Theme

Digital Transformation

Green Transformation

WEXTEN PRECISE INDUSTRIES CO., LTD.

Product Description :

■ The unit is lightweight, easy to install and noiseless.

■ Unlike traditional air conditioners, the system utilizes oil/water for heat exchange, instead of piping refrigerant gas directly to the cooling coils.

■ Amazing performance even in high environmental temperatures.

■ Achieving energy savings and carbon reduction by applying secondary circulation with P.C.W. or the oil/water coolers.

■ No compressor, no need for refrigerants, so no concerns about Global Warming Potential (GWP) values.

WIN-HIGH CO., LTD.

Product Description :

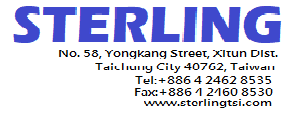

牌號: 適用加工材料:<br />

<br />

MD10 厚度小於0.2毫米的銅、鋁等薄片<br />

<br />

MD15 銅、鋁、不銹鋼等薄片<br />

<br />

MD20 通用性強,銅、鋁等薄片<br />

<br />

MD35A Q195 、SPCC等冷軋板<br />

<br />

MD36 EI 片、SPCC板等<br />

<br />

MD40A Q195 、SPCC等冷軋板<br />

<br />

MD45A 矽鋼片,冷軋板<br />

<br />

MD55 矽鋼片,上下沖頭<br />

<br />

ST05B 耐磨性好,模腔形狀簡單的模具。<br />

<br />

ST15B 通用性強,軟磁材料,鐵、銅基粉末模具。<br />

.<br />

ST10F 超細晶粒,適合硬磁材料成形模具。<br />

<br />

MD45A 適合型腔複雜的模具。<br />

<br />

MD50A 適合高負荷且型腔很複雜的模具。<br />

<br />

ST10B 綜合性能好,加工實木、密度板、刨花板及灰口鑄鐵、有色金屬等材料。<br />

<br />

ST10C 通用性強,加工實木、密度板、灰口鑄鐵、有色金屬等材料。<br />

<br />

ST03F 超細晶粒,抗腐蝕性能好、高耐磨,適用於有腐蝕介質的竹木刀具及製動材料的切削刀具。<br />

<br />

ST05F 超細晶粒,高硬度、高耐磨,適用於竹木刀具。<br />

<br />

ST10F 超細晶粒,適合製作形狀簡單的木工刀具和加工銅鋁合金、PCB、玻纖強化材料、制動材料、 <br />

石墨。<br />

<br />

ST11F 超細晶粒,適合加工硬木、密度板、刨花板等木工,竹木材料及加工鋁合金、淬硬鋼、冷硬鑄 <br />

鐵、制動材料。<br />

<br />

ST12F 超超細晶粒,適合加工刨花板, 不銹鋼、高淬硬鋼(硬度>HRC60)、玻纖強化材料,尤其適 <br />

合金屬的高速切削和乾切削。<br />

<br />

