Theme

Digital Transformation

Green Transformation

YIH KUAN ENT CO., LTD.

Product Description :

The Plano Milling Head (Gantry Milling Head) are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines. Uses include rough milling, finishing milling, boring holes... and other processing requirements.

The left and right vertical milling heads offer excellent flexibility and adaptability. Their adjustable angles and swivel capabilities enable operators to perform angular milling, drilling, and other complex operations with ease. They are compatible with different milling machines, providing a seamless integration into existing setups or as a valuable addition to new milling machine installations.

1. IK milling heads can upgrade or replacement your existing machine body, milling machine or special machine and also it can bring more stable and high-quality machining benefits for work piece cutting.

2. It is used for mold manufacturing or precision processing.

3. The machine processing for travel is 320 mm. We also provide “No slide” format.

4. This product is used in Gantry (Plano) Milling Machine (vertical / horizontal), suitable for heavy metal cutting.

5. Plano milling head series offer accessory head for you to optional.

It will apply for multi-angle machining to upgrade efficiency and longer machining range.

6. This product of standard motor is 10HP. We also offer 12.5HP for you to optional.

7. Offer pneumatic blade locking device, bearing guide screw, pneumatic leveler for you to optional.

8. There are 10 models in IK Plano Milling Machine Head Series.

PEIPING PRECISION ENTERPRISE CO., LTD.

Product Description :

*Automatic spindle polishing control.

*Keep the precision of spindle and no damage to spindle body.

*One setting for the maximum convenience of operation.

[After Use]

*Extend the life of cutting tools.

*Increase workpiece accuracy.

*Reduce the spindle vibration and extend the life of spindle.

YIH KUAN ENT CO., LTD.

Product Description :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.

