展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

YING HAN TECHNOLOGY CO., LTD.

製品の説明 :

YTL8320G

CNC computer lathe and portal robot arm

Machine features

- Automated process control

- Mass production of extremely precise workpieces

- Visual programming made easy

- Efficient process intelligence

Machine specifications

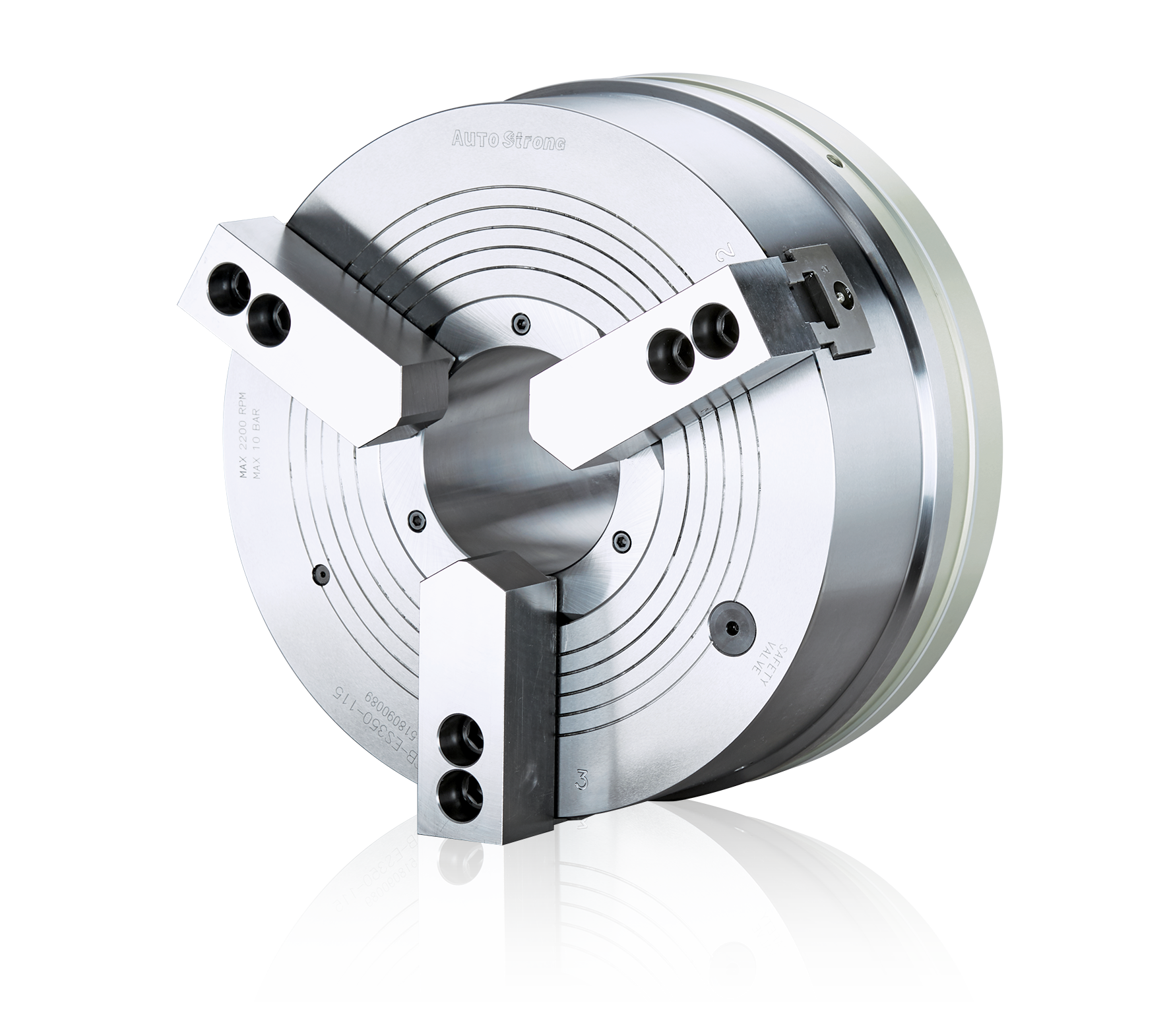

- 8-inch spindle chuck

- 45 degree slant back bed

- Z/X axis travel: 320/185mm

- Max. load of robotic arm is 4kg

- 10 station of storage capacity

MAINTECH PRECISION CO., LTD.

製品の説明 :

Axis Rotational angle C-axis ±200° A-axis ±110°

Axis Rotational torque

C-axis 700 N.m(Continuous)1410 N.m(max. ,1s) A-axis 633 N.m(Continuous)1200 N.m(max. ,1s)

