展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

SCN MACHINERY CO., LTD

製品の説明 :

180°油壓反轉合模機 - SDP series<br />

<br />

Tonnage: 50 - 600 ton<br />

Bolster Area: 1000 x 800 - 4500 x 3000 mm<br />

<br />

龍門型高強性、高精度機身設計,操作簡單的控制系統。<br />

動作精確,機台易操作,可減少勞動者的勞累,提高工作安全。<br />

適用於各類精密成型模具精修。(沖壓模、射出模、鋁壓鑄模)<br />

上模可180°完全翻轉,方便工作人員精修模具。<br />

標準附件:10"LCD觸控螢幕。<br />

符合ISO 9001:2015認證

RAISE PRECISION CO., LTD.

製品の説明 :

Our range of optical sensors comprises classic forked light barriers with red light or infrared technology. Still greater accuracy is offered by our laser light barriers, which even respond to tiny objects.

The special design with integrated air system is an optimal solution when it comes to contamination, as the air system prevents dust and dirt from collecting on the transmitter and receiver.

A further CAPTRON innovation is the product series of TCP measurement units with laser. TCP measurement units ensure a highly precise tool calibration and precise XYZ measurement in industrial robots. TCP measurement units are commonly used in robot-based automation processes in the metering and bonding technology, welding, soldering and in the food industry.

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

SY2-42 Swiss-type CNC Lathe

■ SY2-42E has Ø42mm maximum bar feeding dia. and provide the option to go with or without a guide bush to achieve optimum machining condition.

■ Main spindle tool system can install 6 radial live tools, 3 axial live tools, 6 O.D. tools, 5 I.D. tools.

■ Sub Spindle tool system can install 8 ER-20 live tools, combines with the Y2 linear axis and C2 rotating axis to perform the more complex turning and milling process.

KAO FONG MACHINERY CO., LTD.

製品の説明 :

KG series gantry five-sided machining center is able to choose to carry all kinds of automatic additional head (90゜angle milling head, universal head, extension head, speed-up extension head ... etc.) auto tool changer. Standard verticaland horizontal tool changer magazine tool with optional multi-head library for automatic head exchange. Angle head part has 5° division curved tooth with standard high precision, and are able to select 1/2.5°division or watering function at the center. KG5A series bridge crane five-axis machining center is mainly designed for the processing demand on medium and large weight workpieceparts, with world-class high-quality five-axis manufacturing technology to complete the five-axis processing, it synchronously completes vertical, horizontal and a variety of free angle of processings, which substantially increases the processing efficiency. Floor-type workbench with super load capacity, up to 2.5 tonsweight per square meter. Adopting HSK-A63 24,000 rpm high-speed spindle or the heavy cutting spindlewithHSK-A100 10,000 rpm high-torque output depends on different maching applications, which greatly improves the processing efficiency of large workpiece, and fully meets the processing needs of different industries.

