展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

IGUS TAIWAN COMPANY LTD.

製品の説明 :

●drylin®自潤直線導軌T-直線導軌系統<br />

drylin®自潤直線導軌T型直線導軌系統特別適用於自動化及處理系統應用。 它開發的目的是為了創造在不同環境中,甚至在極端環境中的一種高性能免保養的直線導軌系統。 <br />

<br />

●drylin® N緊湊型直線導軌系統<br />

drylin® N直線導軌/線性滑軌/直線滑軌超薄導向系統具有各種寬度的超薄尺寸。與所有drylin®直線滑軌產品相同,滑塊在陽極氧化鋁剖面上免上油運轉。 所用的材質和獨特的設計使drylin® N直線導軌/線性滑軌/直線滑軌成為一個經濟有效且靈活的導向系統。<br />

<br />

●drylin® W - 幾乎無設計局限性的直線導向系統<br />

DryLin® W直線導軌/線性滑軌/直線滑軌——型材導向裝置<br />

drylin® W直線導軌/線性滑軌/直線滑軌型材導向裝置是一種經濟有效的預裝配系統。 這種設計提供了極大的設計自由度,單軌或雙軌應用還簡化了安裝。導軌材質選用硬質陽極氧化鋁,使型材導向裝置具有最佳摩擦和磨損性能。 由於不使用潤滑劑,系統耐髒污性極強,因此還非常適合清潔和衛生環境中的應用。<br />

<br />

●drylin® 自潤直線導軌/線性導軌R <br />

drylin®自潤直線導軌R由高性能耐磨聚合物材料製成,特別適用於直線技術。 尺寸均與標準滾珠軸承一致。 特別的幾何形狀確保其在極端環境中依舊適用。<br />

螺旋傳動裝置是將旋轉運動轉換成直線運動的機器元件。 drylin®直線導軌/線性滑軌螺旋傳動總是基於自<br />

潤滑的塑膠螺母,因此無需外部潤滑就可實現長期運轉。 主軸(梯形螺紋或大螺距螺紋)保持乾運轉,從而具有很多技術優點。例如,無髒污黏在潤滑劑上的情況。 因此螺旋傳動既可以用於有極端髒污<br />

積聚的環境中,也可以用於衛生領域。 不同的螺紋類型涵蓋了多種應用領域。<br />

<br />

更多資訊: https://www.igus.com.tw/

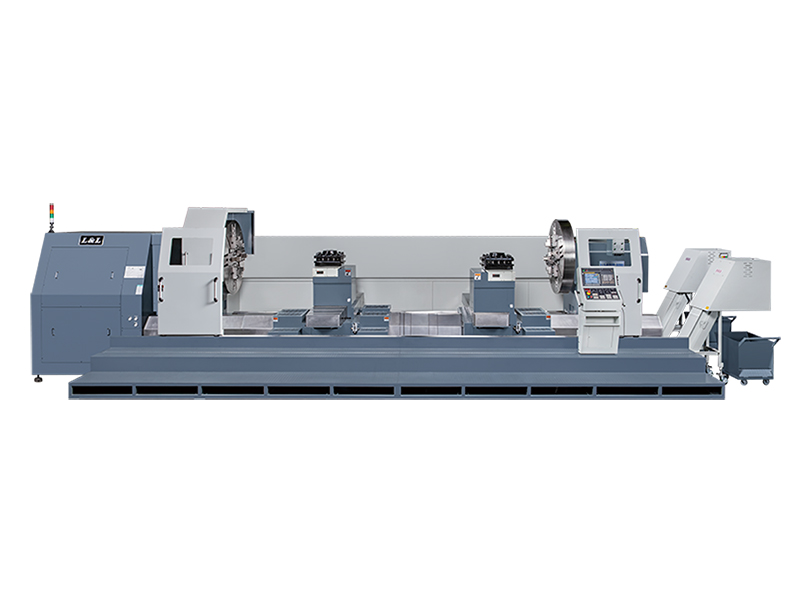

L & L MACHINERY INDUSTRY CO., LTD.

