Theme

Digital Transformation

Green Transformation

LITZ HITECH CORP.

Product Description :

1. 集工程集約的車-銑削複合加工,實現<br />一次裝夾多面加工。<br />2. 帶來高精度、高效益,可產生高效益。<br />3. 可更加快速、更加容易實現縮短交期。<br />4. 降低投資人力,能源成本帶來高投資報酬率。<br />5. 可發揮2軸車床+加工中心互為補助的投資效果。

MATECH INDUSTRIAL CO., LTD.

Product Description :

本數控橢圓車床係為解決汽油機與柴油機活塞的中凸變橢圓裙部之加工而設計的。

本機特性

*本數控橢圓車床採用線性伺服橢圓產生器,配合非接觸式0.0001mm超高解析度

回饋系統,具備高響應頻率、高精密度、高剛性等特點。

*由於此設備採用高效能控制核心及極短取樣時間的新一代控制器,可以獲得更快速

且精準的切銷路徑控制。

*本機部份採用全閉環式0.001mm光學尺回饋系統,近一部確保最家定位精度,並能

有效的消除熱干擾。

*新一代整合式橢圓控制器,由於不在需要資料傳輸,因此可以避免因為傳輸而導致的

雜訊干擾或資料遺失。

*編程軟體採用(看圖輸入法)編寫,操作者無須再耗費長時間學習,只要依照活塞圖面

標示的尺寸,輸入安加橢圓控制器即可,型線及相關橢圓路徑則全由控制器處理。

MAROX TOOLS INDUSTRIAL CO., LTD.

Product Description :

【External Turning Tools with coolant】

AACLN、AATJN、AATQN、AAWLN、ADCLN、ADDJN、ADDQN、ADTEN、ADTJN、ADTQN、ADVJN、ADWLN、AMCLN、AMDJN、AMTJN、AMVJN、APCLN、ASCLC、ASDNC、ASDJC、ASTUP、ASVJB、ASVJC、ASVJP、ASVKB、ASVKC、ATJNR、AWLNR

【Boring Bar with coolant】

L-SCLC-V、L-SDUC-V、L-STLC-V、L-STUP-V

【Threading Tools with coolant】

ASER、ASER-WP、ASER-NA

【Grooving holder with coolant】

ACGWS、AEVSC/M、ADGT、AGHR、AGNDMR、AGHSR、AGWC、AKGD、ASLAL-38、ATGTR、ATSE、ATTE、AWGCSM、AUASR、AUSR

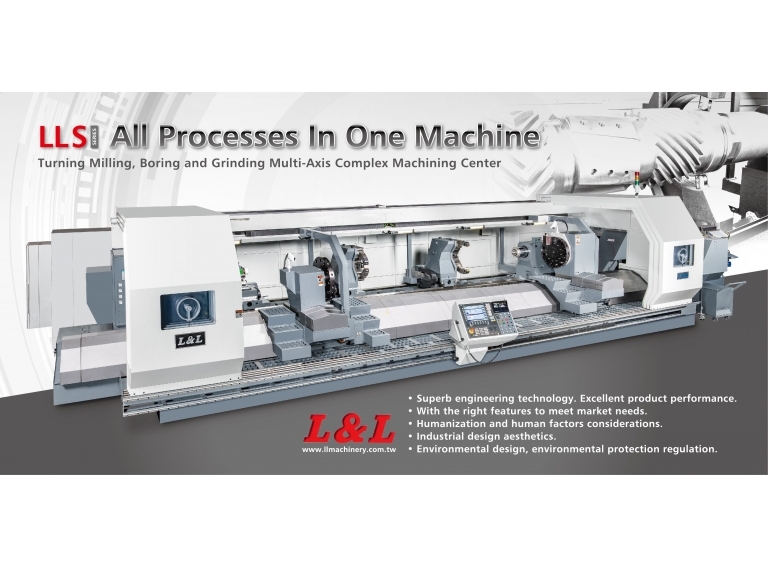

L & L MACHINERY INDUSTRY CO., LTD.

Product Description :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.

FONGEI INDUSTRY CO., LTD.

Product Description :

-It can process various chips created by complex machining.

-Equipped with a filter system for processing cutting fluid with 0.5mm filtrating accuracy.The roller filter screen features a self-cleaning function to ensure the dependability of filtration.

-Equipped with an industry-leading overload protection device the extends the parts service life of the chip conveyor.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

【CROSS DRILLING/MILLING UNIT, 3-SPINDLE】

Speed ratio : 1:1

Maximum speed : 8000RPM

Tool clamping : ER11M

【DRILLING/MILLING UNIT FOR SUB SPINDLE】

Speed ratio : 1:1

Maximum speed : 8000RPM

Tool clamping : ER11

Machine :

33mm : SR-20R : STRB111203

36mm : SB-20R : STBB111201

47mm : SR-32J : STRB111301

HC FENG CO., LTD.

Product Description :

Oil Slick Treatment

Plug-In Free

No Consumables

Water Purification

Removes Odor

Optional Features

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

Spindle nose A2-6 with 8” inch chuck for both spindles. The bar capacity of the main spindle is up to 52mm. Spindle uses high-power built-in motor with a maximum torque of 292Nm which for heavy cutting and surface milling operations. The capacity of the Y axis is ±50mm, which allow offset processing and increase the speed of milling.

Max. swing: 790mm

Max. turning diameter: 300mm

Max. turning length: 770mm

Bar capacity: 52mm

X1-axis travel: 235+15mm

X2-axis travel: 220+10mm

Z1-axis travel: 770mm

Z2-axis travel: 790mm

B-axis travel: 770mm

Y-axis travel: ±50mm

Spindle speed(Main/Sub): 4500rpm

Spindle nose(Main/Sub): A2-6

Spindle motor power(Main/Sub): 25kw

Number of tool stations: 16T

VICTOR TAICHUNG MACHINERY WORKS CO., LTD.

Product Description :

.One piece 30˚ slant bed with large swing diameter

.10" Power chuck / 3500 rpm (A260)

. Z-axis travel 750 mm

.High thrust force by small pitch ballscrew

.High rapid feed 24 m/min (Z-axis)

.Shortened belt driven spindle

.Digital tailstock

.8” chuck for subspindle (opt.)

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.