展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

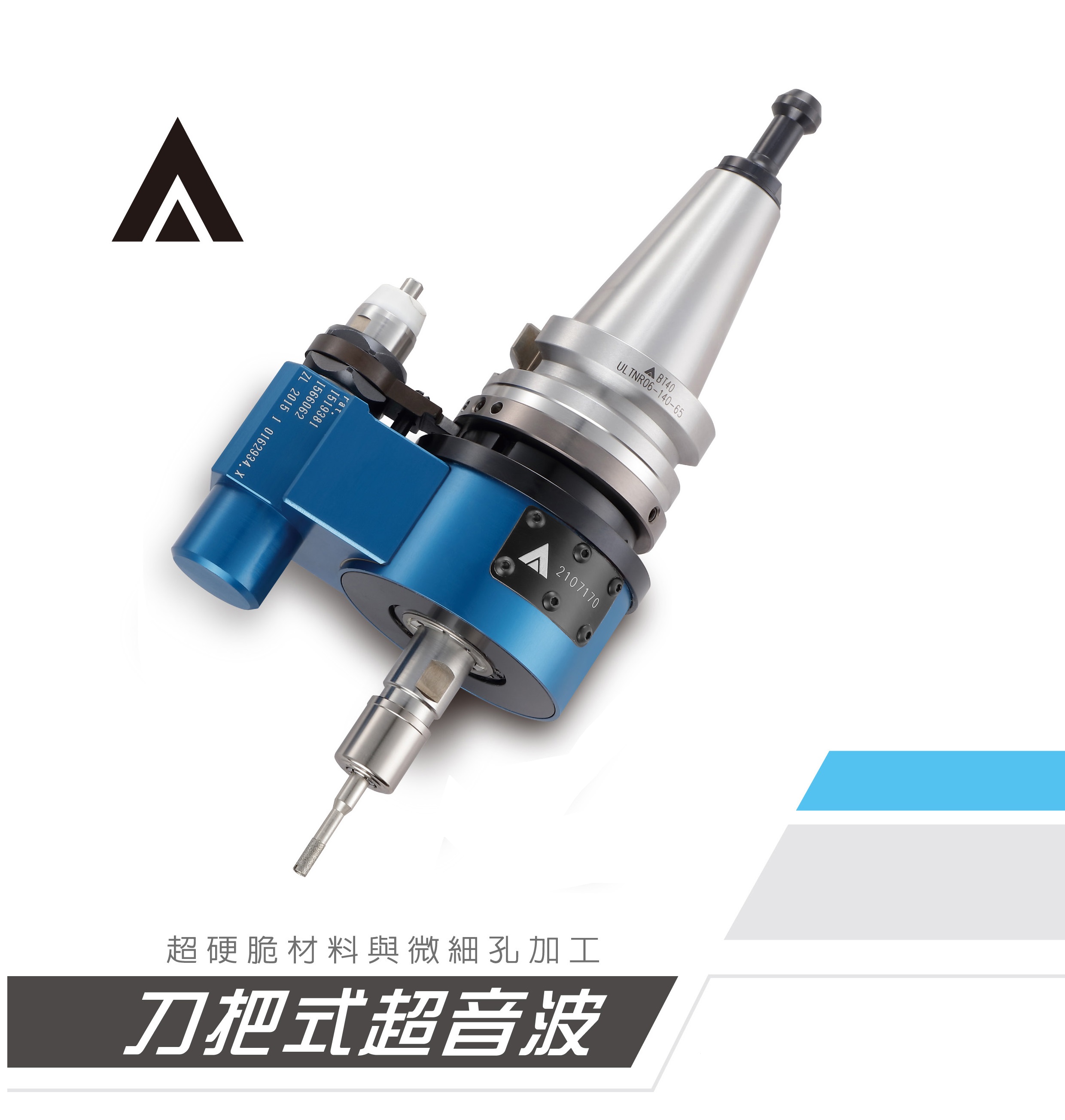

ACROW MACHINERY MFG. CO., LTD.

製品の説明 :

For Hard brittle material and micro holing drilling / Toolholder support for coolant function /

Clamping accuracy under 5 micro with the spring collets/ No need for special machine /

Easy to operate and install /

Reducing cutting resistance /

Improve surface roughness

Taiwan Laser Application Development Association (TLADA)

製品の説明 :

展覽名稱; 2026 TSMLA台灣鈑金.雷射應用展。

展覽日期:115年9月18日(五)-9月21 (一),計四天。

展覽地點:臺中國際會展中心-407台中市西屯區黎明路三段1000號

藉機械鈑金國際展貿活動,能讓同業砥礪吸引國外客戶, 以台灣雷射鈑金發展協會主辦推廣,引領未來的商機,更連結產業人士探討鈑金的新契機。

台灣機械鈑金業有近三千家的工廠,服務於各行各業,

同行齊聚,同台效應,可以交流技術擴展生意打開國際市場。

亞洲少見~台灣唯一專業的國際雷射鈑金應用之主題展, 敬邀請國內外知名專業人士參與,為台灣雷射鈑金相關產業帶來最佳的投資效益與採購商機, 並促成文化、美食、觀光、供應鏈的循環商機。