製品の説明 :

Smart heavy-duty multi-axis composite cutting machine, LLS-M, for the target industry market (oil industry, aerospace industry, steel industry and rubber and rubber industry), achieved ALL Processes In One Machine to reduce the clamping and shortening process, with precision and life management The intelligent machine, constructing the machine information management platform and man-machine management interface, integrating the computer numerical controller, the smart set-top box and the cloud product life cycle database, providing relevant data and data through artificial intelligence calculation analysis and application, reaching the machine Accuracy and life and performance improvement, and applied to the virtual reality pre-sales service system, the use of the real-life expansion after-sales service system to build a smart mechanical value service chain.

KAO FONG MACHINERY CO., LTD.

製品の説明 :

KG series gantry five-sided machining center is able to choose to carry all kinds of automatic additional head (90゜angle milling head, universal head, extension head, speed-up extension head ... etc.) auto tool changer. Standard verticaland horizontal tool changer magazine tool with optional multi-head library for automatic head exchange. Angle head part has 5° division curved tooth with standard high precision, and are able to select 1/2.5°division or watering function at the center. KG5A series bridge crane five-axis machining center is mainly designed for the processing demand on medium and large weight workpieceparts, with world-class high-quality five-axis manufacturing technology to complete the five-axis processing, it synchronously completes vertical, horizontal and a variety of free angle of processings, which substantially increases the processing efficiency. Floor-type workbench with super load capacity, up to 2.5 tonsweight per square meter. Adopting HSK-A63 24,000 rpm high-speed spindle or the heavy cutting spindlewithHSK-A100 10,000 rpm high-torque output depends on different maching applications, which greatly improves the processing efficiency of large workpiece, and fully meets the processing needs of different industries.

JASON AUTOMATION CO., LTD.

製品の説明 :

From the robust aluminum square profile, the versatile EcoShape round tubes, through to linear guides and a wide range of connection solutions: The Bosch Rexroth modular profile system currently includes more than 1,500 modular components for all areas of your production – even for ESD, clean and dry room applications. All components are finely coordinated and offer you an almost infinite number of combination possibilities when designing your working environments.

MATRIX PRECISION CO., LTD.

製品の説明 :

2080/3080 applies the FANUC controller and high speed grinding spindle, it will design the tooth profile and grinding parameters flexibly through the intelligent

conversations window software. The machinable workpieces include the standard worms

(ZK, ZI, ZN & ZA), dual-lead worms, ZC (Niemann) worms, thread plug gauges and rolling dies. The high efficiency and high-precision machining performance meet the worldwide top brand products in this field. 2080/3080 is your best choice.