ST15F 超細晶粒,適合加工硬木、密度板、刨花板等木工材料及纖維強化材料。<br />

<br />

ST20F 通用性強,主要適用於灰口鑄鐵、冷硬鑄鐵、合金鋼等。<br />

<br />

ST25F 高溫合金、不銹鋼、鈦合金、淬硬鋼、絲錐。<br />

<br />

MD46A 耐磨性要求高,縮徑、單次變形量小的模具。<br />

<br />

MD50A 加工不銹鋼以及單次變形量不大的模具。<br />

<br />

MD60A 直桿,螺絲,螺帽上模等。<br />

<br />

MD62A 工作負荷較大的沉頭模具。<br />

<br />

MD65A 工作負荷較大的直桿模具。<br />

<br />

MD70A 螺帽下模、工作負荷大的模具<br />

ST06F 直徑小於1.5mm的鋼絲、鎢絲、鉬絲等硬材高速拉絲拉拔和表面光潔度要求很高的有色金屬線 <br />

材的拉製。耐腐蝕性強,在酸性潤滑拉伸時更為優越。<br />

<br />

ST19F 直徑在1.5mm~15mm範圍內的鋼絲、鎢絲、鉬絲等硬材高速拉絲拉拔和表面光潔度要求高的 <br />

有色金屬管(線)材的拉製。<br />

<br />

ST10UF 700系鋁、PCB、銅鋁合<br />

<br />

ST25EF 不銹鋼、模具鋼、高溫合金

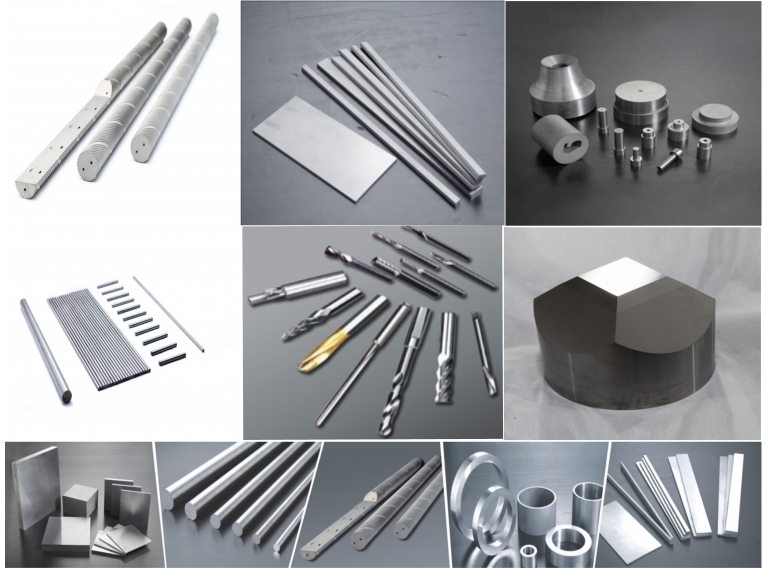

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

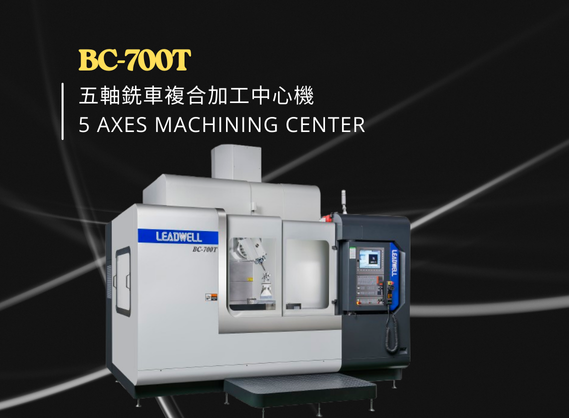

KUNJUNG CORPORATION

Product Description :

•零背隙設計使“作動”更加卓越

>RollerDrive 為近幾年因應工具機械製造公司所要求的更迅速(高速)更精確(高精準)功能而設計的CNC工作台。CNC工作台搭載本公司的零背隙減速機構「RollerDrive」,在使用上有別於齒輪或是轉矩馬達,能夠不受外力影響並維持穩定的動作。不僅可實現回轉角度精度10秒以下的高精度定位,同時在硬鋼的重切削作業上也能夠完美對應。除此之外,RollerDrive CNC工作台即使經過長時間使用,也不會造成產品內部元件損耗,精度下降等情形池因為具備卓越的耐久性,不需要對設備做定期的校正及調整作業。

•RollerDrive 作動原理

>RollerDrive 透過採用優良運動控制元件之-的滾子凸輪,入力軸(滾子凸輪)呈螺旋的形狀並與滾珠在預壓的狀態下接觸,使之達到完全的零背隙。 以獨特的調整機構零件,將預壓調整至最適合的狀態。配置於出力軸的滾珠,內部的滾珠軸承構造,能夠在運作轉動的同時傳遞扭矩。

詳細請參閱官網說明:https://www.kun-jung.com/sankyo-rotary-table.html

CHEN SHIN (TCSM) MC CO., LTD.

Product Description :

Oil mist collector:

Totally made in Taiwan with TÜV CE marking.

Customisation Accessories ,Industry 4.0 Accessories and ODM/OEM Services are available.

Welcome for ODM/OEM cooperation.

We are Agent of SCOTTI in Taiwan market.

We are Agent of DUPLOMATIC in Taiwan market.

Electrical Oil Mist Collector