Theme

Digital Transformation

Green Transformation

AUTOCLAWS PRECISION MACHINERY CO., LTD.

Product Description :

1. Suitable for round-bar shape objects to clamp before cutting process.

2.Using the advanced high-strength alloy steel, the key components have been treated with hardening which is strengthening the structure and enhancing the stability with accuracy and durability.

3.Large caliber design allowing the bar material go through, furthermore, it can be complemented to automatic processing eqipment for enhancing the machining efficiency.

4. The chucks complement the rotary hydraulic cylinder to provide a stable pressure for various chucking conditions.

5. Professional precision grinding makes it high-precision, precision repeat clamping accuracy, high clamping force.

YA LIANG INDUSTRIAL CO., LTD.

Product Description :

This Drill Chuck can clamp drill bit, taps and end mill easily. Clamping force can reach 400-800Kg-cm. Change cutter by Hexgoan key. Innovative design decrease frequency of touching by hand directly. Fine accuracy and through chuck coolant system.

TAIKI INDUSTRIAL CO., LTD.

Product Description :

The soft jaws - 1.5mm x 60 Degree- standard type (SJ08037B) is used in the CNC lathe.

According to different process terms, customers can choose varied sizes to be more convenient, and avoid unnecessary correction movement.

Available in steel(S50C)

YA LIANG INDUSTRIAL CO., LTD.

Product Description :

S-TYPE Special heavy duty model #122

Extremely high accuracy and precision design, suitable for CNC machining and machining center. All parts are ground, heat treated, surface treated and under specific QC condition.

H-TYPE Heavy duty model #123

Industrial design especially for milling machines and drilling machines.

All hardened parts ensure long life and safety while in operation.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

Pneumatic pressure status.

Support Front/Rear chuck configuration.

Abnormal pressure loss alarm.

Wireless signal transmission.

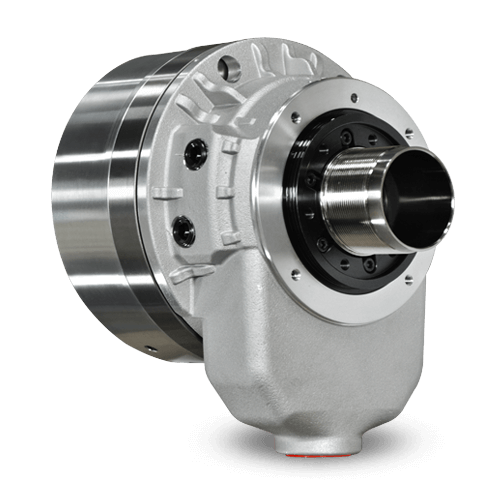

AUTOCLAWS PRECISION MACHINERY CO., LTD.

Product Description :

1.Through-hole design facilitates automation center feeding or long bar material processing convenience.

2. Safety Device: Whole series of our cylinders are equipped with check valve as the security device, furthermore, the back-lock design of the cylinder body can strengthen the structure rigidity and decrease the counter-force generated by thrust or pushing force, either the front-lock also can be applied to the cylinder body as well.

3.Short structure design: The short structure design will strengthen the structure,reduce the torque reaction and also decrease both the load of the spindle and the interference when assembling.

4.Light Weight: The cylinder made of high-intensity aluminum alloy and high-strength alloy steel, the structure design can lighten the weight and reduce the rotation inertial

effects,and not only strengthen the structure but also increase the cooling effect.

5.Durability: Adopting high quality steel alloy through hardening treatment and high accuracy professional grinding technology go with superior quality seals, the cylinder can achieve high intensity, high rigidity and well durability features.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.