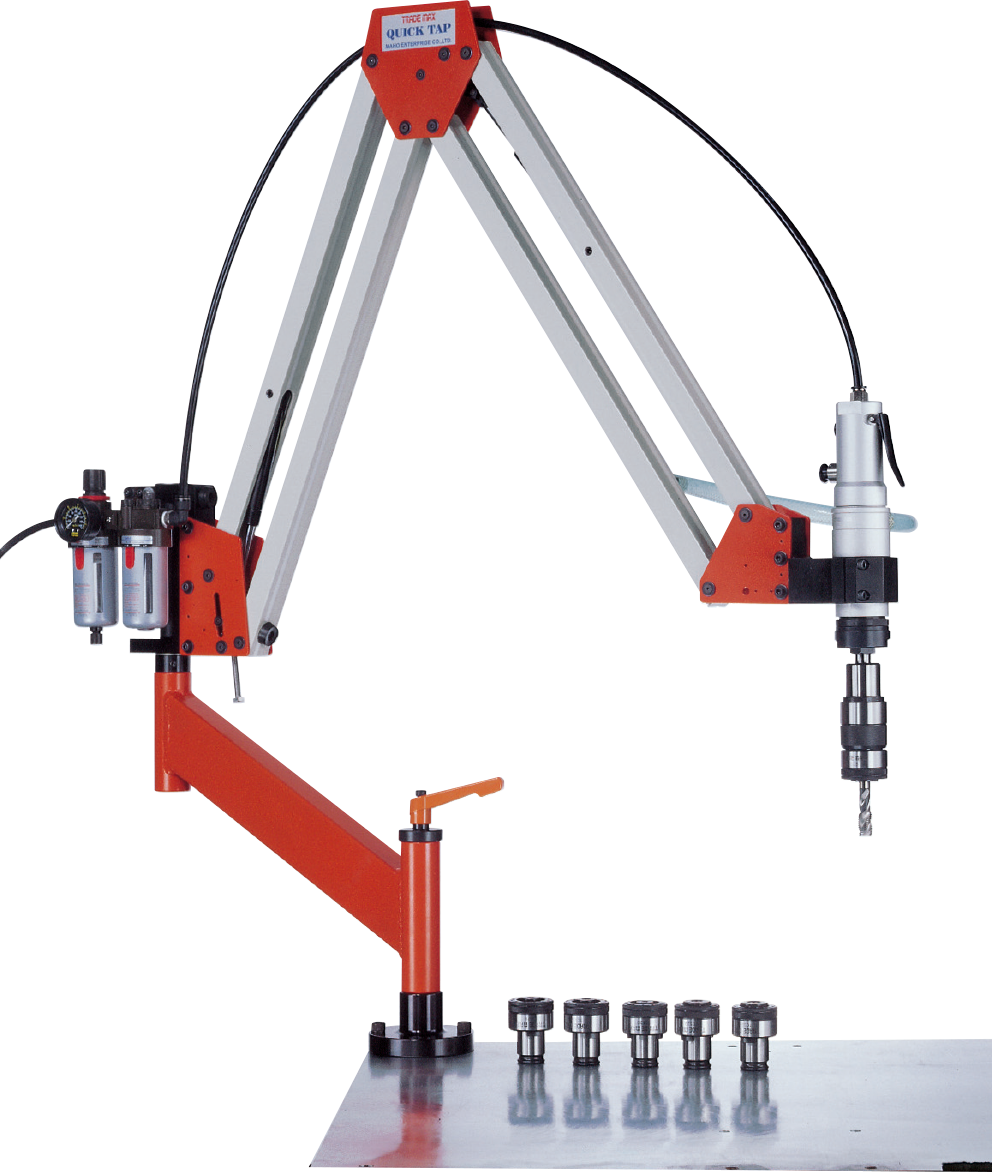

MAHO ENTERPRISE CO., LTD.

製品の説明 :

Pneumatic tapping machine is suitable for different size taps (from M2 to M27). The arm is equipped with lubricated for life bearings at all swivel points, provides weightless operation through the use of gas counter balance springs and permits the operator to bring the tap to the hole with ease.

RAISE PRECISION CO., LTD.

製品の説明 :

CAPTRON is an experienced measuring technology manufacturer for the industry and the market leader in fill level measurement in the field of dispensing technology. Capacitive CAPTRON probes accurately and reliable measure the fill levels of liquids, bulky goods, pastes, adhesives and chemically aggressive materials.

With the CAPselect system for level sensors, you are able to freely configure the probe of your choice depending on the application, container type and sensor properties. CAPTRON produces these with millimetre accuracy to ensure full flexibility.

There are two systems to choose from: Compact probes, in which the electronics and probe form a single unit. Probes with external amplifiers that are suitable for applications with high temperatures and pressures.

Thanks to their wear-free electronics combined with high-quality material such as stainless steel, Teflon and Peek, CAPTRON level sensors are reliable, robust and long-lasting.