展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

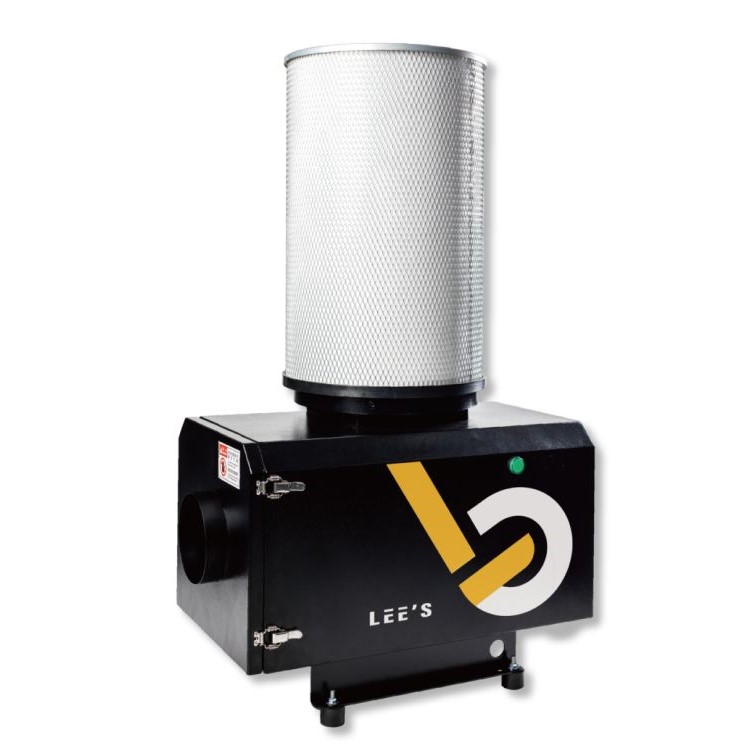

TOP POWER MACHINERY ENTERPRISE CO.

製品の説明 :

We exclusive patented technology and is committed to developing and producing products that meet global environmental protection goals. The machine is made of all metal and stainless steel materials. From the perspective of environmentally friendly equipment, it realizes the concept of net-zero and low consumables. Using the principle of physical centrifugation, a unique oil throwing device is designed, which can effectively extend the maintenance cycle and increase the filtration rate of oil smoke generated by the processing machine to more than 85%. In addition, the new generation design improves the performance of the machine with the same horsepower by 50%. Under the same efficiency, the power saving rate can be as high as 200% to 400%.

GSTC TECHNOLOGY CO., LTD.

製品の説明 :

APPLITEC is a Swiss company founded in 1987, specializing in the production of precision cutting tools, with a focus on providing high-performance solutions for small parts machining. Their tools are primarily used in CNC Swiss-type automatic lathes, specifically designed to meet the precision machining needs of industries such as medical devices, watchmaking, electronics, and aerospace.

APPLITEC’s product range includes turning tools, drills, milling cutters, and special application tools, all known for their high precision and durability. These tools help improve machining efficiency and extend tool life. The company is committed to continuous innovation, offering customized tooling solutions tailored to meet the increasingly complex demands of modern precision manufacturing. APPLITEC’s products are highly regarded in the global market, especially in applications where superior precision and reliability are critical.

STAND TOOLS ENTERPRISE CO., LTD.

製品の説明 :

◎Release magnetic sweeper has a magnetic device which enables to attract any metal items and spare parts laying on the ground without picking them up one by one

◎Pull the trigger to release magnetic force

◎Easy to use, safe and practical time saving device

◎Permanent magnet

SHARPMAX TOOL INC.

製品の説明 :

● Periodic cutting stree is effectively suppressed by

continuously changing outer teeth spacing,allowing

for chattering control.

● Excellent anti-vibration performance compatible in a

wide variety of milling for exotic alloys including

SUS,inconel,and Titanium.

● Reduces chattering for high-speed and high-feed

cutting.

● Ultra-smooth coating with significantly

improvedcoating hardness and heat resistance

improves tool live in heat resisitive ally maching.

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 機器結構為工作台固定,橫樑前後移動之高架式設計。<br />

<br />

2. 高剛性結構最適合超長超大工件之加工。加工精度極穩定。<br />

<br />

3. 超大三軸行程: X軸: 6.5~14.5米<br />

Y軸: 2.5/ 3.1/ 3.7米<br />

Z軸: 1.2米<br />

4. 整體佔地面積比一般機台節省25%以上<br />

<br />

5. 固定式工作台最大荷重能力高達10,000 kgf/m2。<br />

<br />

6. 採用FEA有限元素分析法,模擬機器變形與振動模式,以獲得最強的結構與最佳化設計。<br />

<br />

7. X,Y軸安裝機械式預壓齒輪條驅動減速機構,能獲得幾乎零背隙的線性精度。<br />

<br />

8. X,Y 軸方形硬軌都採用階梯式設計。使橫樑及主軸頭在重切削及快速進幾下能保有穩定的切削性能。<br />

<br />

9. 自動臥式換刀機構整合於原有立式換刀系統;簡化設計,具獨創性。標準頭配備立式頭及臥式頭之2個位置AAC自動執行換頭動作。更多附加頭需求時,可擴充頭庫至3-5個位置。<br />

MATECH INDUSTRIAL CO., LTD.

製品の説明 :

本數控橢圓車床係為解決汽油機與柴油機活塞的中凸變橢圓裙部之加工而設計的。

本機特性

*本數控橢圓車床採用線性伺服橢圓產生器,配合非接觸式0.0001mm超高解析度

回饋系統,具備高響應頻率、高精密度、高剛性等特點。

*由於此設備採用高效能控制核心及極短取樣時間的新一代控制器,可以獲得更快速

且精準的切銷路徑控制。

*本機部份採用全閉環式0.001mm光學尺回饋系統,近一部確保最家定位精度,並能

有效的消除熱干擾。

*新一代整合式橢圓控制器,由於不在需要資料傳輸,因此可以避免因為傳輸而導致的

雜訊干擾或資料遺失。

*編程軟體採用(看圖輸入法)編寫,操作者無須再耗費長時間學習,只要依照活塞圖面

標示的尺寸,輸入安加橢圓控制器即可,型線及相關橢圓路徑則全由控制器處理。

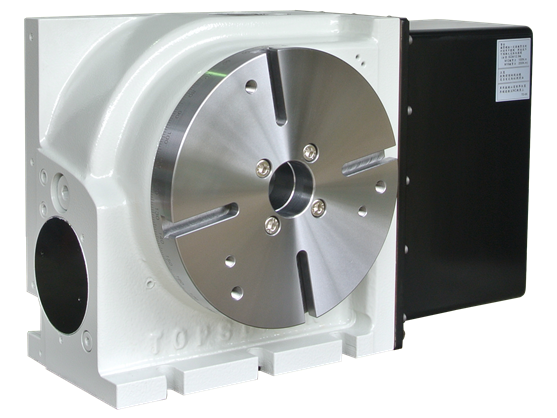

HIWIN TECHNOLOGIES CORPORATION

製品の説明 :

DATORKER® Strain Wave Gear (DT)

DATORKER, harmonic gearing system, has the characteristics of high precision, high efficiency, high torsional rigidity, and low starting torque. It is widely used in robots, automation equipment, semiconductor equipment, machine tools and other industries.

HIWIN has developed various specifications to provide customers with wide ranges of choice and be able to provide customized services to meet customer’s various design and technical requirements.