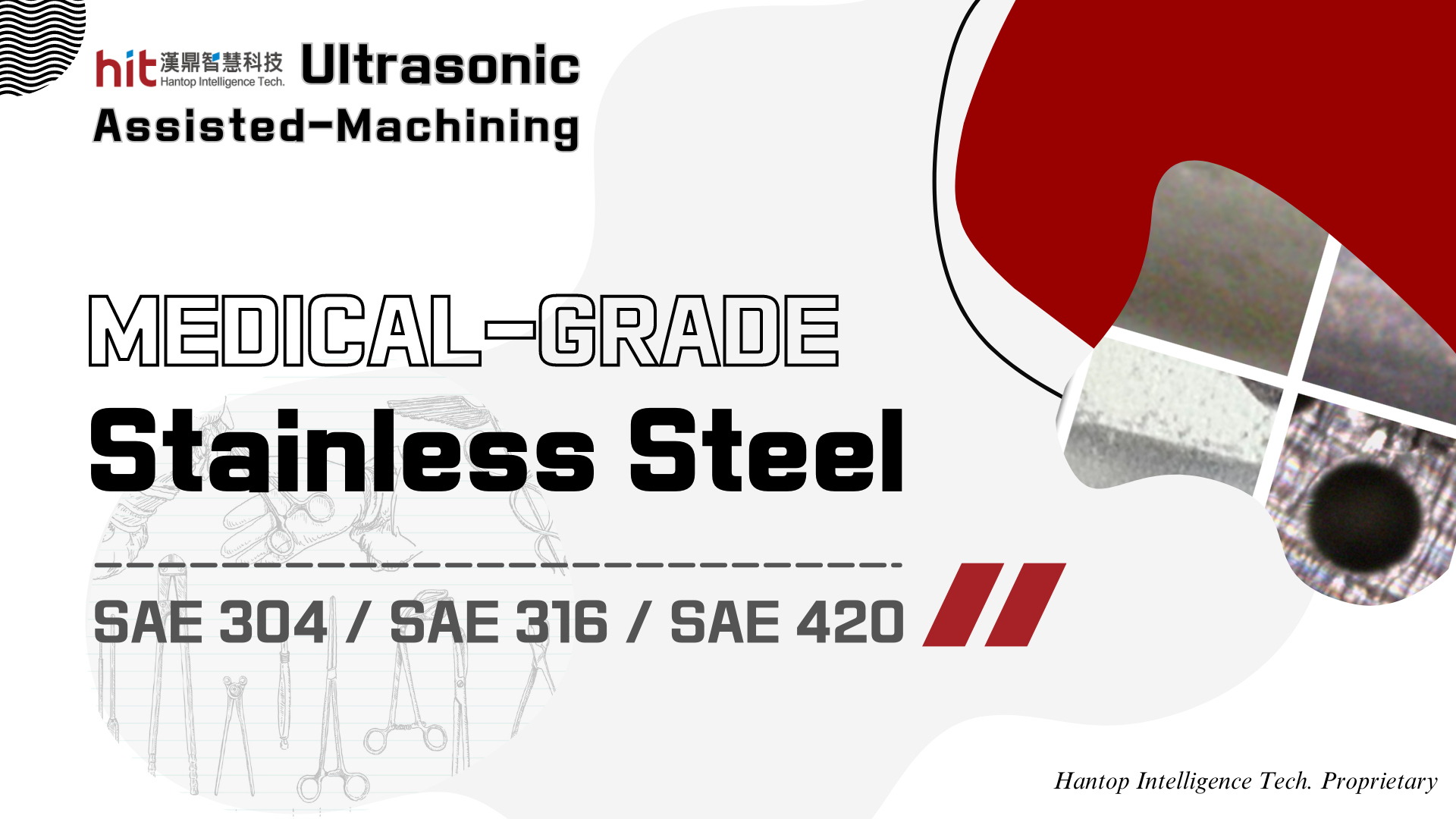

What Does HIT Ultrasonic Machining Bring to Medical-Grade Stainless Steel Machining?

[Ultrasonic High Frequency Oscillation]

HIT's ultrasonic-assisted machining technology provides the superimposition of the tool rotation with a high-frequency oscillation in longitudinal direction, generating over 20,000 times of micro-vibration per second. The mechanism helps reduce cutting forces and facilitates chip removal process.

The high-frequency oscillation in longitudinal direction allows for an intermittent contact between the tool and workpiece. This helps eliminate accumulative cutting heat around the tool tip, which results in great reduction in tool wear.

[Reduction in Cutting Force]

The reduction in cutting forces not only decreases frictions between the tool and workpiece, but also allows cutting speed and feed rates to be increased. This mechanism along with the high pressure (up to 70bar) coolant through spindle (CTS) feature also helps lower the heat generated during the machining process. It greatly improves the workpiece quality and stability in tool life and saves a huge amount of energy and processing time.

[Easier Chip Removal Process]

Facilitating chip removal or chip evacuation process also reduces frictions on both tool and workpiece caused by excessive amount of accumulative chips. Especially when the chips are long and stringy, it may lead to built-up edge (BUE) or chip re-cutting situations, which worsens workpiece quality and endangers tool life. The reduction in cutting forces with HIT's ultrasonic high-frequency micro-vibration allows the tool to cut off the material more easily with easier chip evacuation process. The elimination of entangled, accumulative chips also contributes to better workpiece quality and longer tool life.

[Ultrasonic High Frequency Oscillation]

HIT's ultrasonic-assisted machining technology provides the superimposition of the tool rotation with a high-frequency oscillation in longitudinal direction, generating over 20,000 times of micro-vibration per second. The mechanism helps reduce cutting forces and facilitates chip removal process.

The high-frequency oscillation in longitudinal direction allows for an intermittent contact between the tool and workpiece. This helps eliminate accumulative cutting heat around the tool tip, which results in great reduction in tool wear.

[Reduction in Cutting Force]

The reduction in cutting forces not only decreases frictions between the tool and workpiece, but also allows cutting speed and feed rates to be increased. This mechanism along with the high pressure (up to 70bar) coolant through spindle (CTS) feature also helps lower the heat generated during the machining process. It greatly improves the workpiece quality and stability in tool life and saves a huge amount of energy and processing time.

[Easier Chip Removal Process]

Facilitating chip removal or chip evacuation process also reduces frictions on both tool and workpiece caused by excessive amount of accumulative chips. Especially when the chips are long and stringy, it may lead to built-up edge (BUE) or chip re-cutting situations, which worsens workpiece quality and endangers tool life. The reduction in cutting forces with HIT's ultrasonic high-frequency micro-vibration allows the tool to cut off the material more easily with easier chip evacuation process. The elimination of entangled, accumulative chips also contributes to better workpiece quality and longer tool life.

Hantop Intelligence Technology

Brand Name:

Hantop Intelligence Technology

Booth Number :

P1232

Contact Information :

- www.hit-tw.com

- +886-4-22850838

- +886-4-22850836

- Room 921, Applied Science & Tech. Building, No. 145 Xingda Road, South District, Taichung City 402, Taiwan