展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

QUASER MACHINE TOOLS, INC.

製品の説明 :

Flexible Manufacturing System provides a solution for

massive production or high mix low volume. Simple installation

design helps users to increase productivity in a short time.

The intelligent Automatic Pallet Change Cell has a compact

footprint design with, 6 or 8 pallet options. APC can be field

retrofitted even if the machine is settled months or years ago.

Robotic Tool Magazine Cell is a perfect match for lights out machining.

It also has a small footprint to maximize the user’s facility space.

6 manual loading pockets reduce tooling loading time efficiently.

PROTH INDUSTRIAL CO., LTD.

製品の説明 :

1.10" touch panel.

2.The Y-axis(cross) and Z-axis(vertical) are driven by serve motor.

3.Use MPG in Y-axis and Z-axis.

4.Use PLC controller.

5.Flow control regulator is used in longitudinal way for using well.

6.Auto down feed system includes auto dresser and compensation.

7.Machinable content : surface, criss-cross, plunge, form pitch.

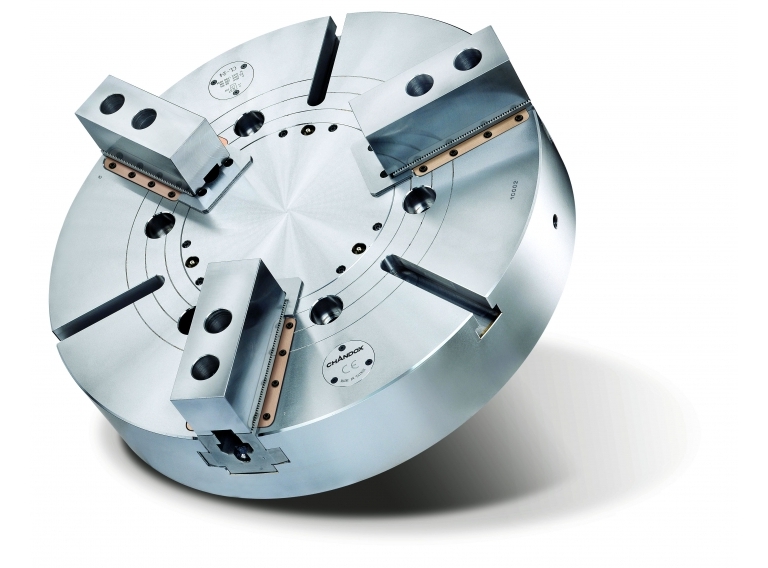

CHANDOX PRECISION INDUSTRIAL CO., LTD.

製品の説明 :

大尺寸中實夾頭,適合立式車床加工使用。

1.鋼製外殼具備穩定的機械性質以及高轉速,提昇加工穩定度與彈性。

2.特製黃銅防塵密封條,減少進入夾爪內部的切屑或雜質,降低故障機率。

3.提供多種鼻端規格的連接板方便安裝與更換。

1. Steel Chuck body have stable Mechanical Behavior and high rotating speed, it could raise your working stability and flexible machining applications.

2. Brass dust sealing which installed on the both side of slideway, can prevent the scraps into the chuck when machining, and keep the working stability.

3. We provide different flange plate for adapt with different A2 Spindle Nose size, it’s easier and more convenient for installing and changing the chuck.

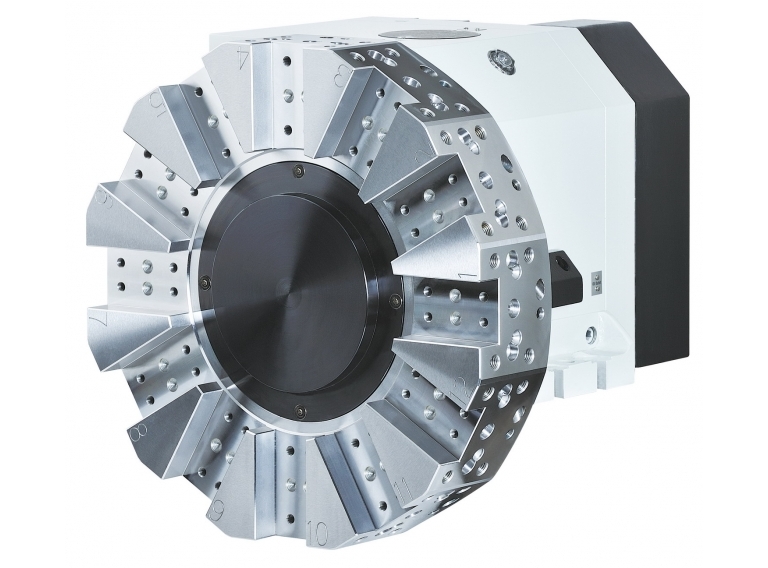

GSA TECHNOLOGY CO., LTD.

製品の説明 :

Equipped " double-cam-plate" for indexing mechanism,with compact design & high durability,suitable for heavy cutting of precision。

Driving source per hydraulic to turning tool-disc,indexing and clamping / unclamping,precisely and correctly。

Smart selection of nearby tools,controlled via proximity-detector and PLC programming,no error of tool-disc change。

Hainbuch GMBH

製品の説明 :

Increasing process stability is crucial for optimizing production. Hainbuch offers an extremely innovative solution here with the new Maxxos T212 mandrel: The Maxxos T212 is a mandrel with a pull-back effect and is therefore ideal for 5-sided machining of the workpiece on both turning and milling centers. Thanks to the hexagonal pyramid shape, the Maxxos mandrel has been developed for maximum accuracy and feed rates. The hexagonal mandrel achieves a significantly higher holding power than the round Mando mandrel and enables up to double the torque transmission and corresponding cutting rates. Hainbuch offers the Maxxos T212 mandrel in 12 sizes for the diameter range 8mm to 200mm. The Maxxos T212 mandrel has no draw bolt. It is therefore ideal for workpieces with blind holes and very short clamping lengths without any loss of clamping length.