展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

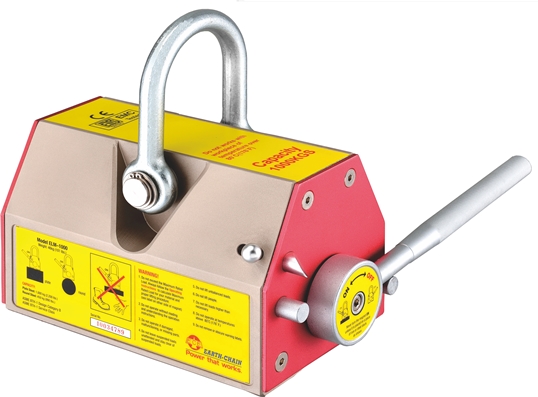

EARTH-CHAIN ENTERPRISE CO., LTD.

製品の説明 :

1.Suitable for move plate steel, block steel and round steel, such as machine parts, press molds, plastic molds and iron material .....etc.

2.Made by “Rare Earth” magnet with technology of improvement.

3.All new models with “light weight” “less dimension” and “lower price”.

4.Made by permanent magnet, require no power supply, thus eliminating hazards due to failure wiring system as electric type.

5.It features powerful magnetic force, with 3.5 times safety coefficient makes more safety in use.

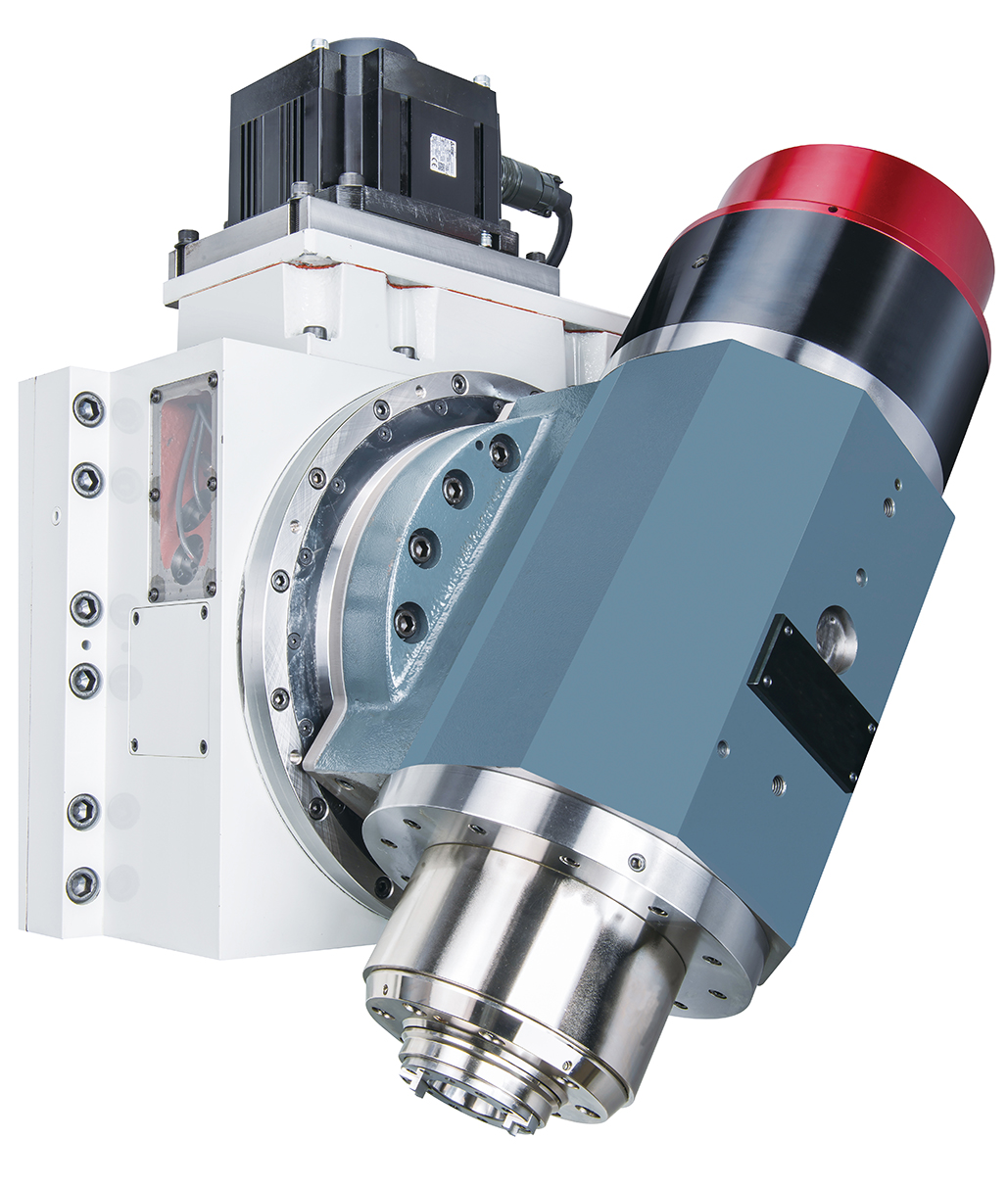

HURCO MANUFACTURING LTD., TAIWAN

製品の説明 :

UC400 series provides the cost effective solution for 5-sided parts (capable of four-axis simultaneous machining. We adopt C- frame structure with mechanical trunnion mounted directly to saddle.

