Theme

Digital Transformation

Green Transformation

CIN EY DIAMOND WHEEL COMPANY

Product Description :

The TDCS grinding wheel from TEIKEN Japan uses diamond and resin abrasives, suitable for grinding various materials such as cemented carbide and SKD (stainless steel), and is also suitable for hard workpieces such as ceramics. Using high-toughness, blocky, high-grade diamonds, this wheel can grind difficult-to-machine materials more efficiently without losing sharpness.

It allows for longer dressing intervals and less wheel wear. It is available in various models, including the porous BK wheel and the Synergy wheel with a ceramic body. It is particularly suitable for simultaneously grinding high-strength steels, such as tungsten carbide and SKD, for use in the manufacture of motor core molds.

YIH KUAN ENT CO., LTD.

Product Description :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.

WELE MECHATRONIC CO., LTD.

Product Description :

1.立車主軸轉盤以進口交叉滾子軸承設計,確保重負荷的能力及長期的精度壽命。

2. Z軸226 mm方型滑枕搪孔軸採硬軌配Turcite B結構,VTC1612-CW標準行程900mm。

3.底座、立柱、橫樑、工作台等大型鑄件依製造需要,經由最新的3D設計,剛性最佳化,並以

多年經驗訂定有效的退火程序以消除殘餘應力,多年實際應用經驗,確實能達成有效的長期精

度保持性。

4.X、Z軸標準配備採用「雙編碼器」的「雙」半閉環回饋系統,經濟有效的提高各軸的定位精度。

(X、Z軸可選購德國Heidenhain或西班牙FAGOR光學尺)。

5.VTC-CW標準刀庫容量為16P(16儲位),車刀型式及分配數目可依客戶要求處理。

6.主軸箱等關鍵零件係利用自有的「大型臥式鏜孔機」及「大型高精度三次元量測儀(三座標量床)」

確實達成應有的加工精度,確保優良的組裝基礎。

7.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密

精度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的

幾何精度,確保機器應有的精度和壽命。

8.搭配高規格的Fanuc數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、

2MB記憶容量、Ethernet網路接口、Flash記憶卡插口、剛性攻牙及各種特殊補間(插補)等多項

高規格功能,能經濟有效的滿足各種使用需求。

9.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

10.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等

精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

11.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

12.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。

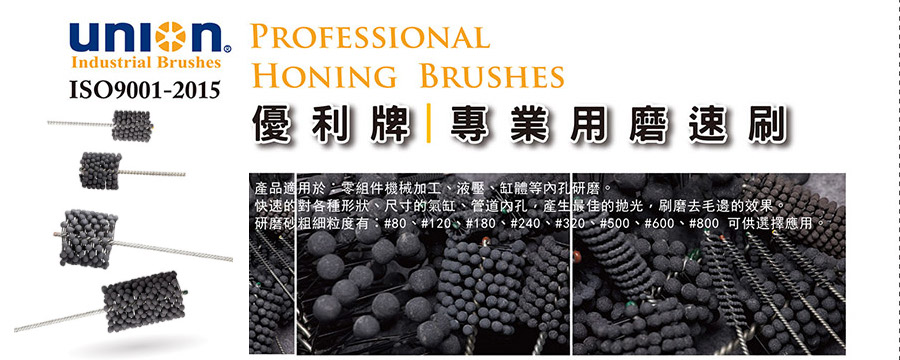

EANG LIAN CORPORATION

Product Description :

UNION Professional Honing Brushes Applications: Brake Cylinders, Hydraulics, Valve Guides Abrasive Type/Grit Size : #80、#120、#180、#240、#320、#500、#600、#800 Strong twisted wire handle for Hand or Drill use. Sizes to suit bores from 6.3 to 203mm. Ideal for surface finishing, blending and burr removal. Always use good quality honing fluid and start honing at low speed.</p>

PHB Flexible Honing BrushesF/lexible Honing Brushes

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

Angle encoders for rotary and tilting axes are indispensable for machine tools on which high positioning accuracy and a high machining rate are essential. Because angle encoder measure angular motion of the axis directly and immediately. Mechanical transfer elements therefore have no influence on position measurement, both kinematics errors and the influences of forces are measured by the angle encoder and considered in the position control loop. This can eliminate a number of potential error sources: Gear errors, reversal error, errors due to deformation of the drive mechanics by machining forces.

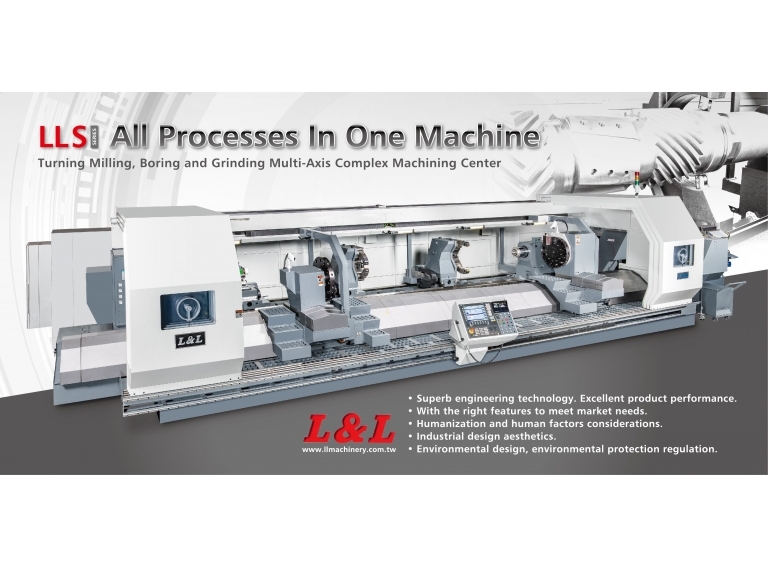

L & L MACHINERY INDUSTRY CO., LTD.

Product Description :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.

YING HAN TECHNOLOGY CO., LTD.

Product Description :

YTL8320G

CNC computer lathe and portal robot arm

Machine features

- Automated process control

- Mass production of extremely precise workpieces

- Visual programming made easy

- Efficient process intelligence

Machine specifications

- 8-inch spindle chuck

- 45 degree slant back bed

- Z/X axis travel: 320/185mm

- Max. load of robotic arm is 4kg

- 10 station of storage capacity

進桜電機株式会社

Product Description :

We are a manufacturer of induction motors.

With advanced high-speed and high-precision design and manufacturing technologies, we provide integrated production services—from design to final manufacturing—tailored to customer requirements. Our products serve a wide range of applications, including specialized processing machinery, woodworking equipment, metal and resin processing machines, FPD (Flat Panel Display) equipment, as well as ultra-specialized motors for pharmaceutical, chemical, and aerospace industries.

Since we manufacture the stator coils—the core component of the motor—in-house, we are able to design and produce custom spindle motors according to each customer’s specific needs.

CAPTAIN SCIENCE CORPORATION

Product Description :

Established in 1935 as a subsidiary of The Felters Company, originally working primarily in the shock/vibration field, UNISORB® has grown to be the leader in providing a full spectrum of advanced products and innovative engineering for the installation of a wide variety of capital equipment used in General Manufacturing, Metalworking, Testing and Verification, Printing, Power Generation, and a wide variety of other areas.