展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

FOCUS CNC CO., LTD.

製品の説明 :

45 degree slant bed one piece casting the structure with low center of gravity, easy access and work-piece changeovers. Improved chip removal helps prevent thermal deformation. Powerful 4 stage spindle bear box provides 45kW horsepower available for large diameter work-piece and heavy duty cutting. Large through hole suits numerous bar sizes. Double row roller bearing increases stability and rigidity for heavy cutting.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

ECHAINTOOL PRECISION CO., LTD.

製品の説明 :

"ECHAINTOOL is a well-known leading brand in Taiwan. It is the leading manufacturer of professional cutting tools and cooperates with the world's leading brands of cutting tools. It has multiple cutting tool products and sufficient inventory to meet the different needs of customers. The quality products are all made in Taiwan, and have won the ""Taiwan Excellence Award"" and ""Excellent Design Award"" and passed the IS0 9001 certification, which is directly recognized by many customers from the world of aerospace, automotive and mold companies.

Adhere to the promotion of our own brand ""ECHAIN"", mainly develop and manufacture all kinds of discarded cutting tools (carbide end mills, inner/outer boring tool holder, threading tool, various milling cutters, drilling tool, hole boring cutter, rapid drills, etc.) and related components are widely used in CNC lathes and milling machines for various precision machines.

The carbide end mills developed by the ECHAIN team are all produced by the German WALTER five-axis machine to obtain the best quality and effectively meet the needs of the industry. "

TSYR TZUN INDUSTRIAL CO., LTD.

製品の説明 :

The running sound of the DC brushless motor is very low, it’s not like the carbon brush motor produce noise.

The machine can use single-phase voltage (220V or 110V), so it’s easier for user to find a single-phase power socket.

With eight speeds (max. 698 rpm, mini. 46 rpm), it’s good for the operator to

choose the speed according to the hardness of the workpiece and the size of the hole.

Drilling sleeves and tapping torsion fixture are designed with quick connectors, which can be quickly replaced to improve work efficiency.

GSTC TECHNOLOGY CO., LTD.

製品の説明 :

HWR Spanntechnik GmbH is a specialist in clamping deformation-sensitive workpieces and in compensating, concentric clamping of components of any shape. Your application in focus: With more than 30 years of experience, we know your applications inside out – and we always focus on your requirements in our developments. At HWR, innovative strength meets absolute precision in execution. The result: application-optimized clamping devices that reliably meet the increasing demands of turning. Rely on solutions that are as effective as they are economical – for optimal results in your production.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ軸行程:1000x600x500 mm (39"x24"x20") inch

工作台:1250x750 mm (49"x29" )inch

最大工件:2000x1150x625 mm (79"x43"25") inch

最大工件重:4500 kg

最大電極重:350 kg

機器淨重:5700 kg

油位高度: 110-450 mm (4"-18" )inch

佔地面積尺寸(長x寬x高):4010x4050x2880 (158"x159"x113") inch

電極板至工作台面距離:430-930 mm (17"-37")

過濾箱:2

過濾網:4

容量:1900公升

3D CNC WINDOWS CE 控制器特點:

