展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

HC FENG CO., LTD.

製品の説明 :

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life

SIEMENS LTD., TAICHUNG BRANCH OFFICE

製品の説明 :

Optimizing the machining process using real-time data

Machine tool users incur unnecessary costs as a result of tool breakages, unexpected surface quality anomalies, cutting tools being replaced too early, and longer non-productive machining times. Do you know how to avoid these pitfalls and save money by leveraging your real-time cutting data?

GSTC TECHNOLOGY CO., LTD.

製品の説明 :

ECOROLL AG Werkzeugtechnik is the leading supplier of tools and machines for mechanically improving the surfaces of metal components. In close cooperation with our customers, demand-oriented tools and machines for burnishing and deep rolling as well as processing cylinders are designed, manufactured, and marketed throughout the world.

YOKE INDUSTRIAL CORP

製品の説明 :

1. Size from M8 to M90 to fulfill your demand

(M8 ※ 0.3t _ M90 ※ 40t)

2. Design Factor 4:1, Working load limit could be up to 40 tons

3. Lifting point is made by forged alloy steel, quenched and tempered

4. Suitable for all loads which swivel and tilt especially for heavy duty, material handling, mold & die industries.

5. Ball bearing inside is easier for flipping working piece and rotation.

6. Light weight, High Performance, easily for using

7. Deliver with test certification to guarantee your safety

TSYR TZUN INDUSTRIAL CO., LTD.

製品の説明 :

PRODUCT FEATURES

FM-35DL Comes with drilling force control unit for Auto-feeding:

When drill bit is worn out, this unit will drive feeding intermittently or stop feeding. Once feeding becomes difficult while making a hole, please replace a new drill bit or re-sharpen the worn out one in order to protect both drilling tool and machine body from being damaged.

FM-35DL Comes with two intermittent breaking rates for breaking chips:

Choose different feeding rates according to different drill bits and material to perform Auto-feeding operation. This device can break chips intermittently and discharge them while Auto-feeding is processing, so that chips would not roll on drill bit.

Easier to discharge chips.

The machine body is with height adjustment. It’s suitable for both lone and short annular cutters as well as general chuck which is for holding drill with straight handle.

The general chuck is applicable for holding drill which is with straight handle for drilling smaller holes(from 8-13mm).

