Theme

Digital Transformation

Green Transformation

FOCUS CNC CO., LTD.

Product Description :

30-degree slant bed provides high-stiffness capacity, long-term stability and excellent chip removal capability. Compact design makes the machine length shorter and the floor space smaller. To efficiently utilize the floor space, the chips can be discharged from the side or rear of the machine. To clean the coolant tank from the front of machine to make the plant layout easier. Auto load/unload system provides graphic user interface, quick setup for different work-piece, customized program and work-piece counter. Efficient loading/unloading and quick work-piece swap makes better performance.

TOP POWER MACHINERY ENTERPRISE CO.

Product Description :

The latest crumb collection and +1um precision filtration machine. This bottom debris recovery filter is equipped with a 1.5-inch large suction pump, which can quickly collect and dry the bottom debris and sediment in the water tank, allowing customers to clean it conveniently. This machine is equipped with a multi-functional stainless steel filter barrel that can collect coarse bottom debris. At the same time, using our patented technology, there is no need to replace the filter barrel, and it can continuously perform precision filtration up to 1um, thereby intercepting and filtering impurities and suspended particles in the water.

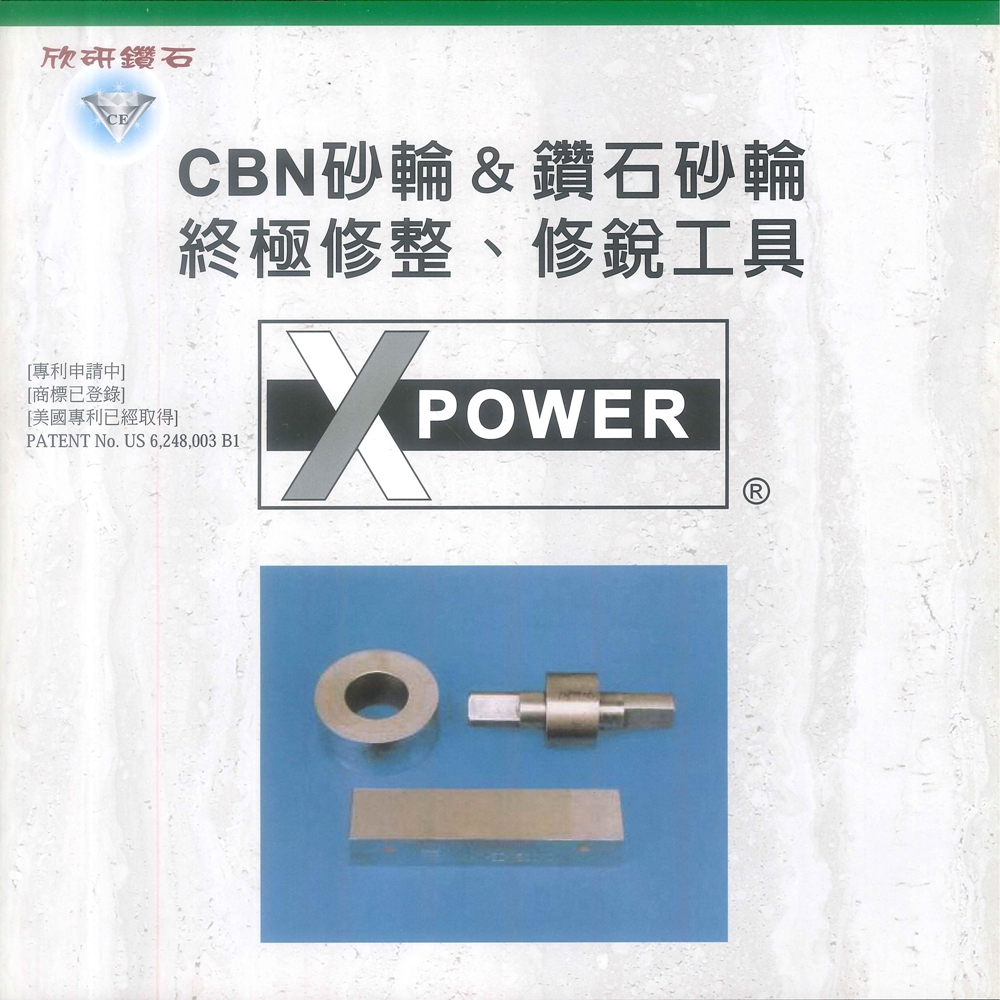

CIN EY DIAMOND WHEEL COMPANY

Product Description :

We distribute the X-POWER superhard abrasive wheel dresser from San-Ei Seiko of Japan. This dresser efficiently and simultaneously dresses (eliminates runout and reshapes) and sharpens (refines) superhard abrasive wheels. Custom shapes and sizes are available to meet customer needs.