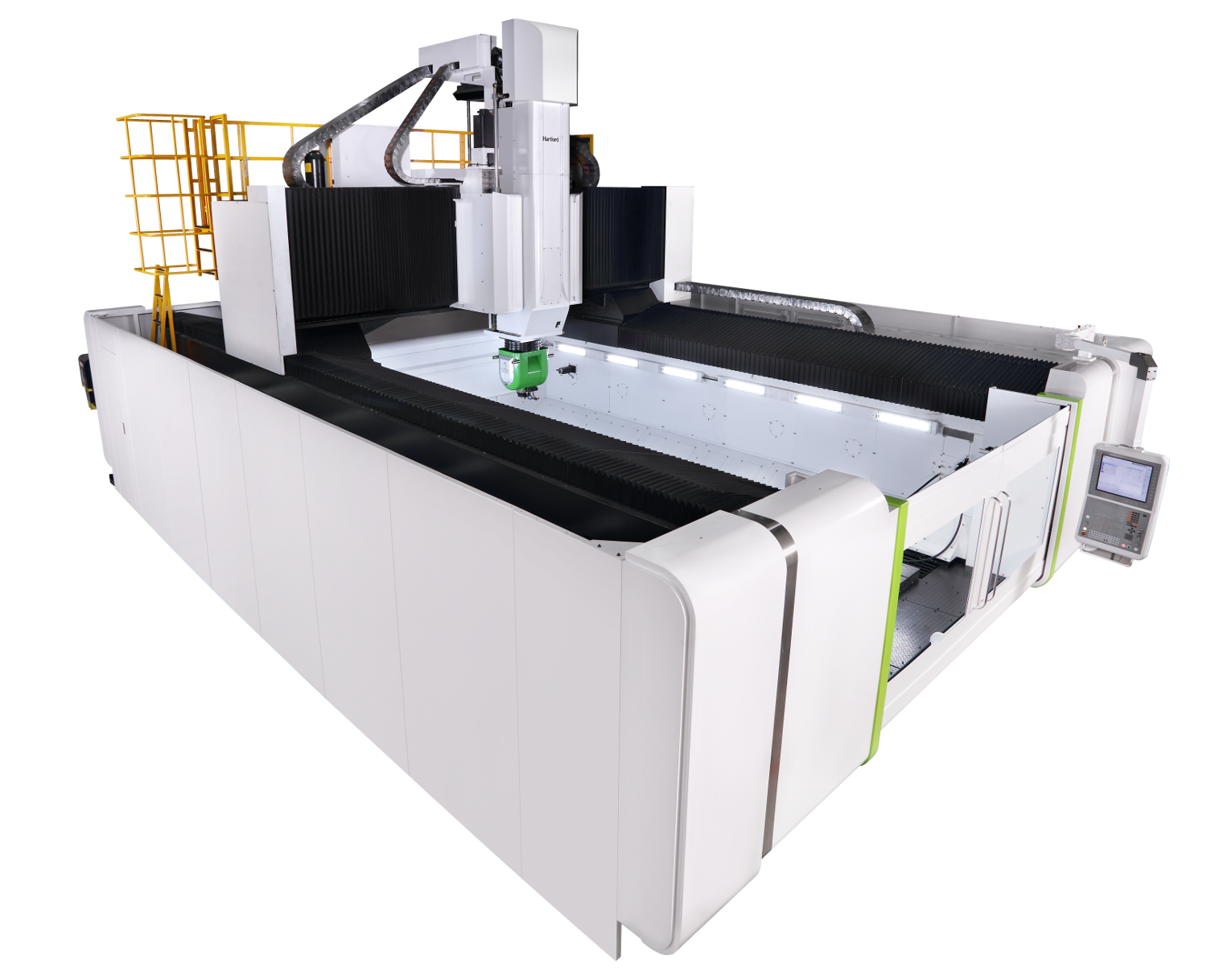

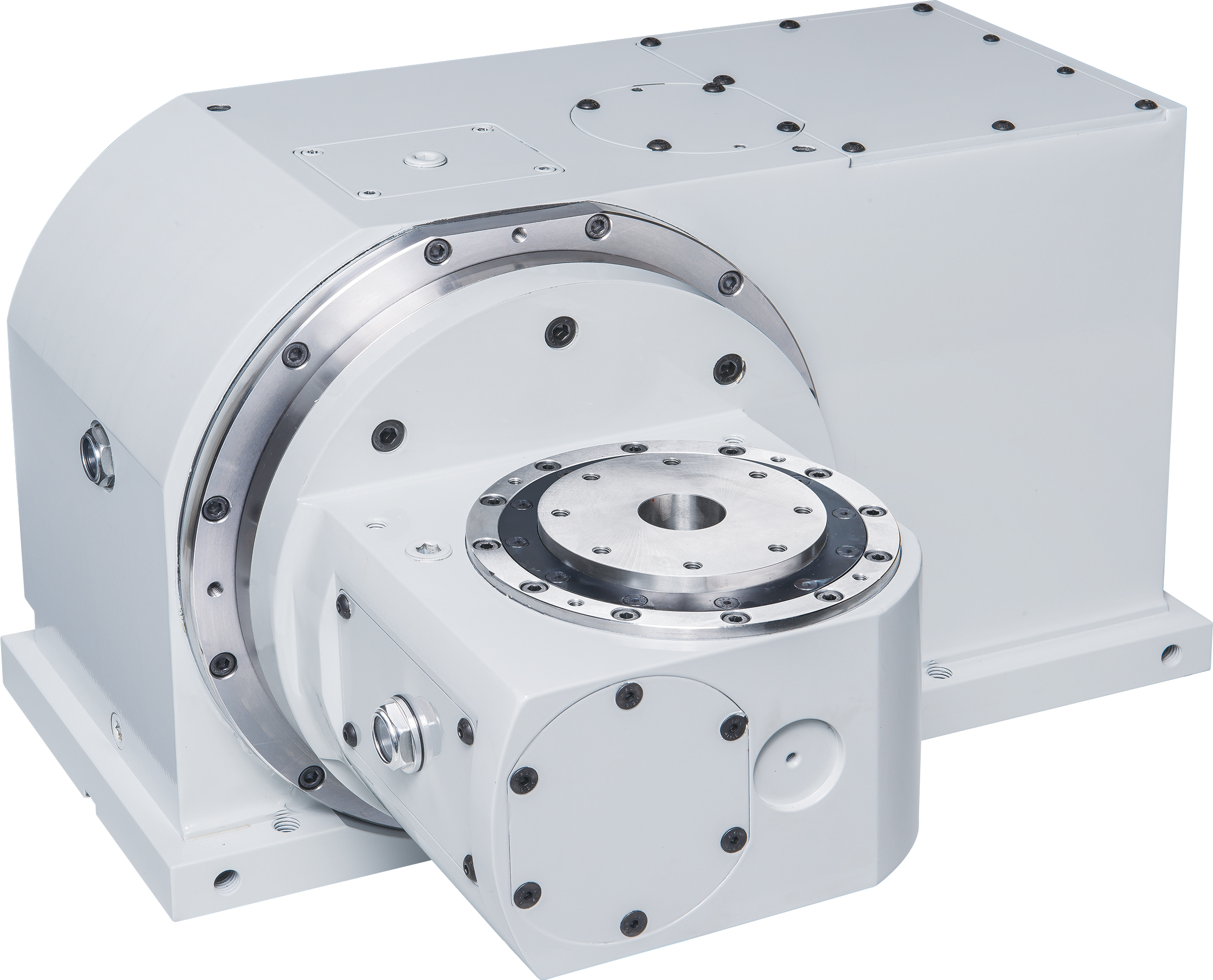

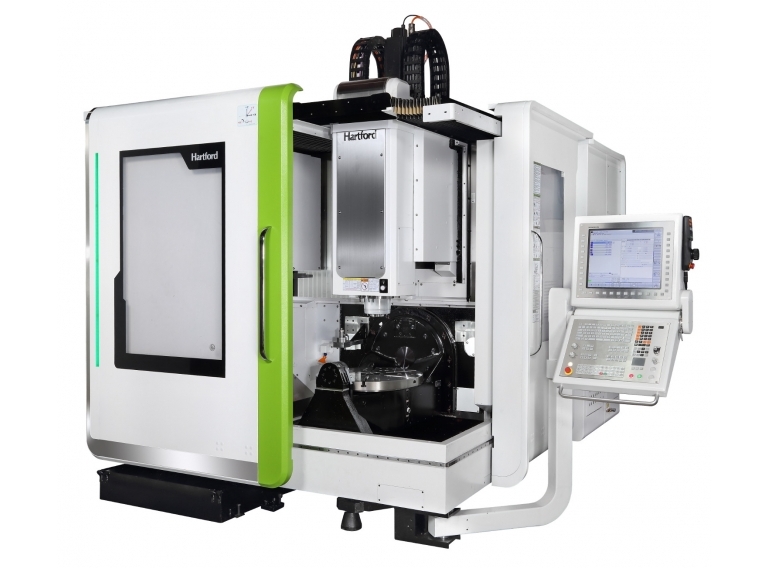

HYDEX MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

The roller cam consists of an input cam shaft and a roller turret.

The roller cam is designed with rolling contact, featuring high rigidity, high speed, and outstanding durability.

Engagement between the roller and cam are preloaded to fully eliminate backlash that enables the roller and cam to exhibit their ultra-high precision feature.

Besides, with rolling contact to transmit kinetic energy, energy consumption during drive can be dramatically reduced. This enables the roller cam to achieve over 90% of transmission efficiency.