展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

CHEN SHIN (TCSM) MC CO., LTD.

製品の説明 :

Oil mist collector:

Totally made in Taiwan with TÜV CE marking.

Customisation Accessories ,Industry 4.0 Accessories and ODM/OEM Services are available.

Welcome for ODM/OEM cooperation.

We are Agent of SCOTTI in Taiwan market.

We are Agent of DUPLOMATIC in Taiwan market.

Electrical Oil Mist Collector

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

FINTEK INDUSTRY COMPANY LIMITED

製品の説明 :

Initial pinch 3-Roll plate bending machine

Affordable single pinch bending application, flexible use of small space workshop

3 rolls camber designed with hardness HRC 50-53 degrees, dealing with various material processing

Build in high quality hydraulic system with overload protection

The first choice for petty workshops or personal studio, small invest and fast get back

FAIR FRIEND ENTERPRISE CO., LTD.

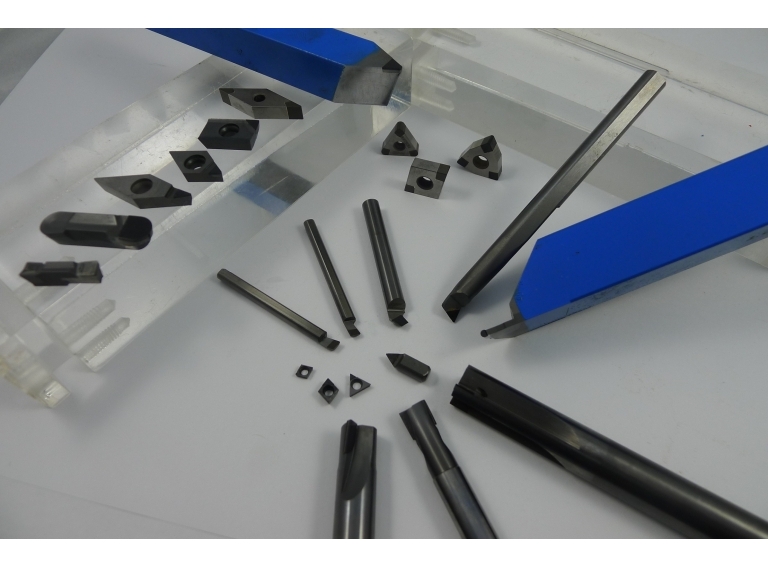

製品の説明 :

1. Improve tools life and cutting efficiency, especially ideal for particular process requirements of brittle or hard、 high-temperature superalloy and composite materials.

2. Increased precision and quality of the workpiece to achieve excellent cutting results. (smooth edge)

3. Perfected ultrasonic control technology for easy selection, automatic frequency, and power adjustment.

4. The strong chipping of chassis concentrates the chips into the path as ensures high efficiency.

5. Anti-scale cover + KEVLAR armor material, used in glasses, ceramics super hard metal processing which can preventing dust protection system effectively.。

KAO FONG MACHINERY CO., LTD.

製品の説明 :

5-axis synchronous machining of the KMU series can be used for multi-faceted processing of workpiece clamping positioning at one time or processing deep hole mold and inverted hook area.

Three-axis structure using box-type construction design, which can effectively improve the rigidity of the machine.

X / Y / Z axis with high rigidity roller type linear guideway, with high rigidity, fast moving, low wear and other characteristics, which can greatly enhance the processing dynamic precision and stability and effectively increase production efficiency.

BLUM PRODUCTION METROLOGY CO., LTD.

製品の説明 :

• Measuring speed up to 3 m/min

• Precise non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Easy pairing procedure between probe and receiver

• Use of up to 6 measuring systems with one receiver

• Extended battery life

• Precise measurement even with coolant

HIWIN TECHNOLOGIES CORPORATION

製品の説明 :

【ESG Sustainable Goal for Motion Control Components】

According to TrendForce research, the green factories will boost the global smart manufacturing market, which will reach $620 billion by 2026. As the concept of ESG sustainability has set off a wave of enthusiasm around the world, HIWIN linear motion components have also continued to focus on intelligent energy-saving innovation, providing simple, safe and modular designs to help customers upgrade from the inside out and embrace the trend of ESG energy saving!

The world’s first Intelligent 4.0 Ballscrew i4.0BS®, together with Intelligent 4.0 Guideway i4.0GW® and Intelligent Single-Axis Robot provide users to monitor health conditions of multiple machines and allow users to plan the production and pre-schedule the maintenance. The function of improving productivity and reducing carbon emission is also in line with the ESG sustainable goal.

-i4.0BS® multi-function sensors design with algorithm, effectively monitor the status of the Ballscrew. The users can monitor machines' conditions anytime.

-i4.0GW® sensor can be mounted on the block according to customers' demand. The system is fully compatible with i4.0BS®.

-The intelligent single-axis robot iSR has a modular design to meet the users' needs in various fields.