展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

ADLEE POWERTRONIC CO., LTD.

製品の説明 :

Apply every transmission machines.

The general AC induction electric motor is designed with IEC standard. These motors fit a variety of industrial applications and it is convenient for new and used applications. Electric motor power is available from 0.25 to 20HP. The frame size is from 63 to 160.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. The structure design highlights the stability during high-speed processing.

2. The base design provides multi-angle processing and improves support strength.

3. The tool length measurement device is designed inside the ATC door to avoid contamination.

4. Equipped with high-precision DD motor rotary table.

5. Sheet-metal integration reduces assembly time.

6. Internal bevel design to avoid chip residue.

7. Multi-window device improves operation convenience.

8. Could be equipped with automation/remote monitoring to improve production efficiency.

9. Ergonomically designed to reduce operator fatigue and improve safety.

10. Small footprint improves equipment utilization.

11. High Speed, stability, and precision provide a competitive edge in precision mold and die machining.

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

FALCON MACHINE TOOLS CO., LTD.

製品の説明 :

These words describe the driving forces behind the design of our SMART-IV CNC surface grinding machines. They’re the standards required by the medical, automotive, mining, semiconductor, aerospace, injection mold making and job shop industries in order to meet current and future market needs and pave the way to factory automation.

This series is capable of producing complicated shapes for highly accurate workpieces along with finer finishes. The heavy-duty slide rails, one-piece base casting and hardened wheelhead guideways create a solid, rigid machine structure that minimizes vibration, movement and displacement.

Chevalier’s user-friendly grinding machines include our exclusive PC-based SMART iControl featuring conversational programming.

Combined with TaskLink, it allows operators to create their own programs for generating complex grinding tasks in a single cycle—without an engineering degree.

EANG LIAN CORPORATION

製品の説明 :

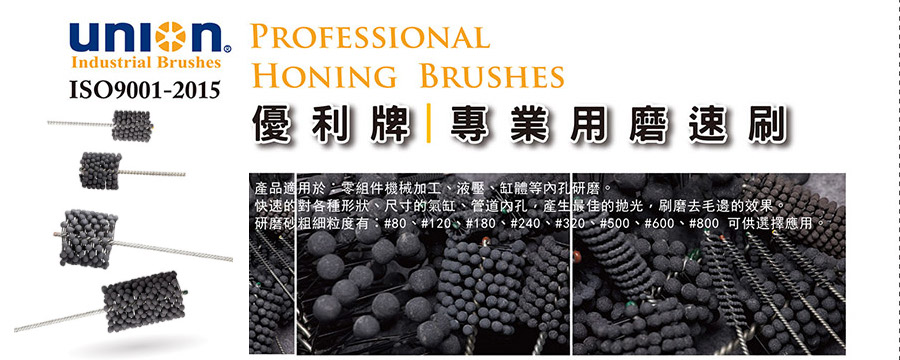

UNION Professional Honing Brushes Applications: Brake Cylinders, Hydraulics, Valve Guides Abrasive Type/Grit Size : #80、#120、#180、#240、#320、#500、#600、#800 Strong twisted wire handle for Hand or Drill use. Sizes to suit bores from 6.3 to 203mm. Ideal for surface finishing, blending and burr removal. Always use good quality honing fluid and start honing at low speed.</p>

PHB Flexible Honing BrushesF/lexible Honing Brushes

GSA TECHNOLOGY CO., LTD.

製品の説明 :

Suitable for Horizontal Machining Center,floor type boring machine。

High Accuracy,Adapting a special anti-wearing alloy of bronze/nickel double-lead worm wheel and hardened steel worm scrrew ensure long term indexing accuracy。

Table size from size 400mm to 2500mm or manufactured manufactured according to customer's designing and interface of machine Saddle。

Hydraulic Clamping,high rigid brake structure for heavy cutting。

Build-in hydraulic ports system suitable for Special Machine of Horizontal machining Center and Automobile/Motorbike Industrial。

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 機器結構為工作台固定,橫樑前後移動之高架式設計。<br />

<br />

2. 高剛性結構最適合超長超大工件之加工。加工精度極穩定。<br />

<br />

3. 超大三軸行程: X軸: 6.5~14.5米<br />

Y軸: 2.5/ 3.1/ 3.7米<br />

Z軸: 1.2米<br />

4. 整體佔地面積比一般機台節省25%以上<br />

<br />

5. 固定式工作台最大荷重能力高達10,000 kgf/m2。<br />

<br />

6. 採用FEA有限元素分析法,模擬機器變形與振動模式,以獲得最強的結構與最佳化設計。<br />

<br />

7. X,Y軸安裝機械式預壓齒輪條驅動減速機構,能獲得幾乎零背隙的線性精度。<br />

<br />

8. X,Y 軸方形硬軌都採用階梯式設計。使橫樑及主軸頭在重切削及快速進幾下能保有穩定的切削性能。<br />

<br />

9. 自動臥式換刀機構整合於原有立式換刀系統;簡化設計,具獨創性。標準頭配備立式頭及臥式頭之2個位置AAC自動執行換頭動作。更多附加頭需求時,可擴充頭庫至3-5個位置。<br />

TOP POWER MACHINERY ENTERPRISE CO.

製品の説明 :

The latest crumb collection and +1um precision filtration machine. This bottom debris recovery filter is equipped with a 1.5-inch large suction pump, which can quickly collect and dry the bottom debris and sediment in the water tank, allowing customers to clean it conveniently. This machine is equipped with a multi-functional stainless steel filter barrel that can collect coarse bottom debris. At the same time, using our patented technology, there is no need to replace the filter barrel, and it can continuously perform precision filtration up to 1um, thereby intercepting and filtering impurities and suspended particles in the water.