Theme

Digital Transformation

Green Transformation

Sterling TSI Co., Ltd.

Product Description :

Measurements Include:

1. Straightness

2. Flatness

3. Parallelism

4. Perpendicularity

JINN FA MACHINE INDUSTRIAL CO., LTD.

Product Description :

Max. turning diameter 20mm.<br />

JSL-20RB:C1/Z1/X1/Y1/C2/Z2/X2.<br />

JSL-20RBY:C1/Z1/X1/Y1/C2/Z2/X2/Y2.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

■Choose Machine : Tsugami S205/S206■Detailed specifications

▼Speed ratio :1:1▼Maximum speed : 5000RPM▼

▼Tool clamping : Utilis no.119287▼Angle adjustment : ±20°

▼Reference code : 3281-Y450

https://www.songgia.com.tw/en/products/thread-whirling-unit-tssa545201

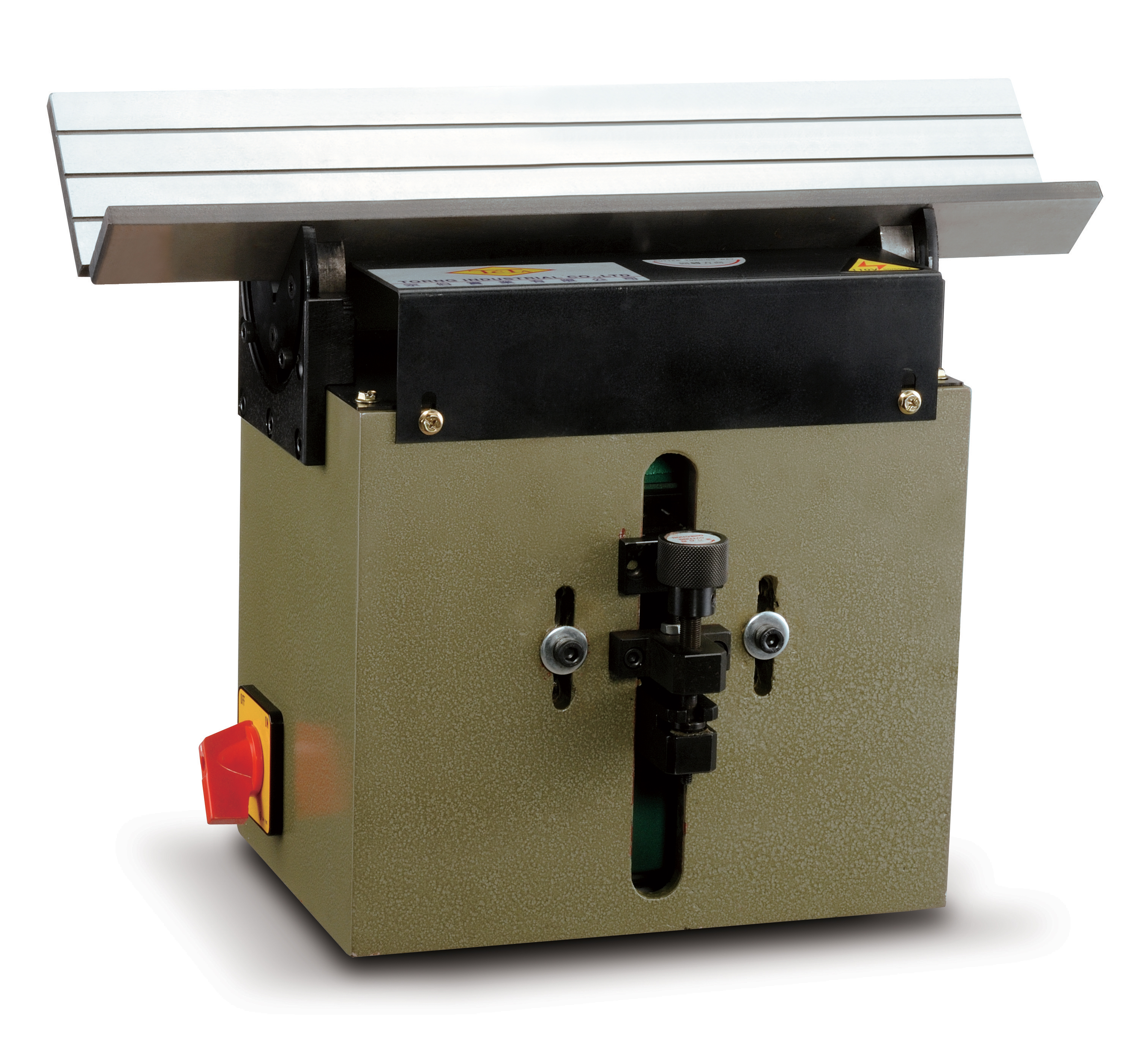

TORNG INDUSTRIAL CO., LTD.

Product Description :

* It adopts the principle of face milling, the chamfering method is like milling.

