展覽主題

數位轉型

綠色轉型

崧嘉實業有限公司

產品描述 :

●精密鉸孔神器-浮動鉸刀柄,可解決以下問題:

1. 孔的直線行差

2. 鉸刀不耐用

3. 孔的尺寸擴大,尺寸精度達不到要求

4. 孔的中間大,兩頭小,圓柱度達不到要求

5. 內孔表面粗糙度達不到要求

6. 大批生產時無法保證孔徑尺寸的一致性 。

●浮動鉸刀柄的特點:

1.可透過360度浮動讓鉸刀對準下孔徑,避免對不準而造成擴孔或縮孔

2.徑向振幅抑制在5μm以下

3.提高鉸孔光潔度

4.彌補車床公差,提高鉸孔精密度

5.提高鉸孔的直線度和圓柱度

●浮動鉸刀柄可應用加工機械:鑽床、立式加工中心、研磨機。 可夾持工具:鉸刀、滾光刀

**產品連結→→https://www.songgia.com.tw/tw/products/other-tools/floating-reamer-holder

發得科技工業股份有限公司

產品描述 :

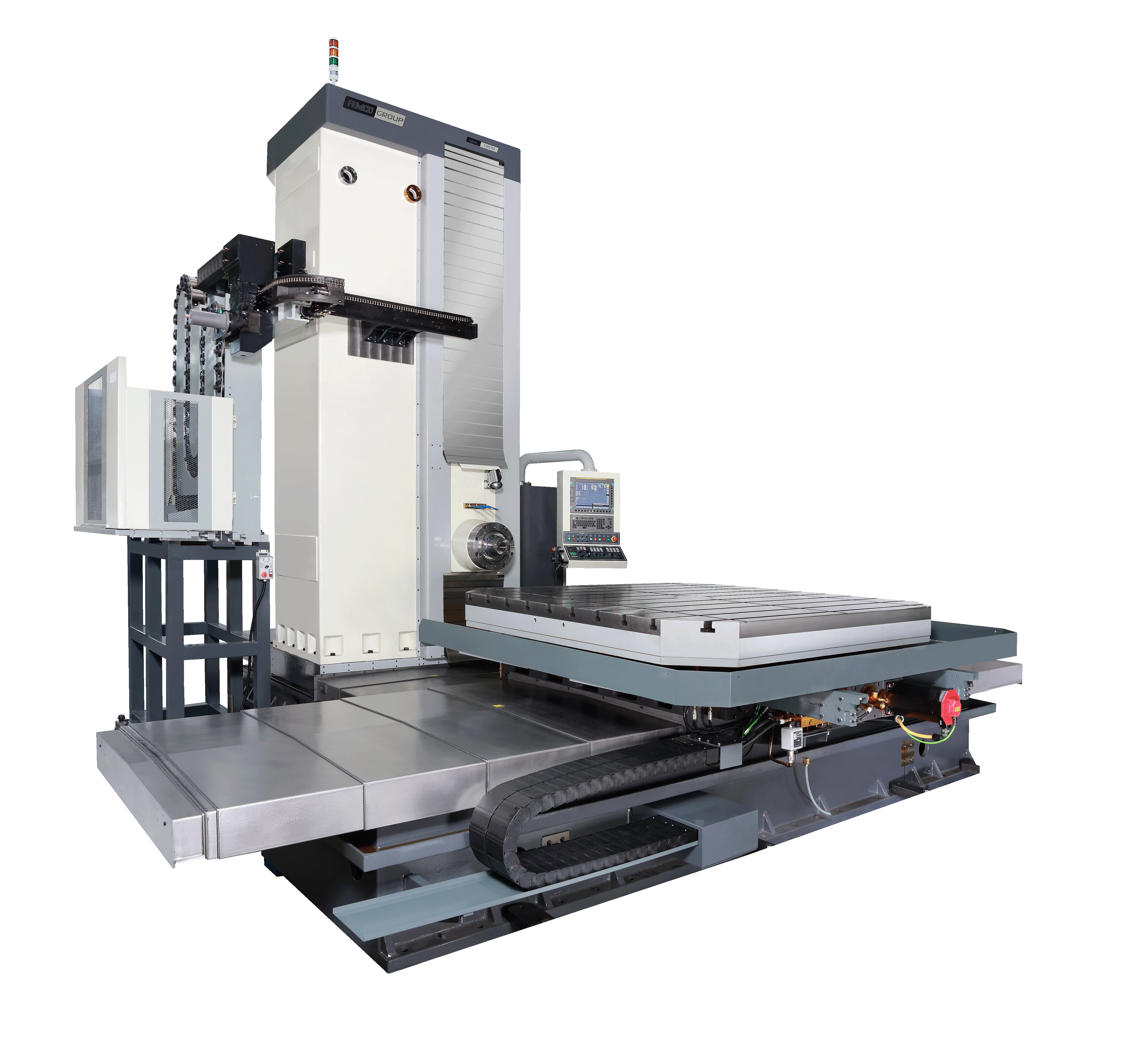

【臥式搪銑床】

BMC-135TN-135mm主軸直徑 動柱式設計

➣大型工件加工結構-可任意搭載X/Y/Z軸行程,彈性化選擇,更貼近使用者需求。

➣大型搪銑床代表之一。

針對航太複材、汽車鈑件複材等高硬度材質,大主軸轉速與扭力,搭配高承載的工作台結構,

對加工性能、精度與穩定度表現俱佳。

產品規格

BMC-135TN

工作台橫向行程 ( X ):3000/4000(option) mm

主軸箱上下行程 ( Y ):2500/3000(option) mm

動柱縱向行程 ( Z ):1500/2000(option) mm

————————————————

工作台尺寸:2200 x 2200 mm

