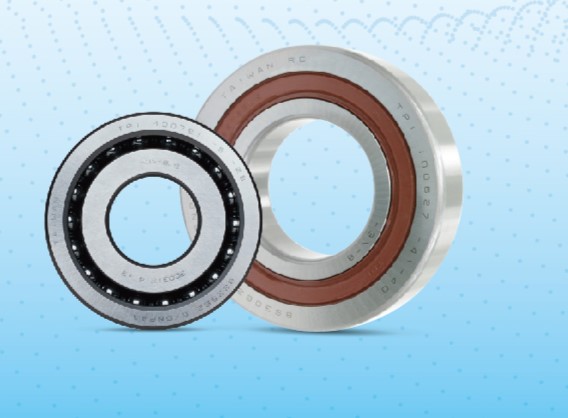

Built-In Spindle

◆ Lightweight design.

◆ After the mandrel is cryogenically treated, the heat variable is small and the machining accuracy is excellent.

◆ The internal cooling system adopts spiral circulation to achieve high-efficiency operation.

◆ The spindle adopts ceramic ball bearings from Europe to achieve optimal power and excellent rigidity.

◆ With standard accessories bearing temperature sensor PT-100.

RAISE PRECISION CO., LTD.

Product Description :

Our range of optical sensors comprises classic forked light barriers with red light or infrared technology. Still greater accuracy is offered by our laser light barriers, which even respond to tiny objects.

The special design with integrated air system is an optimal solution when it comes to contamination, as the air system prevents dust and dirt from collecting on the transmitter and receiver.

A further CAPTRON innovation is the product series of TCP measurement units with laser. TCP measurement units ensure a highly precise tool calibration and precise XYZ measurement in industrial robots. TCP measurement units are commonly used in robot-based automation processes in the metering and bonding technology, welding, soldering and in the food industry.

TAIWAN RONG FU INDUSTRIAL CO., LTD.

Product Description :

8” X 12” Step Pulley

Allows 0-45º Angle Cutting

Cast Saw Bow, Work Table, & Blade Wheels for Rigidity & Strength

Fully Adjustable Hydraulic Downfeed Control

Full Enclosure Metal Blade Cover for Safety

Bearing Blade Guide for improved Stability

Extended Blade Life

Reduced Consumables Cost

4 Speed Step Pulley for Different Cutting Speeds

Quick Moving Vise for Easy & Fast Clamping

Handy Pulley Cover, Convenient for Belt Step Changing

HAI JU TRADING CO., LTD.

Product Description :

High-strength connection and maximum sealing

Can you imagine high-quality products without screw connections?

Modern technology cannot do without them as detachable joints. In the industrial

sector, fluid technology, pneumatics and sealing technology are among the fields of

application. In those sectors, often additional functions such as sealing, insulation or

reuse of bolts are required – only to mention a few.

One classic example are adjusting screws on hydraulic components, steering boxes

and fuel injection pumps. For those applications, high-strength screw connections

with reusable bolts and sealing against leakage are essential. We provide the solution

that fulfils those high requirements: the SEAL LOCK® sealing nut. It prevents any

unwanted leaking of gaseous or liquid media. The SEAL LOCK® ring integrated on

the nut helps to achieve reliable sealing inside the thread without the use of

additional elements. It is reliable in two ways because it seals under the head and

inside the thread. Not to mention the easy installation.

The following figures show conventional solutions on the one hand and the

SEAL LOCK® sealing nut on the other hand.