The X-POWER's features include:

1. Simultaneous dressing and sharpening of superhard abrasive wheels (CBN and diamond wheels).

2. Highly effective not only for resin-bonded superhard abrasive wheels but also for ceramic-bonded and metal-bonded superhard abrasive wheels.

3. Significantly reduced dressing time compared to traditional methods (such as soft steel grinding or dressing with conventional WA wheels).

4. Excellent cutting quality after dressing because the X-POWER removes the bond during grinding.

5. Simple construction and operation, requiring no special equipment.

6. Flexibility: Customizable shapes to suit various applications and compatible with all equipment.

7. Single-process dressing: A single dressing operation using a dressing tool of the same shape as the finished product significantly increases equipment uptime.

8. Elimination: Eliminates dust generated by traditional grinding wheels such as WA and GC, contributing to environmental protection and improving operational safety.

11 standard sizes of X-POWER dressers are available; please refer to the attached images. Custom sizes and shapes can also be manufactured to meet specific needs.

The attached catalog provides a comparison of the dressing and sharpening effects of CBN170N100 (resin-bonded) grinding wheels using the soft steel grinding method (S50C) and X-POWER (model SX-A1) methods.

We also provide experimental data showing that the dressing effect of X-POWER on CBN400 grinding wheels with different bonds is dozens of times greater than that of S50C. A comparison of the dressing ratio of CBN grinding wheels and diamond grinding wheels using X-POWER is also available.

Finally, we presented another experiment: using an X-POWER (model SX-D1) dresser with a BN170P100BS60-10 grinding wheel, and moving a dressing block left and right against the wheel, we varied only the wheel's peripheral speed in the dressing conditions, resulting in different amounts of wheel reduction, dressing block reduction, and dressing ratio. Based on the experimental records, a wheel peripheral speed of approximately 450-750 m/min is recommended for dressing.

Through the information in this catalog, we hope to provide you with a deeper understanding of the San-Ei Seiko X-POWER dresser we distribute. Industry professionals are welcome to contact us for more detailed product information and pricing.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Created to meet the demands of modern welding, MAXWELD combines a stylish appearance with outstanding performance. Focused on space optimization, it makes your workspace more spacious and efficient. MAXWELD is the world's first model to adopt a large-area airflow design, specifically designed for high-temperature environments within factory facilities. This unique airflow design ensures that the equipment maintains effective cooling even under high-temperature conditions. Additionally, MAXWELD comes equipped with dust-proof cotton to effectively prevent dust from entering, ensuring the stable operation and extended lifespan of the equipment.

JASON AUTOMATION CO., LTD.

Product Description :

As part of Emerson Automation Solutions, AVENTICS is one of the world’s leading product brands for pneumatic components and systems. The pneumatic engineering brand provides products and services for industrial automation, as well as the food, packaging, medical, and energy technology industries. For our pneumaitcs brand, we also develop solutions for the commercial vehicles, marine, and railway technology sectors.

YI CHANG MACHINERY CO., LTD.

Product Description :

This video features the Yi Chang Machinery model HD750 hydraulic automatic drilling machine assemble with a cam indexer combination. This combination not only achieves the rapid completion of multi-hole drilling requirements on a single workpiece but also significantly improves work efficiency, making operations much easier.

This hydraulic automatic drilling machine utilizes its efficient cam indexer , allowing you to accomplish multi-spindle drilling in a short amount of time. Whether it's for mass production or individual pieces, the machine proves to be exceptionally productive. Operating this machine is straightforward, even for beginners, and its high-efficiency design enables you to tackle work challenges with ease.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!