* Suitable for carbon steel,alloy steel,iron and aluminum.

* After chamfering, its surface is smoother than side cutter.

* Bevel angle : 45 degree.

* Angle can be adjusted.

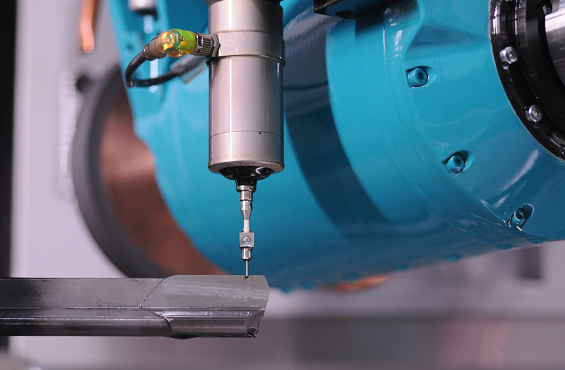

YING HAN TECHNOLOGY CO., LTD.

Product Description :

YTL8320G

CNC computer lathe and portal robot arm

Machine features

- Automated process control

- Mass production of extremely precise workpieces

- Visual programming made easy

- Efficient process intelligence

Machine specifications

- 8-inch spindle chuck

- 45 degree slant back bed

- Z/X axis travel: 320/185mm

- Max. load of robotic arm is 4kg

- 10 station of storage capacity

Protool Industrial Corp.

Product Description :

Drilling length can achieve up to D x 250.

Excellent hole straightness and concentricity.

Excellent surface quality.

Easy regrinding.