工作台最大荷重:15000 kg

————————————————

主軸

行程(W):800mm

直徑:135mm

馬達 (連續/30分):30 / 37 kW

低速轉速:30 / 37 kW

高速轉速:579- 3000rpm

————————————————

機械外觀尺寸

高度:5080/5525 mm

佔地面積(寬×深×高):7200 x 7500 / 8200 x 8000 mm

機械淨重:33000/34000 kg

高明精機工業股份有限公司

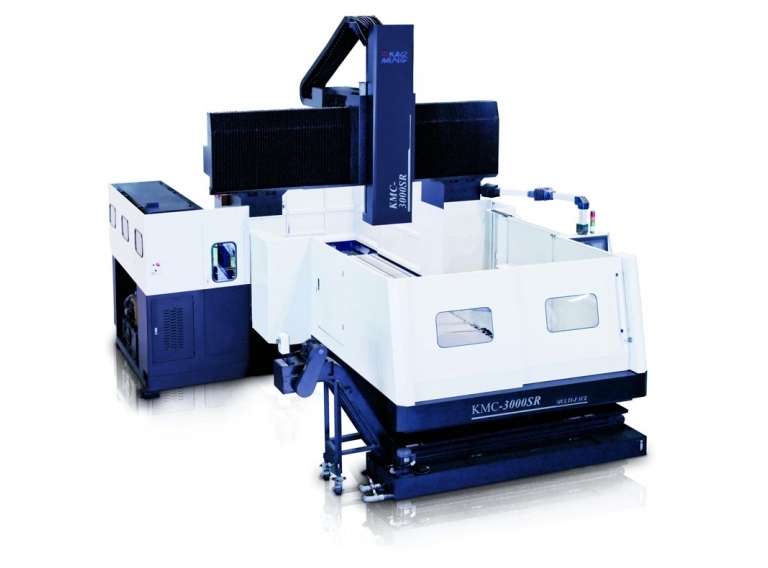

產品描述 :

1. 三軸採用方形硬軌設計,滑動件為全行程支撐,無懸伸下垂之問題,結構剛強適合重切削。<br />

<br />

2. 門寬2.1米以下,底座採用雙軌設計;門寬2.3米以上,底座採用四軌之滑動與滾動複合化設計。<br />

<br />

3. Y軸橫樑為階梯之軌道設計,段差70mm確保加工精度與穩定性。<br />

<br />

4. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

5. Y、Z軸滾珠導螺桿之安裝,其頭座與尾座係與橫樑及床鞍鑄成一體,確保最大剛性及精度。<br />

<br />

6. 機械式扭力限制器安全裝置,可避免機器在受到意外碰撞或操作錯誤時,重要機件不會因此被破壞。<br />

<br />

7. 刀庫為油壓分度馬達傳動;換刀臂之旋轉為油壓搖擺馬達驅動,確保ATC換到系統之快速、精確及穩定性。<br />

<br />

8. X軸8米以上四軌床身為線性導軌傳動,中央為主支撐兩側為滾子式履帶軸承輔助支撐,以增加傳動效率。<br />

善化工業股份有限公司

產品描述 :

