展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

SONG GIA INDUSTRIAL CO., LTD.

製品の説明 :

4 Key Advantages:

●. High-Precision Structural Design

Featuring a rigid body combined with precision grinding, this design enhances machining stability and concentricity to ensure consistent accuracy in every operation.

●. Through-Coolant Direct to Cutting Point

Integrated through-coolant channel effectively removes chips and prevents entanglement, extending tool life and maintaining cutting performance.

●. Full Range of Models with Flexible Compatibility

Compatible with a wide range of sliding head machines. Custom configurations are also available to meet specific machining needs.

●. Locally Manufactured

Designed and made in Taiwan, delivering stable quality with professional technical support always on standby.

https://www.songgia.com.tw/en/products/live-tools-for-cnc-lathes/bmt-series

EQP SERIES CO., LTD

製品の説明 :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g

7-LEADERS CORP.

製品の説明 :

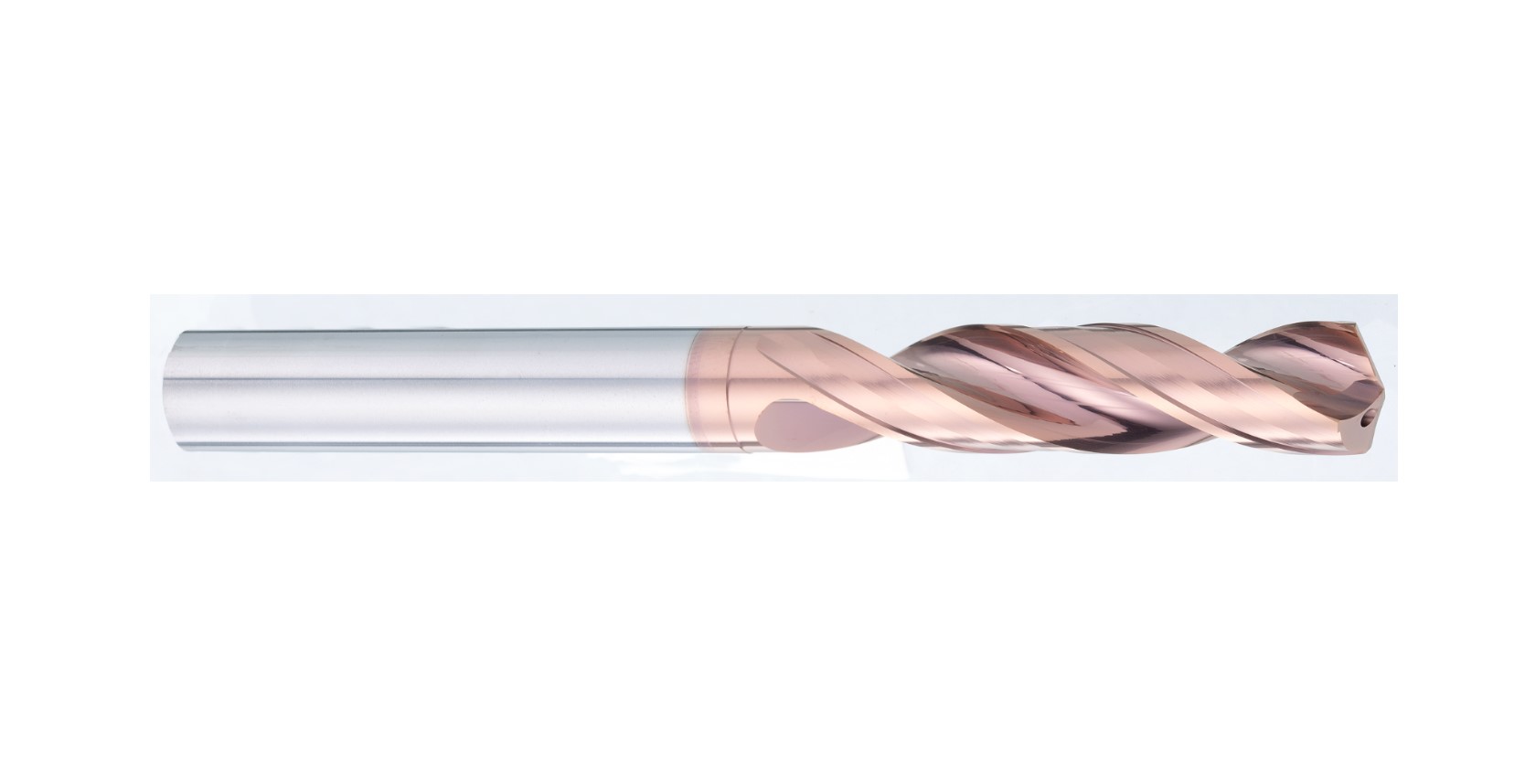

JIS 3XD Drills with Oil-Feed

140° S-shape drill tip design to reduce axial force.

