Theme

Digital Transformation

Green Transformation

Alpha Precision Instrumentation Corp.

Product Description :

The FaroArm is a portable coordinate measuring machine (CMM) that allows manufacturers easy verification of product quality by performing 3D inspections, tool certifications, CAD comparison, dimensional analysis, reverse engineering, and more.

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Product Description :

Expertise, Innovation, Performance

S5A-4732HH, Special for Difficult-to-Cut Materials processing, Titanium Alloy processing.

Features:

High-Rigidity structure design. Mechanical-type Simultaneous Two-Axis rotary spindle. Warm and gear transmission for B and C axes. With self-made heavy-cutting two-stage gearbox design (Gear Ratio by 1:1.75 and 1:7). Maximum Torque: 1155 N-m.

Unique patented design of the Z-axis spindle rail structure - vibration restrain in machining. It can largely reduce the vibration in machining hard-to-cut material, enhance the machining efficiency, reduce the surface roughness, and prolong the tool’s life. (Model S5A-HH exclusive)

Fully Splash Guarding design. Super large and wide working door design. Fashionable aesthetic and ergonomic safety design.

Specific design of safety guardrail upon the cross column. Convenient for machine maintenance.

Height-adjustable manipulation control box. Suitable for people of different height.

TAIWAN RONG FU INDUSTRIAL CO., LTD.

Product Description :

V:Variable Speed

2F:Spindle Power Down Feed 0.12- 0.18 – 025mm/rev

Gearhead Drill Press with Cross-Slide Table

Rapid Spindle Changes by Quick Select Gear Shift Levers

High Speed Spindle / Quill

Fine Feed Hand wheel for Wide Range Control

Tilting Head Left 90° Right 30°

Suitable for milling and faster drilling setup

LV INTERNATIONAL CO., LTD.

Product Description :

4刃立銑刀(不等分割&不等螺旋)<br />

<br />

1. 藉由刀刃不等分割的設計來減少加工時帶來的振動。<br />

2. 通過改變每個切削刃的螺旋角度可以有效地抑制產生的振動。<br />

3. 高品質的S-FIRE 塗層特別適合用於濕式切削,薄膜表面光滑的特性可減少加工毛邊。<br />

4. 採用優質硬質合金棒材,具有優良的耐磨性和抗張力。<br />

5. 側銑加工時給予絕佳切削能力,並改善工件表面精度。<br />

<br />

適用材料: 合金鋼、工具鋼、不鏽鋼、鑄鐵<br />

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

PCD DIAMOND CUTTING TOOLS:

★ For high-efficiency machining of silicon carbide(SiC), aluminum oxide(Al2O3), zirconium oxide(ZrO2), quartz(SiO2), Silicon(Si) and carbide.

★ Multi-flute design of end mills reduces cutting resistance and enhances machining efficiency.

★ PCD helix tools can effectively shorten machining time, ensure stable machining accuracy and significantly improve production efficiency.

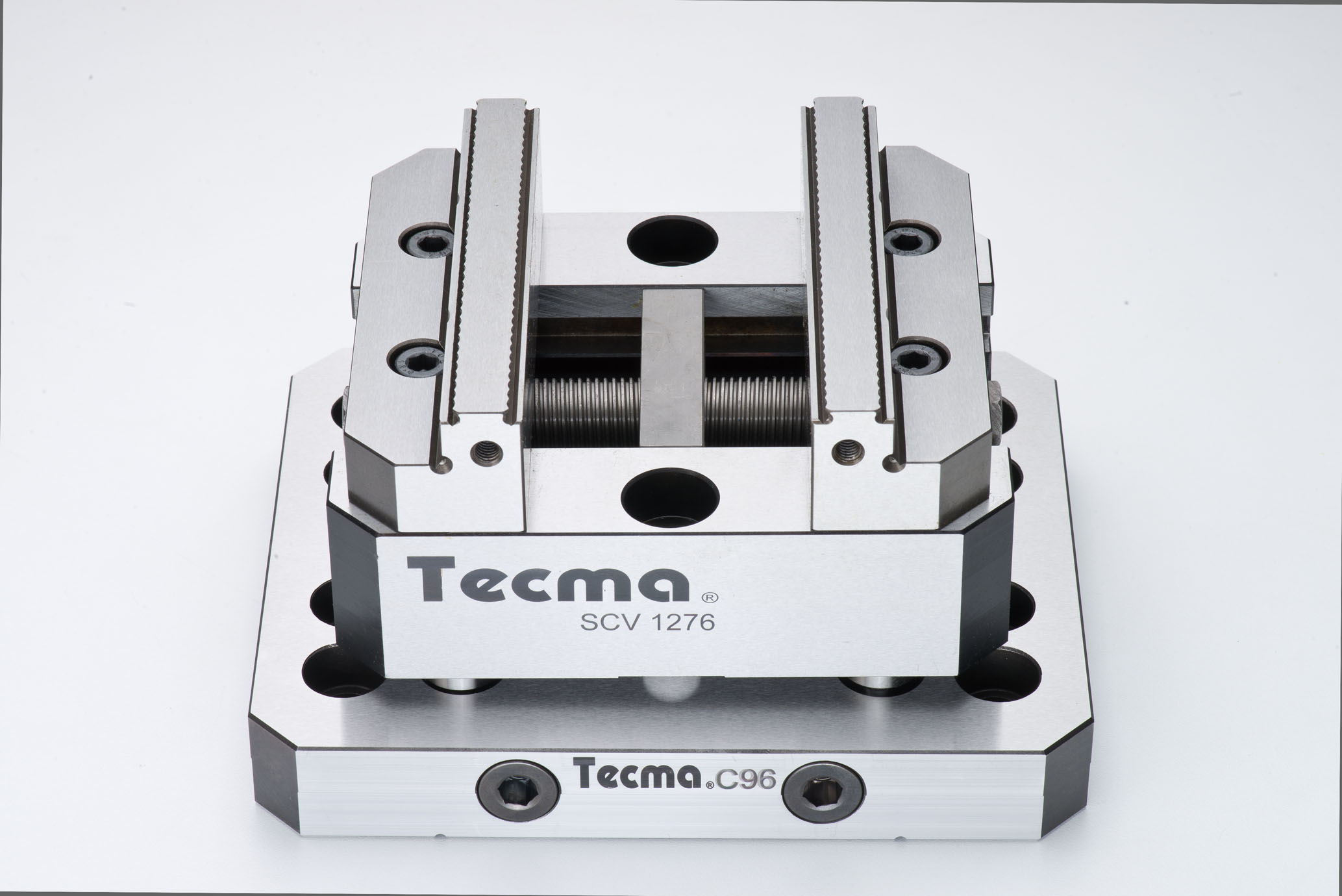

AUTO SUPER CO., LTD.

Product Description :

1. Self Centring Precision Vise is suitable for 4 and 5 Axis CNC Rotary Table usage, either in horizontal or vertical machining.

2. Vise precision of its center repetition position is ±0.01mm.

3. Using high quality alloy steel. Slideway has high frequence heat treatment at HRC 45 or more to keep the accuracy and its long use life.

4. Vise hard jaw material is full Steel and heat treatment at HRC 55~ or more. Owing to its good design to use both sides of jaw since it is exchangeable.