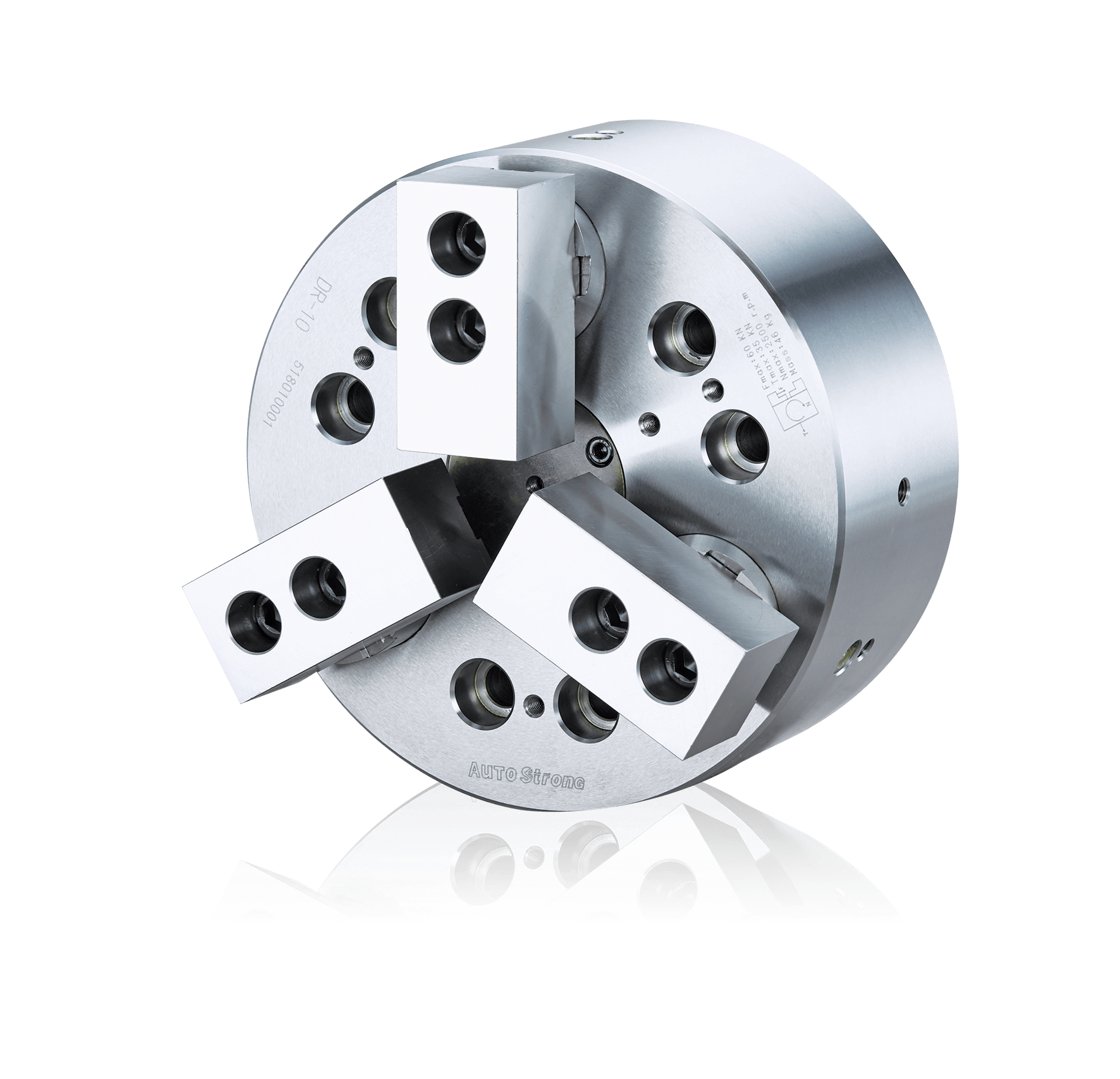

CHANDOX PRECISION INDUSTRIAL CO., LTD.

Product Description :

固定式氣油壓夾治具,適合工作平台的鑽銑加工使用。

1.內藏式氣油壓缸設計,接上動力源即可使用。

2.大直徑中心通孔,提升夾持應用範圍。

3.防塵裝置設計,使立式加工的切屑與雜質不易進入夾頭。

4.可選用氣壓或油壓驅動。

With built-in type cylinder, it is ideal for machining application on working table.

1.Rust-proof for Pneumatic Cylinder : Inside wall of cylinder being rustproof treated; cylinder can work under wet or high moisture circumstances without rusty or seized trouble.

2.Dusts-proof and Waterproof : Dust-proof and Waterproof structure prevents work-chips and coolant water from entering into inside of chuck cylinder to maintain its accuracy and lead to longer service life.

3.Benefit of Built-in Cylinder : The cylinder is connected to chuck itself directly for obtaining better stability, less space, and higher machining efficiency.

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 2600 x 650 mm

Longitudinal travel: 2400 mm

Cross travel: 800 mm

Y slide way width: 1980 mm

Z Slide high: MAX 800 mm

Z Slide way width: 500 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 4P

Spindle speed: 70~1200 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø40 mm P=8 C3

Net weight: 6800 kgs

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

DI CHUN IRON WORK CO., LTD.

Product Description :

Drawdown power chuck feature of radial clamping will lead to almost no workpiece uplifting displacement; for machining casting and forging part:

1. For the clamped workpiece is oppressed to the surface, chucks are suitable for heavy machining.

2. Chuck Actuators with the cylindrical structure is durable and ensures high clamping repeatability.

3. Accurate self-centering and pull back features are adequate or precise length control machining requirements.