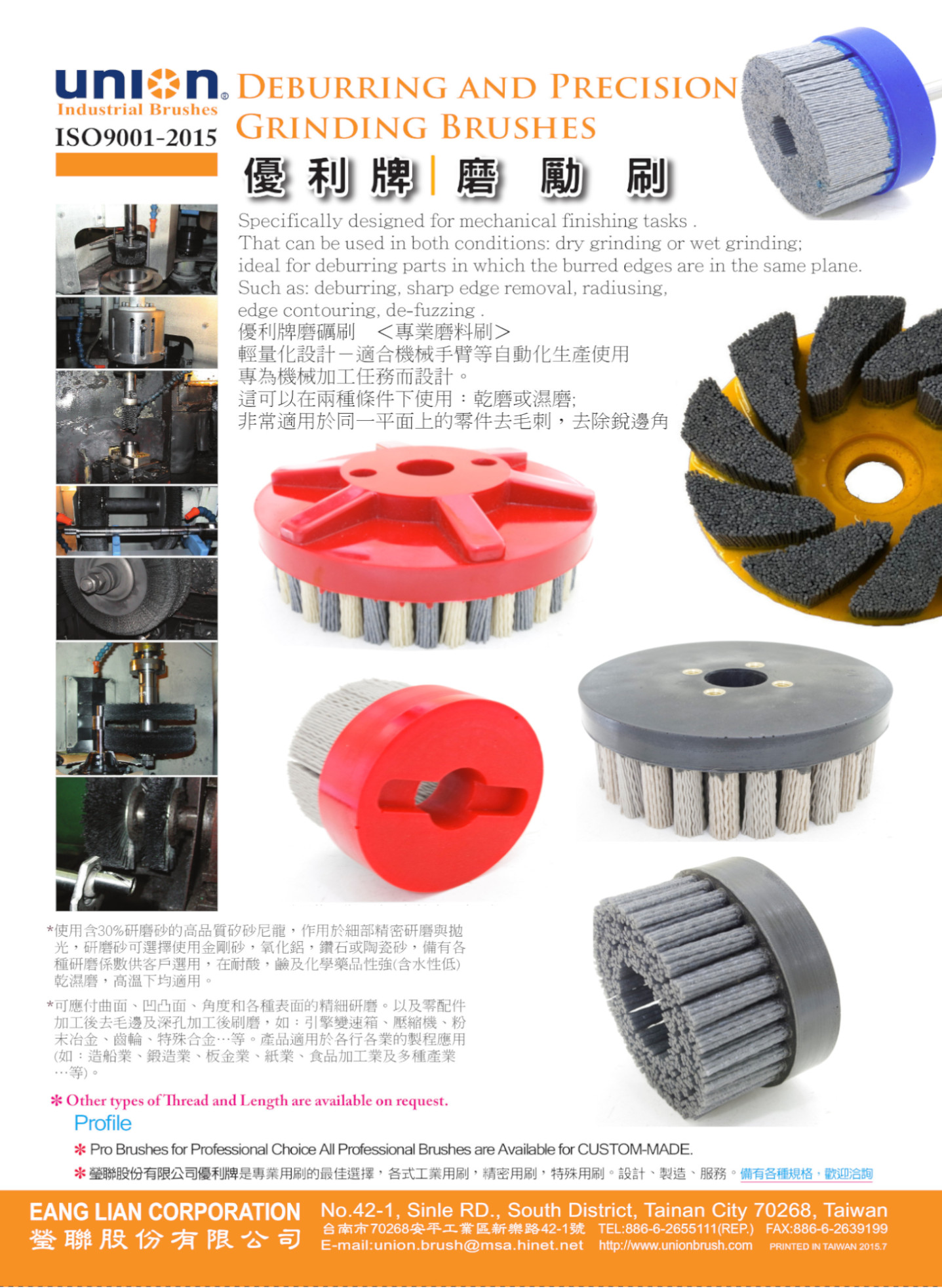

EANG LIAN CORPORATION

Product Description :

Professional Abrasive Brushes-Specifically designed for mechanical finishing tasks .

Specifically designed for mechanical finishing tasks .

That can be used in both conditions: dry grinding or wet grinding;

ideal for deburring parts in which the burred edges are in the same plane. Such as: deburring, sharp edge removal, radiusing,

edge contouring, de-fuzzing .

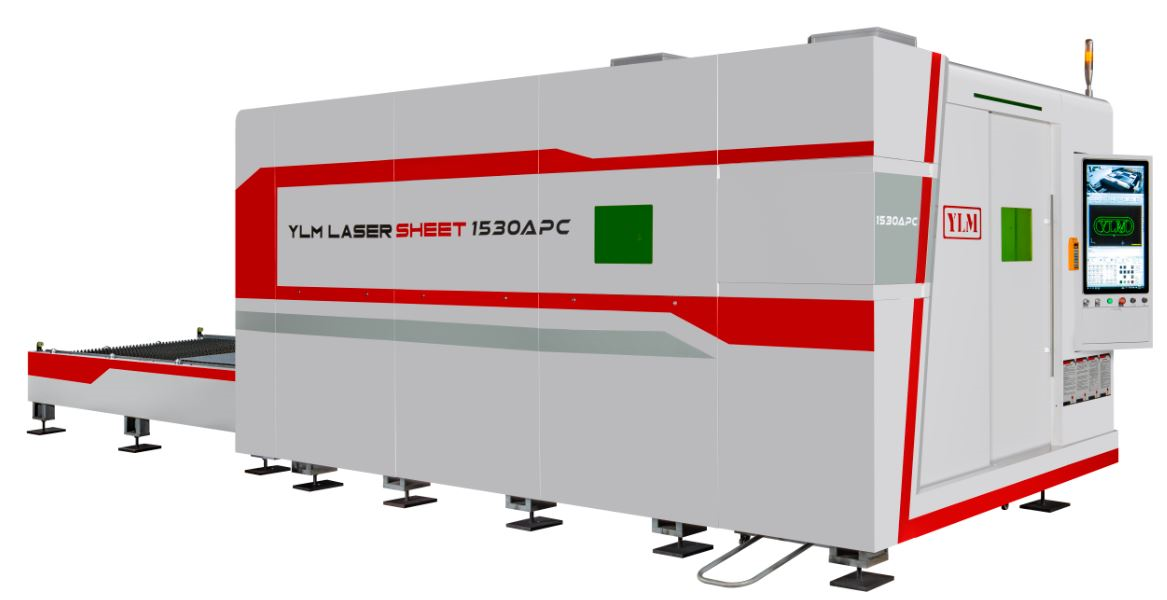

YING HAN TECHNOLOGY CO., LTD.

Product Description :

Suitable for cutting various metal sheets

■Maximum cutting thickness of metal sheet varies with the laser power.

■Upon customer request, the machine can be designed with a work piece platform as mechanism(optional). It helps to reduce work piece loading/unloading time, which in turn upgrades operation efficiency.

■Large laser power, high efficiency and high productivity.

■Equipped with an intelligent digital controller featuring humanized control, which is easy to learn and operate.

■The specially designed software allows the operator to design the graphs on characters with ease, then machining can be conducted immediately.

■Enclosed splash guard

■Fast machining, power saving, outstanding safety protection, low trouble and easy maintenance.

For cutting commonly used metal sheets such as:

■Carbon steel sheets

■Alloy steel sheets

■Galvanized steel sheets

■Stainless steel sheets

HOLDING ELECTRIC CO., LTD.

Product Description :

Holding Magnetic tools honing edge machines can achieve the following effects in a short time.

1. Trim the chipped and sawn edges to remove burrs and burrs.

2. Achieving consistent rounding processing, making the blade smooth, smooth, and sharp, durable.

3. Improve the surface finish and surface roughness of the workpiece.

4. Increase tool life and reduce the probability of chipping. The measured value can increase the tool life by up to 65%.