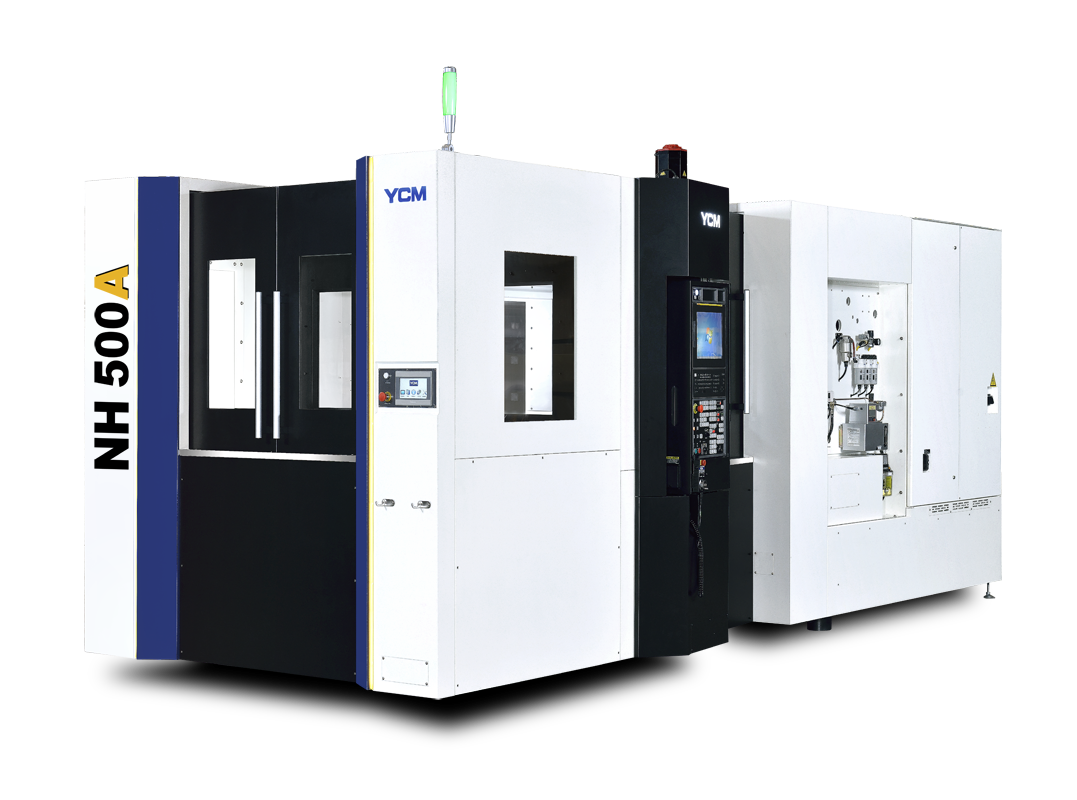

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

製品の説明 :

High rigidity and high accuracy NH500A provides the best solution for automotive, precise and mechanical parts industries.

■ High rigidity T-base foundation with rib construction

■ One-piece casting spindle headstock and dual-wall column design

■ Powerful Built-in spindle with Micro oil-air lubrication for angular ceramic ball bearings prolongs spindle life

■ High precision roller type guideways on all axes

■ High precision pallet indexing system.

ASMITH MANUFACTURING COMPANY

製品の説明 :

