展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

TAIWAN MORE-CASH VILLAGE CORP.

製品の説明 :

1.Convenient Design

X, Y axis workable professional structure enhanced high-

performance cutting accuracy.

2.Cutting Capacity

Cutting diameter: Ø3~16mm;

Cutting length of work-piece end: 15mmL/max;

3.Patented Radius cutting by Dual-motor driver

The hardened treatment steel is controlled well in virtue of

natural dissipation characteristic, cutting time is greatly

shortened as the work-piece is simultaneously rotated while

cutting.

4.Quick-Work-Changing System

The work-piece is quickly exchanged with prime quality 3-Jaw

chuck system.

5.Cooling System

Dry cooling is able to connect with various pressurized air and

vacuum cleaner achieved perfect cooling effect.

6.Cutting Disc

SD#100 for Carbide, CBN#100 for HSS

7.Optional Grinding Wheel For GS-13 GS-13

SD#100 thickness 5mm, 10mm for Carbide, CBN#100

thickness 5mm, 10mm for HSS

A.Carbide end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 55 seconds.

■ Ø 16mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 100 seconds.

B.HSS end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 60 seconds.

■ Ø 16mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 110 seconds.

YEU-LIAN ELECTRONICS CO., LTD.

製品の説明 :

The Manual Pulse Generator Engraving Handwheel by YEU-LIAN is designed for CNC operation panels, enhancing applicability through metalworking materials. It protects against dust, water, and oil, with an optical rotation, non-contact detection structure ensuring no vibration affects signal output. The encoder withstands 3 million cycles maintaining high precision, and features anti-static design, wide voltage range (DC5V to 24V), high reliability, and strong consistency. It's easy to install, suitable for various automation equipment, and CNC systems, ideal for CNC MPG pendant controllers and CNC operation panels.

JASON AUTOMATION CO., LTD.

製品の説明 :

As part of Emerson Automation Solutions, AVENTICS is one of the world’s leading product brands for pneumatic components and systems. The pneumatic engineering brand provides products and services for industrial automation, as well as the food, packaging, medical, and energy technology industries. For our pneumaitcs brand, we also develop solutions for the commercial vehicles, marine, and railway technology sectors.

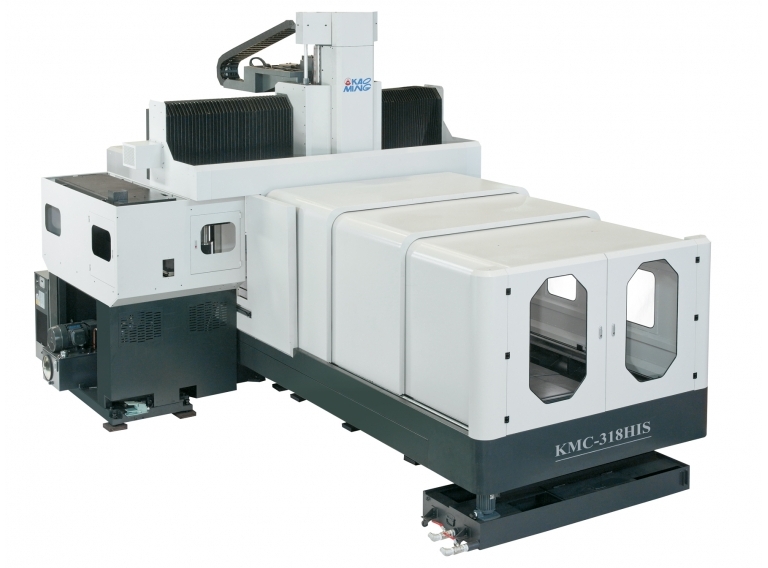

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 門寬2.1米以下,底座採用雙線軌設計;門寬2.3米以上底座採用三線軌設計,並具有硬軌之高剛性結構,Z軸行程可達850mm。<br />

<br />

2. 三軸均配備大型滾柱式線性導軌;剛性與速度兼顧。<br />

<br />

3. Y軸採用階梯式導軌設計,上軌與下軌段差225mm的特殊設計,使主軸頭不易前傾,同時分擔了部份Y軸失利於立柱的推力,使主軸頭在重切削負荷時,非常穩定;並以垂直方式偏置排列,確保最佳結構剛性。<br />

<br />

4. 主軸以直結式傳動,減少軸不對心引起的振動,提高切削性能與精度。<br />

<br />

5. 最佳主軸頭中心對稱式設計,減少熱變位影響,確保主軸精度。<br />

<br />

6. 利用有限元素分析(FEA)先進實務觀念,設計出最佳化底座立柱及橫樑等主要結構剛性。<br />

<br />

7. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

8. Z軸油壓平衡配重;在Z軸上使用兩支油壓缸抵消主軸頭重量,確保加工時的穩定性。<br />