> 本系統是採用Windows CE 控制器。

> 採以對話式視窗來呈現且搭配圖片描述功能。

> 具有專門維修畫面來加快維修速度。

> 本機三軸均採用數字尺回授之全閉環迴路設計,故能使定位精度及ORBIT-CUT加工精度及效率大幅提升。

> 具有良好且簡易的操作介面。

*常用的功能鍵都在操作面板上直接使用。

*具有快速按鍵功能。

> 可加裝ATC自動換刀及加裝C軸360度分度,可自動修飾從粗加工至超細加工一次完成。

> 對話式程式,提供各種擴孔模式(各種快速尋邊,尋中心、尋基準點功能)。

> 具有較高顏色的畫質(與PC相同高畫色)。

> 可做自動多段加工(粗→中粗→中細→細→極細),最多可達10段。

> 加工條件採用加工檔案方式儲存,具有無限組加工條件,每組加工條件可直接編輯修改或儲存,編輯簡易查詢方便。

> 自動尋原點功能及多點座標記憶功能。

> 1/2設計功能及ARC自動放電波形偵測與自動調整。

> 自動中心測位自動補償,可尋孔中心尋孔最深點。定孔加工(循環式、獨立式),適合不同加工情況。放射狀、圖形、方形、直線(向量式)、錐度、45°擴孔加工。

> 三軸直線、二軸圓弧、三軸螺旋。

> 中/英文版及公/英制切換和Z軸快上、快下及慢上、慢下功能。

> 單軸側放,三軸,六種方向(平面旋轉)。

> 所有警報都可詳細描述發生的問題點、紀錄時間、日期。

> 採光學尺Close-loop位置控制,精度高。

> 自動編輯。可依材質、面積、加工深度、單側間隙、最終電流、電極磨耗等設定。

> CNC機型同樣具有傳統式等能量釋放功能,加工穩定快速,電極消耗小,表面精度均勻。

> 監視畫面加工路徑顯示和圖形顯示功能。

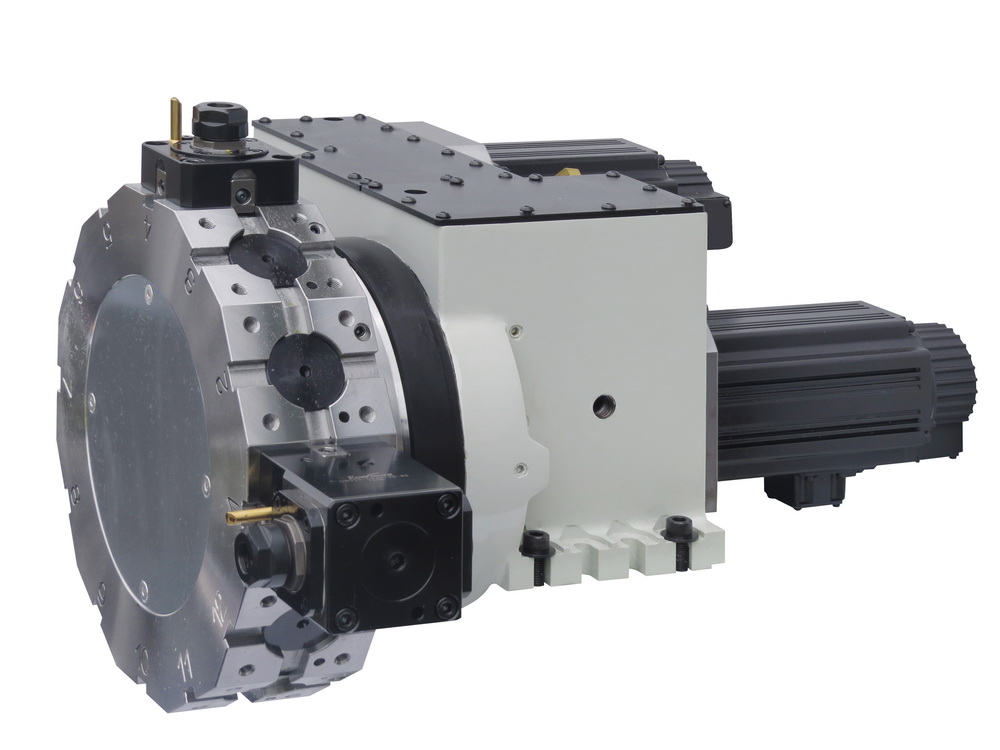

GSA TECHNOLOGY CO., LTD.

製品の説明 :

1.Max. live tool speed up to 6,000 RPM

2.Driven tool holder utilizes DIN 1809 interface

3.ndexing via 3-piece curvic coupling with hydraulic clamping , High durability; ideal for heavy-duty cutting

4.VDI/BMT turret options; accuracy 0.01mm, concentricity 0.005mm

5.Low noise and exceptional service life

CHIEN WEI PRECISE TECHNOLOGY CO., LTD.

製品の説明 :

1. Cone &angular grinding

2. Spindle &Collar grinding

3. 90 degrees rotation dresser

4. Workpiece measurement

5. Conversational format interface:diagram demonstration to edit grinding program. It is easy and faster setting grinding parameter for any new operator.

6.TD TYPE:C-Axis for CVG-4/65/8/12CTD is using build-in motor design with angle control in order to work for profile or eccentric circle.

SING CHIUN ENTERPRISE CO.,LTD.

製品の説明 :

(1) Great tensile performance, great camber.

(2) Thermal resistance range:-15℃~105℃ , Protection

degree IP68.

(3) Inner conduit is made of iron metal with zinc plating,

out layer is covered with PVC, with of waterproof

and dust proof.

(4) PT705 (3/8"~ 1 1/4") Inner conduit with copper

earth wire.

(5) According to IEC Section 351, the conduit must be

additionally attached with one grounding cable

when PT705 (1 1/2"~ 4") is constructed.

(6) Apply to conduit protection of electrical equipment

under UL standard, detection instrument, industrial

equipment and hardware work piece.

(7) Apply to electrical conduit for heavy industrial

machine motor, petrified and chemical machine,

plastic manufacturing building, power transformer

and ship manufacturing.

GSA TECHNOLOGY CO., LTD.

製品の説明 :

Dual lead worm wheel / worm shaft which allowable easy backlash adjustment。

Double bearing design suitable for heavy cutting。

One piece of faceplate and spindle design which offer rigid construction。

Large thru hole design which allowable large work piece going thru spindle。