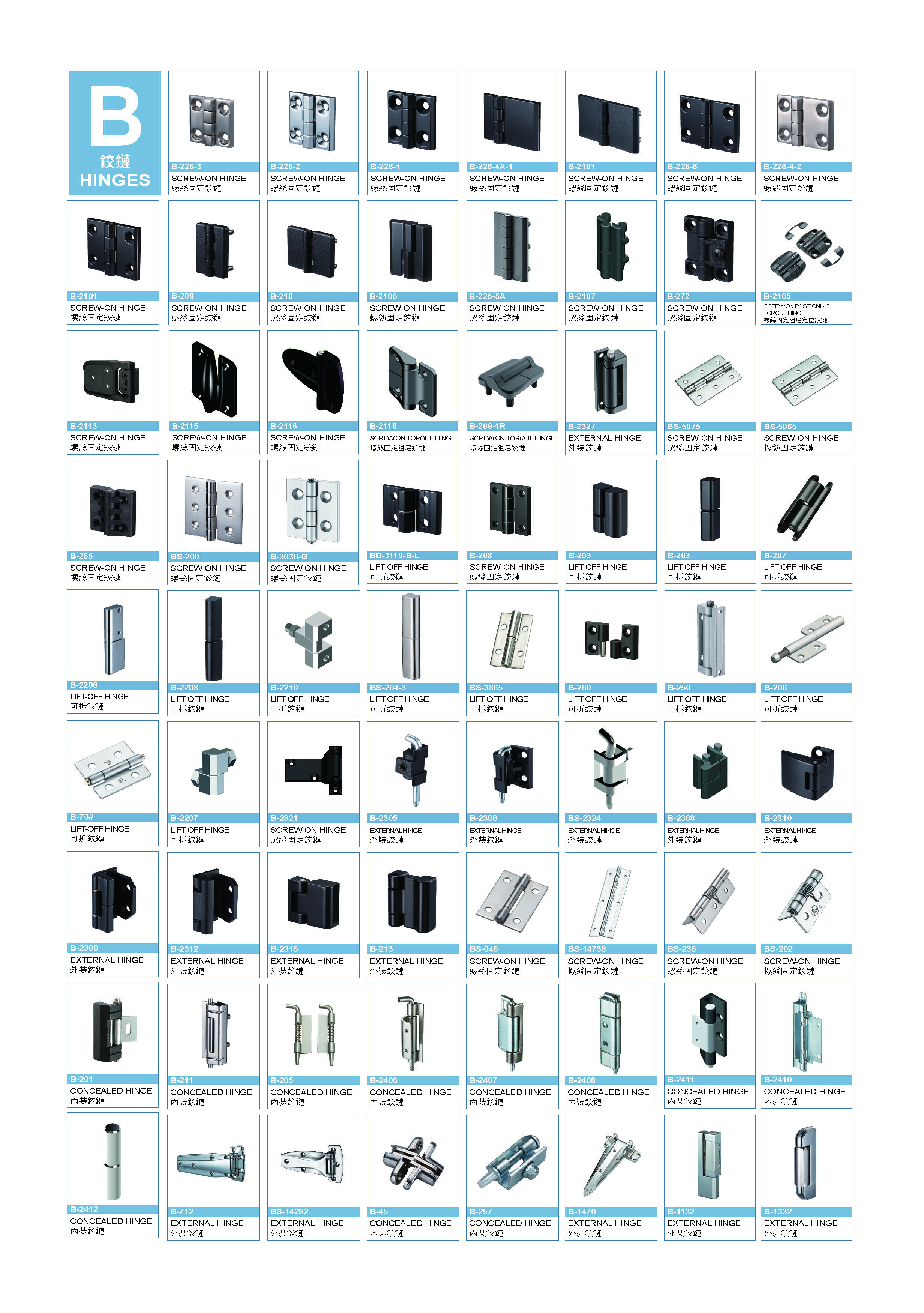

Asmith is a Taiwan professional industrial hardware manufacturer in R&D / Manufacturing / Marketing. Asmith's present facilities are certified for ISO 9001:2015 International Standard. We insist to use the original raw material from Taiwan or Japan, not to use recycling material, and produce RoHS-compliant and high-quality industrial hardware components. Product items are Hinges, Lock latches, Draw latches, Leveling feet, Casters, Lid stay holders, Door gaskets, and Digital(electronic) torque wrenches. Applicable to the semiconductor industry, ultrasonic spray machine, sheet metal, food Machinery, electronic machinery and equipment, machine tools, industrial power cabinets, rail vehicles, chassis cabinets, etc.

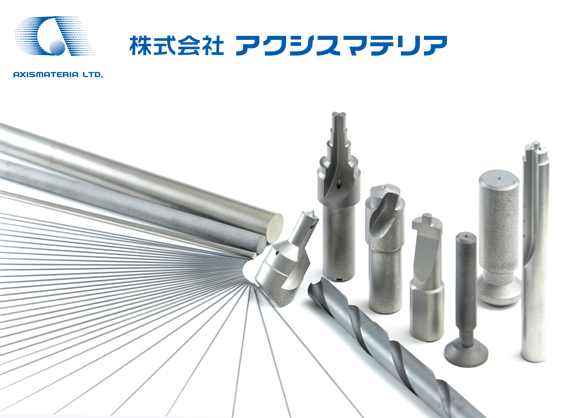

GSTC TECHNOLOGY CO., LTD.

製品の説明 :

Our portfolio covers form knurling tools, cut knurling tools, knurling wheels and marking tools in market-leading technology and quality. Our innovative power is reflected in our modern tool systems and in the continuous optimization of our production processes. The intensive dialogue with tool users from all over the world helps us to permanently improve our product concept. Modular tool systems provide the decisive extra benefit with regard to flexibility, versatility and speed.

The longstanding experience in our core competence, the profiling of knurling wheels, enables us to offer a wide standard range of high-precision knurling tools, knurling wheels and marking tools and is at the same time the perfect basis for designing, developing and producing first-class individual tool systems which are exactly customized to any special requirement.