Theme

Digital Transformation

Green Transformation

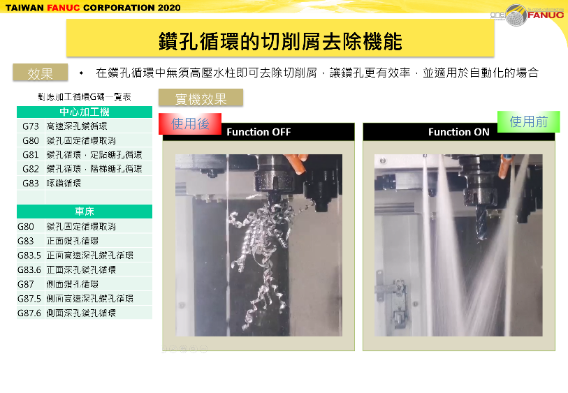

TAIWAN FANUC CORPORATION

Product Description :

Machine center chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.

HIWIN TECHNOLOGIES CORPORATION

Product Description :

DATORKER® Strain Wave Gear (DT)

DATORKER, harmonic gearing system, has the characteristics of high precision, high efficiency, high torsional rigidity, and low starting torque. It is widely used in robots, automation equipment, semiconductor equipment, machine tools and other industries.

HIWIN has developed various specifications to provide customers with wide ranges of choice and be able to provide customized services to meet customer’s various design and technical requirements.

SIEMENS LTD., TAICHUNG BRANCH OFFICE

Product Description :

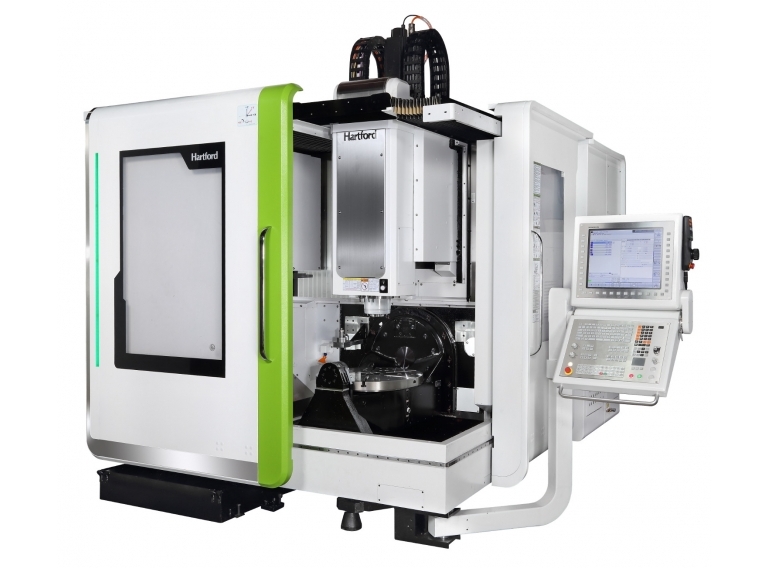

The powerhouse in the compact CNC class

With its unique CNC performance, our SINUMERIK 828D control sets productivity benchmarks when it comes to milling and turning on standard machines as well as functions to simply automate grinding machines. With new SINAMICS drives and SIMOTICS motion control motors SINUMERIK 828D is now even more productive.

SCN MACHINERY CO., LTD

Product Description :

180°油壓反轉合模機 - SDP series<br />

<br />

Tonnage: 50 - 600 ton<br />

Bolster Area: 1000 x 800 - 4500 x 3000 mm<br />

<br />

龍門型高強性、高精度機身設計,操作簡單的控制系統。<br />

動作精確,機台易操作,可減少勞動者的勞累,提高工作安全。<br />

適用於各類精密成型模具精修。(沖壓模、射出模、鋁壓鑄模)<br />

上模可180°完全翻轉,方便工作人員精修模具。<br />

標準附件:10"LCD觸控螢幕。<br />

符合ISO 9001:2015認證