展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

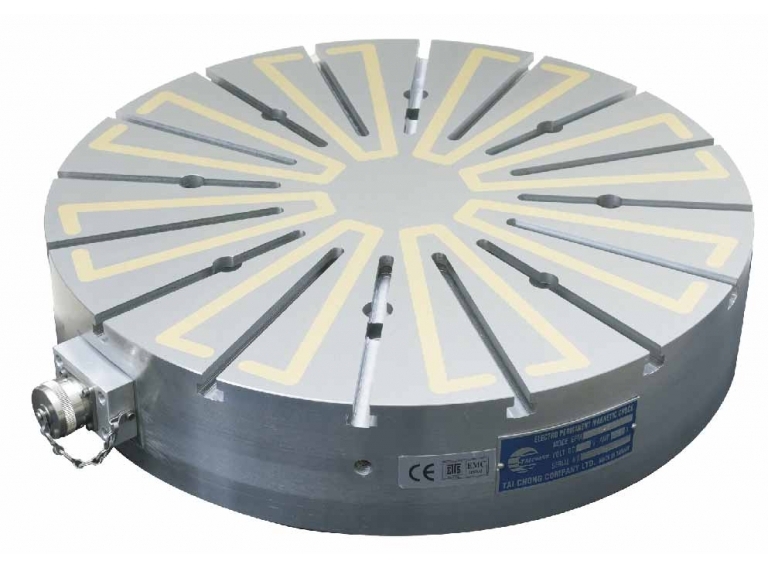

TAI CHONG CO., LTD.

製品の説明 :