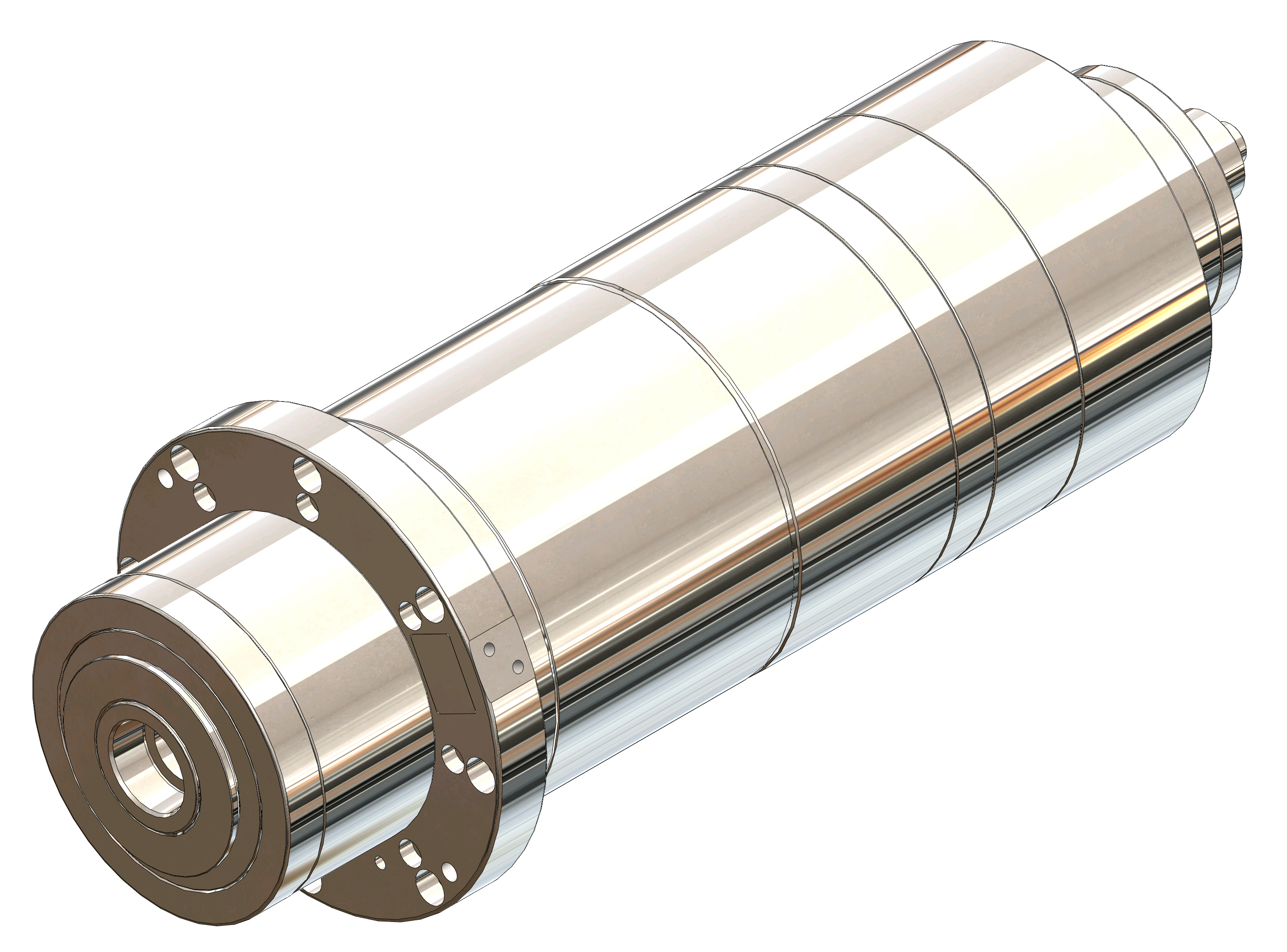

KENTURN NANO. TEC. CO., LTD.

製品の説明 :

Responds to the intelligent trends, Kenturn introduces the intelligent precision spindle for the high-speed CNC machining center. It emphasizes the thermal expansion displacement, temperature, and vibration sensing function, and can reach 30,000 rpm.

1. High speed 30,000RPM

2. Automatic Temperature Sensor

3. Thermal Expansion Sensor, Vibration Sensor

4. High dynamic rotary accuracy

JASON AUTOMATION CO., LTD.

製品の説明 :

From the robust aluminum square profile, the versatile EcoShape round tubes, through to linear guides and a wide range of connection solutions: The Bosch Rexroth modular profile system currently includes more than 1,500 modular components for all areas of your production – even for ESD, clean and dry room applications. All components are finely coordinated and offer you an almost infinite number of combination possibilities when designing your working environments.

CAPTAIN SCIENCE CORPORATION

製品の説明 :

Established in 1935 as a subsidiary of The Felters Company, originally working primarily in the shock/vibration field, UNISORB® has grown to be the leader in providing a full spectrum of advanced products and innovative engineering for the installation of a wide variety of capital equipment used in General Manufacturing, Metalworking, Testing and Verification, Printing, Power Generation, and a wide variety of other areas.

KAO FONG MACHINERY CO., LTD.

製品の説明 :

Optimized C-type structure of the proportion of gold design, machine rigidity and stability of good. Three-axis use the ball-type linear guideway. Achieving a perfect balance in the perspectives of promotion of precision and high rigidiy, the product is designed for the industry with high efficiency processing need. On the aspect of cutting chip with high efficiency, the performance is near perfect , the ultimate tool to enhance production efficiency and profit cration for investors. Mainly used in general precision machinery and 3C electronic parts, and automobile and locomotive industries, processing mold industry, aerospace, medical equipment industryand so on.