Design with groove shape to provide higher chip removal rates.

Good wear resistance and lubrication with Nano multilayer coating.

Oil-feed design could reduce temperature effectively and increase chip removal rates during cutting process.

Application for drilling with Steels which under HRC48, Cast Iron…etc.

Suitable for drilling with 3XD depth.

Lanza International Co., Ltd.

製品の説明 :

Global Supply Chain Reshaping|Taiwan’s Hardware Industry Moves Toward Intelligence and Sustainability

In an era of global supply chain restructuring and accelerated smart manufacturing transformation, Taiwan has emerged as a vital hub in the global hardware industry—powered by its outstanding precision manufacturing capabilities, flexible supply chain system, and innovative R&D strength.

The 2025 Taiwan International Tools & Hardware Expo x International Hardware Expo Taiwan (TiTE x IHT) will be grandly held from October 21 to 23 at the newly completed Taichung International Convention and Exhibition Center.

With "TEAM TAIWAN" as its core theme, this year’s edition brings together Taiwan’s industrial cluster strengths and global sourcing demands to create a one-stop sourcing platform for international buyers, reinforcing Taiwan’s role as a central force in the global hardware supply chain.

MATRIX PRECISION CO., LTD.

製品の説明 :

2080/3080 applies the FANUC controller and high speed grinding spindle,it will design the tooth profile and grinding parameters flexibly through the intelligent

conversations window software. The machinable

workpieces include the standard worms(ZK, ZI, ZN & ZA), dual-lead worms, ZC (Niemann) worms, thread plug gauges and rolling

dies. The high efficiency and high-precision machining performance meet the worldwide

top brand products in this field. THW-2080/3080 is your best choice.

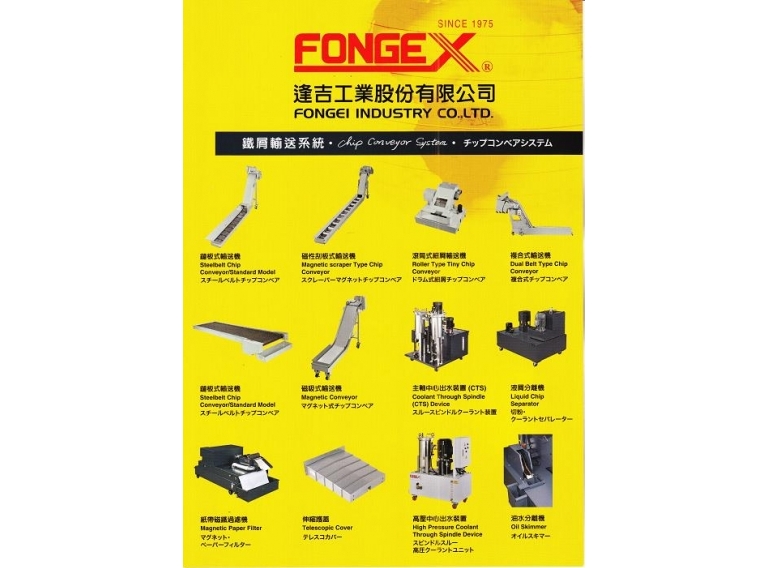

FONGEI INDUSTRY CO., LTD.

製品の説明 :

Steelbelt Chip Conveyor/Magnetic scraper Type Chip Conveyor/Roller Type Tiny Chip Conveyor/Dual Belt Type Chip Conveyor/Magnetic Conveyor/

Coolant Through Spindle(CTS) Device/Liquid Chip Separator/magnetic paper Filter/Telescopic Cover/High Pressure Coolant Through Spindle Device/Oil

Skimmer