用途: 車床,直立式車床,旋轉磨床等工作母機研削。<br />

特性:<br />

本體與面板一體成型加工完成。<br />

以電控操作,快速充脫磁場變換。<br />

以永久磁鐵吸著工件,沒有停電的危險性。<br />

吸磁作業面,螺栓孔可應用於模具及固定方式的變化。<br />

可配合彈性導磁塊,針對變形平面,作平面加工,大量節省調整時間,提高工作效率。<br />

結構剛性佳,配合精度穩定,適合高精度加工作業。<br />

與強力型電磁鐵比較,大幅度節省電力消耗。<br />

防水效果最確實,保證不漏水,不漏電。<br />

平均吸磁力18kgf/cm2以上。

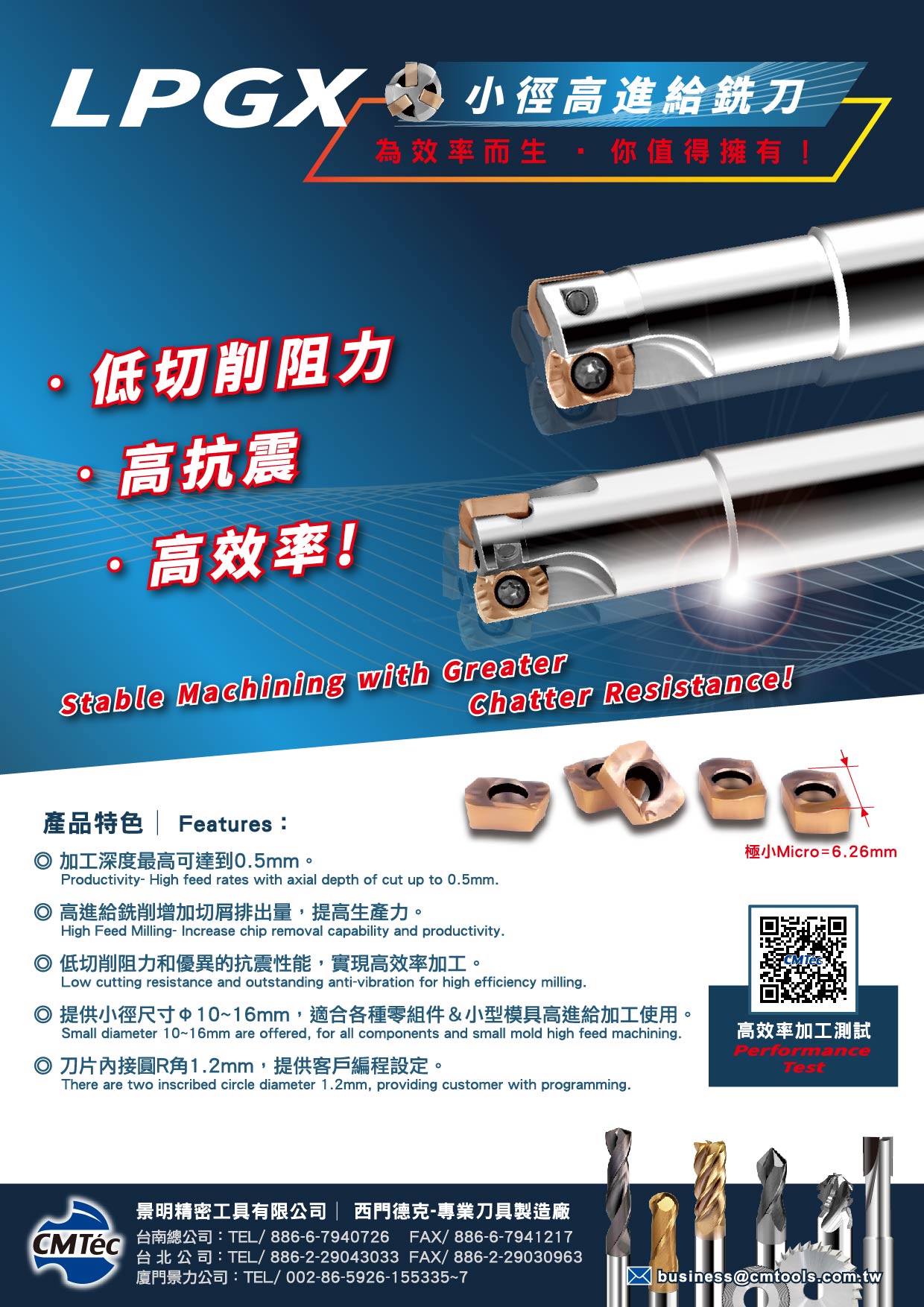

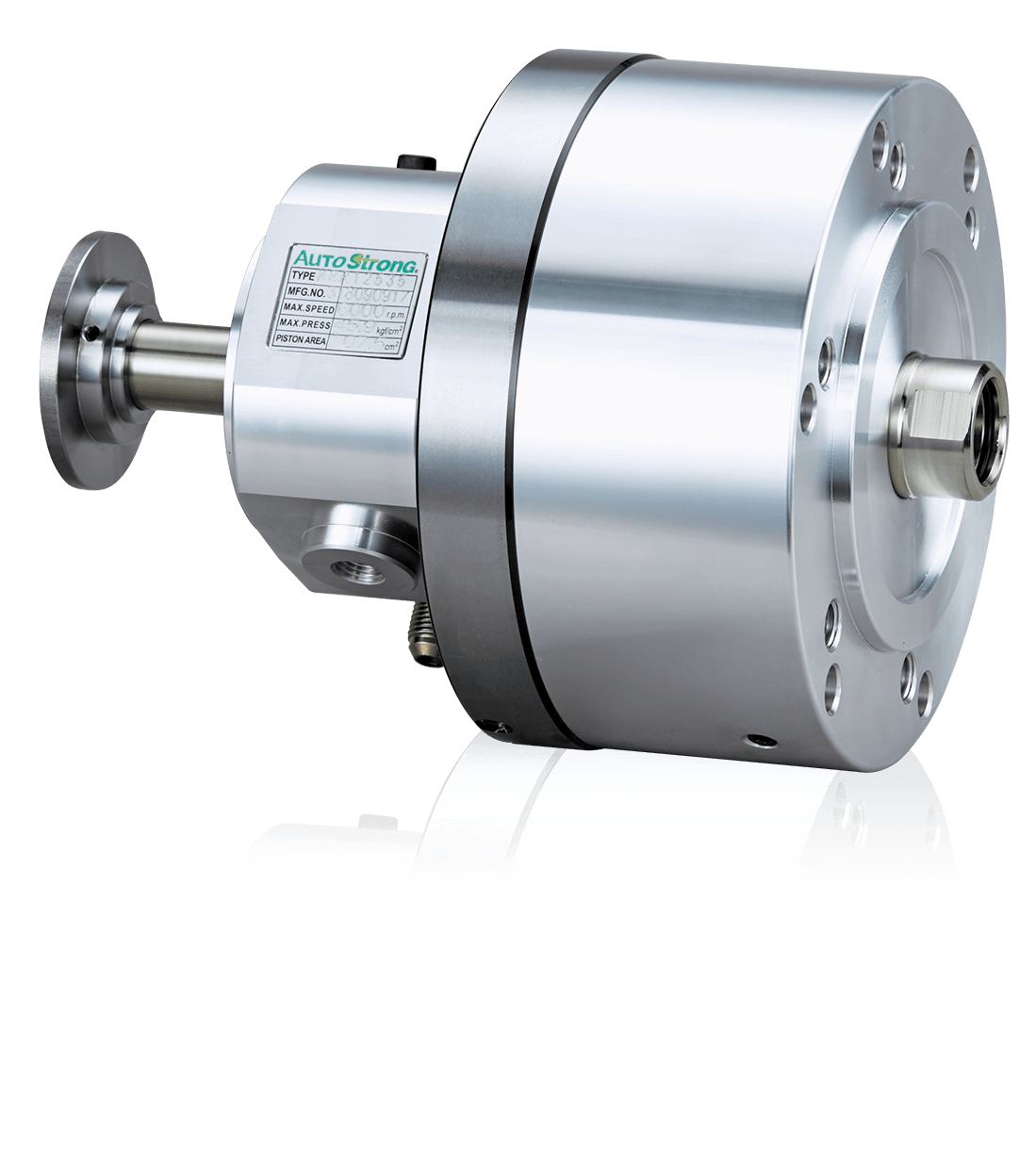

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

★ Productivity- High feed rates with axial depth of cut up to 0.5mm.

★ High Feed Milling- Increase chip removal capability and productivity.

★ Low cutting resistance and outstanding anti-vibration for high efficiency milling.

★ diameter 10~16mm are offered, for all components and small mold high feed machining.

★ There are two inscribed circle diameter 1.2mm, providing customer with programming.