However, in order to meet the requirements of high speed and high accuracy, the main casting components of the machine structure are made of high quality Meehanite casting. In addition, the box-shape structural design ensures the machine can provide the stable and high accuracy machining quality.

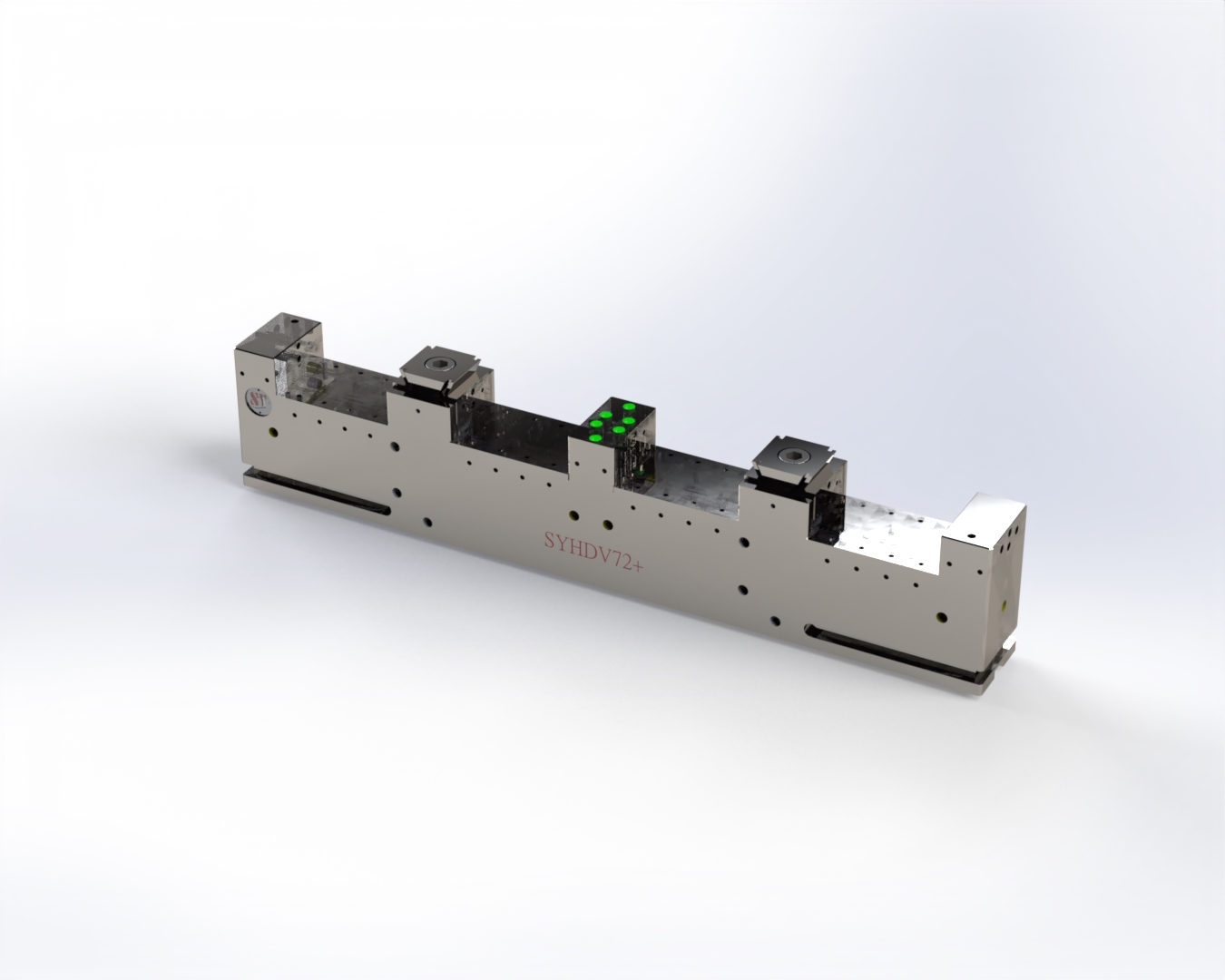

MING YANG MACHINERY CO., LTD.

製品の説明 :

The model MTY 51/65 is equipped with a dual spindle double turret and double Y axes. The machine is combined with FANUC 31i PLUS for simultaneous control on triple tool systems. The machining support two turrets for one spindle and one turret for two spindles at the same time. In other words, each process will collaborate with three tools. Mostly, the machine improves 50% efficiency.