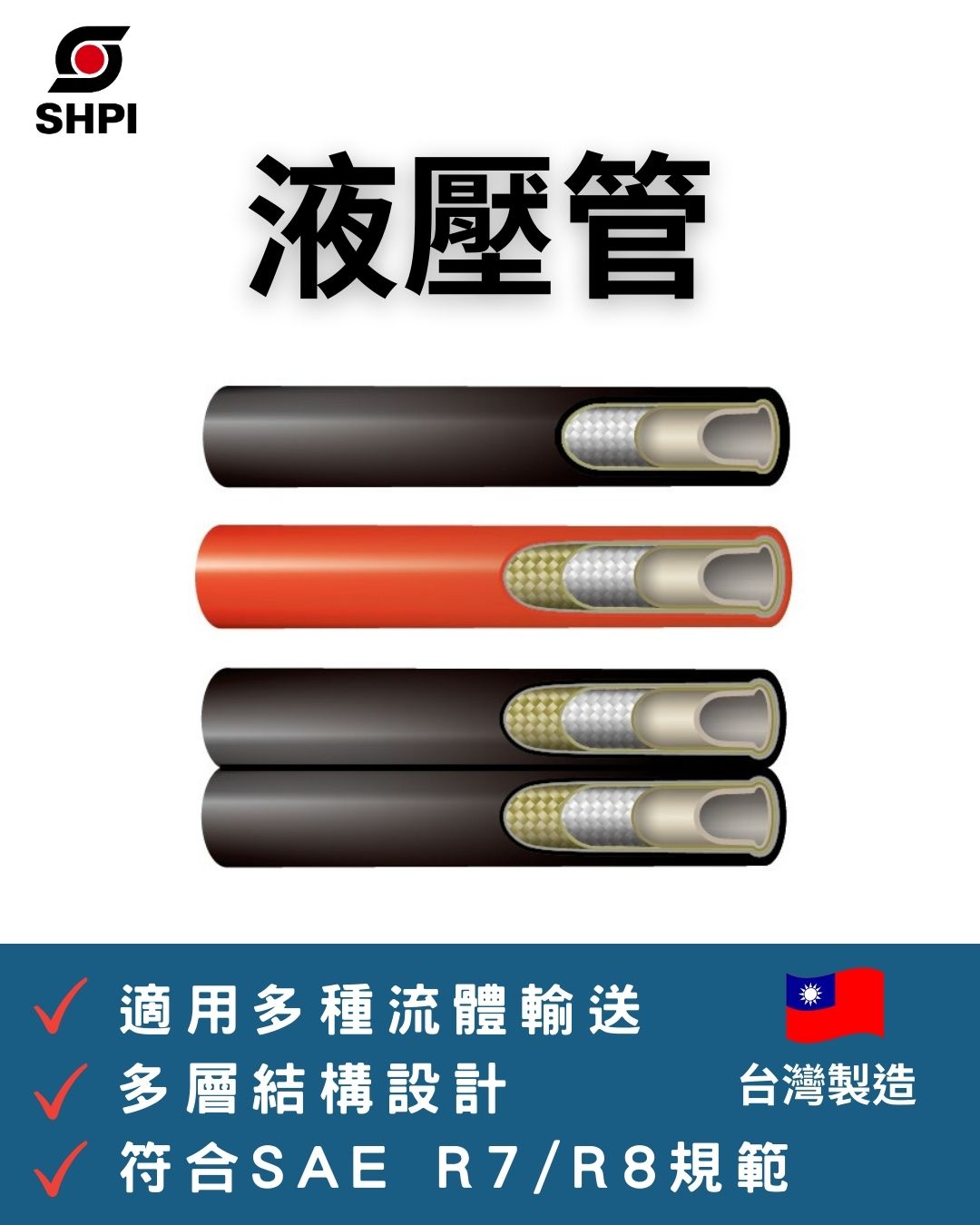

善化工業股份有限公司專業生產符合 SAE 100R7 與 SAE 100R8 規範之高壓油管,提供多樣化的尺寸、顏色、配置與包裝形式,滿足不同產業與設備應用需求。

本產品具有重量輕的特性,約為傳統橡膠管重量的一半,於承受工作壓力時仍能保持良好的曲線穩定性,不易變形。管材採用具耐候性、耐磨性與耐油性的特殊材料製成,同時具備良好的酸鹼耐受能力。

外管顏色可依需求選擇,以利設備管路的顏色管理;亦可提供導電型與非導電型 格,以符合不同設備與作業環境的安全需求。

在應用方面,本產品可作為傳統橡膠管的替代方案,廣泛應用於高壓液體、高壓氣體、噴塗設備、清水溝車、農業機具、轉向系統、船舶設備等各類液體與氣體配管系統。