Rotational speed 360° / S

A/C Clamping force 4000 N.m

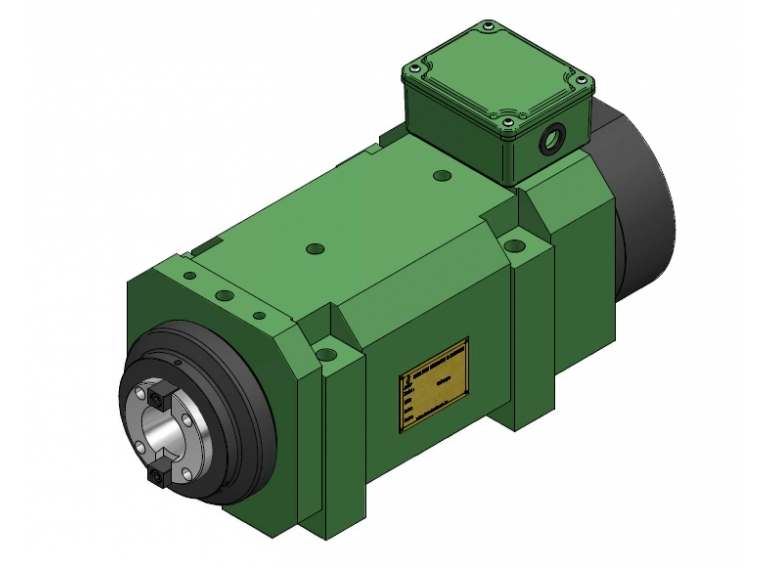

Spindle Max. speed 12000 rpm

Spindle torque 200 (S1) / 240 (S6) Nm

Spindle Power 54 kW

HUI-JING ELECTRONIC CO., LTD.

製品の説明 :

★ Multiple output type for many CNC controllers

★Multiple output types compatible with different CNC

control systems

★Optional enable micor switches for application

★Meet customers’various demands

★Optional Emergency Stop switch

★Magnetic back cover

★Dust & Water proof (IP65)

★Optimal solution

★Provide reverse polarity protection

★Easy to handle

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

製品の説明 :

The brand-new product CNC Vertical Complex Grinding Machine SVG-E800 (SVG series), suitable for composite grinding of inner and outer diameters and end faces of various big cylindrical workpieces. Its mechanical structure adopts a double column type design, featuring high rigidity, high precision, high stability, and high efficiency. It is encased in aesthetically pleasing fully enclosed safety covers, and can be equipped with controllers from Fanuc, Mitsubishi, or the latest generation. With its conversational interface, operation is intuitive and easy. The grinding wheel spindle system is HSK-A100, 10000rpm, 18.5/15kw, capable of automatically changing wheel holders, with an ATC device capacity of 6 tools, and a spindle angle positioning system at 0 degrees/22.5 degrees, enabling various grinding processes with just one clamping. The workpiece spindle adopts a hydrostatic system turntable with a diameter of 800mm, maintaining axial movement accuracy <1μm. Models with turntable diameters of 600mm and 1200mm are also available. For further technical specifications, please contact the Sales Department of SIGMA CNC.

YING HAN TECHNOLOGY CO., LTD.

製品の説明 :

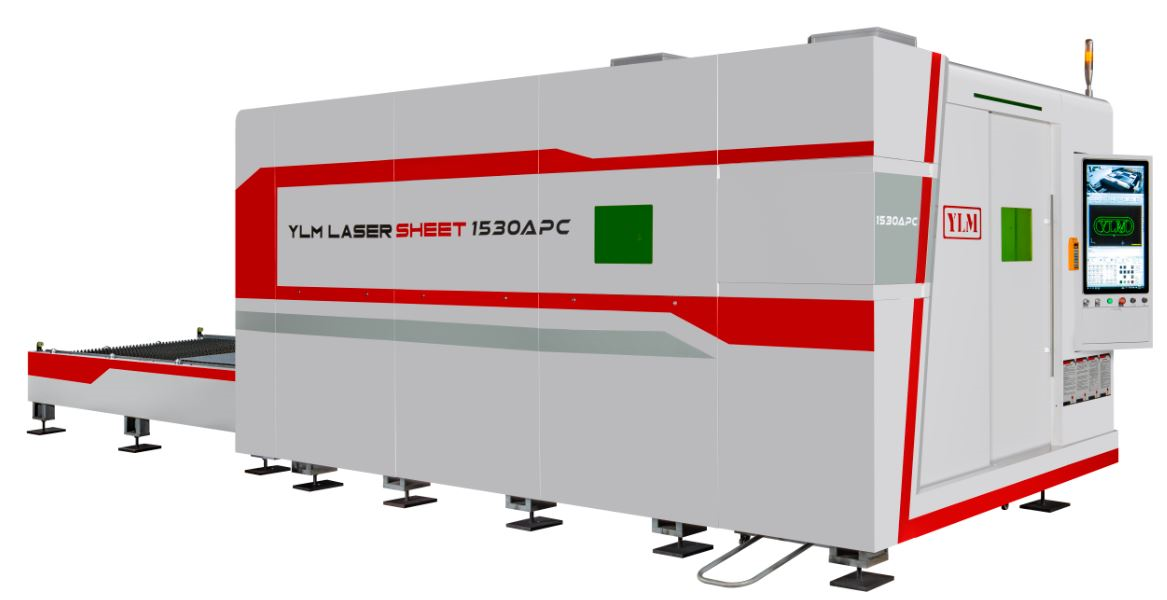

Suitable for cutting various metal sheets

■Maximum cutting thickness of metal sheet varies with the laser power.

■Upon customer request, the machine can be designed with a work piece platform as mechanism(optional). It helps to reduce work piece loading/unloading time, which in turn upgrades operation efficiency.

■Large laser power, high efficiency and high productivity.

■Equipped with an intelligent digital controller featuring humanized control, which is easy to learn and operate.

■The specially designed software allows the operator to design the graphs on characters with ease, then machining can be conducted immediately.

■Enclosed splash guard

■Fast machining, power saving, outstanding safety protection, low trouble and easy maintenance.

For cutting commonly used metal sheets such as:

■Carbon steel sheets

■Alloy steel sheets

■Galvanized steel sheets

■Stainless steel sheets