展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

CAPTAIN SCIENCE CORPORATION

製品の説明 :

The Rotoclear C2 is a high-durability camera system designed for installation inside machine tools.

Featuring a self-cleaning lens and 4K high-resolution recording, it delivers clear, detailed views even under challenging conditions with chips, coolant, and high pressure.

It can be mounted on the top (top view), side (side view), or directly on the spindle head (tool view), providing completely new visual perspectives of the machining process.

With support for HDMI, USB, Ethernet, and RTSP/TCP-IP interfaces, the system enables real-time image capture, storage, and sharing — making it an ideal tool for process monitoring, image analysis, and smart manufacturing.

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

* Processing Method|Cutting Tools

* Applications|Die and Mold

* Customized tool design, lower cutting resistance and torque and better lifetime compared to conventional tools. Reduces the times of tool changes; Suitable for production-related molds.

* Processing Material | NAK80, SKD61, STAVAX, DC53, ELMAX, PD613, HSS, DRM, YXR3, SKHHAP

Graphite, aluminum alloy ADC12, carbon fiber reinforced plastic CFRP, glass fiber GFRP, chemical nickel, copper, oxygen-free copper, various plastic materials PU, etc.

MANFORD MACHINERY CO., LTD.

製品の説明 :

CNC Vertical Lathe

●The first spindle has C axis function, allowing the machine to perform turning milling complex operations. The second spindle accommodates fixed seat tool and live tool.

●The column is a symmetrical box type high rigidity structure.

●With the use of a high precision gearbox on CF axis for high positioning accuracy combined.

●Box ways on X/Z axis.

●12 positions armless type tool disk.

●Two-step speed change for table rotation.

HC FENG CO., LTD.

製品の説明 :

The combination of centrifugal device and magnetic separator is perfect for processing water-and oil-based cutting fluids and sludge containing magnetic dusts and shavings. The shaving removal is quick and effective, which saves a lot of time waiting and minimizes the costs to replace consumables.

7-LEADERS CORP.

製品の説明 :

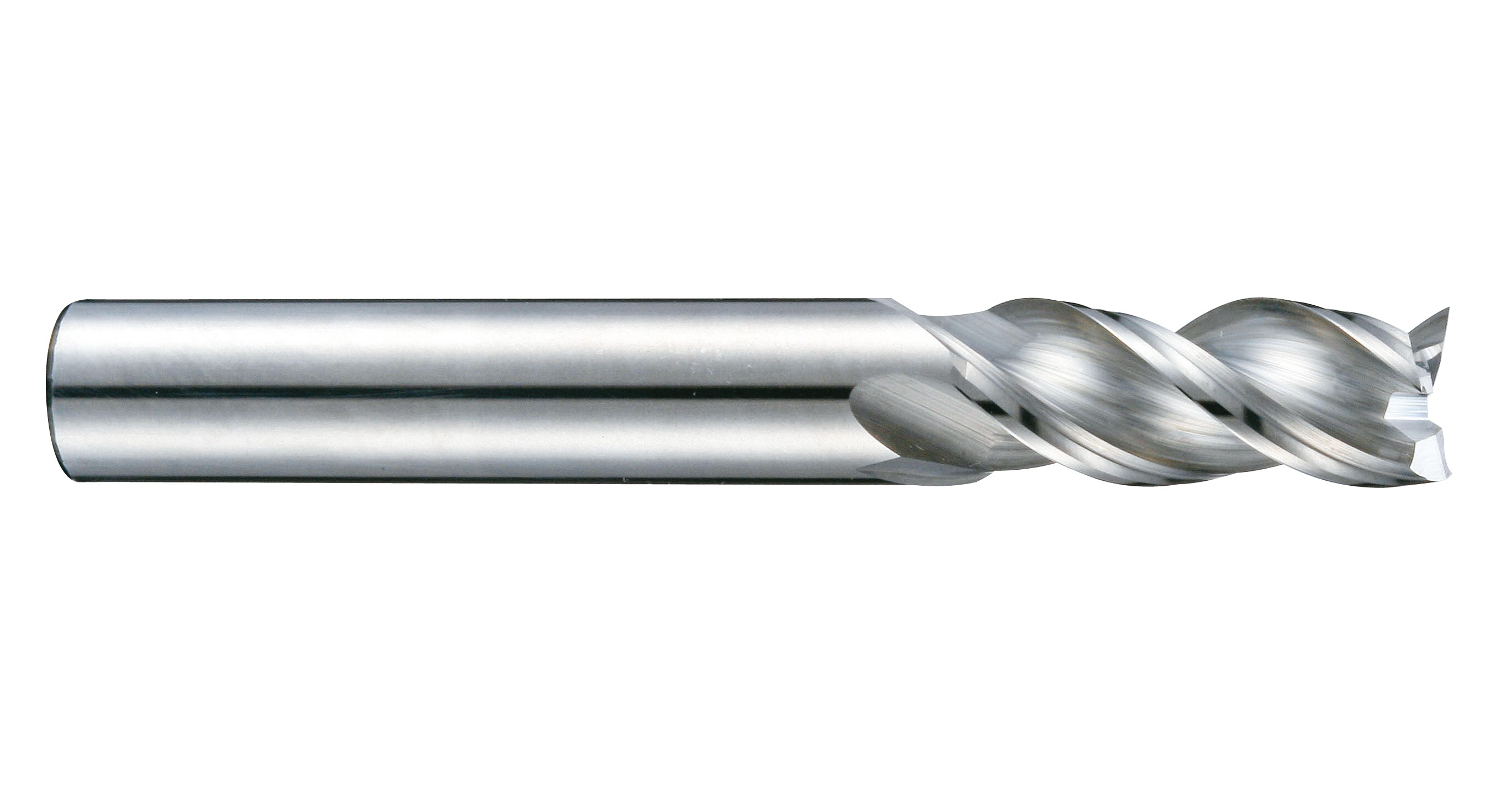

End Mills for Aluminium- 3 Flutes

Design with sharp cutting edge, high removal cutting geometry, and fine grinding smooth surface to prevent sticking problem.

Higher finishing of cutting edge to have better surface roughness after processing.

Application for roughing and finishing in various Aluminium.

JASON AUTOMATION CO., LTD.

製品の説明 :

CytroPac - The compact revolution for hydraulic power units: completely equipped and integrated.

Rexroth has started the hydraulic power unit revolution. Lack of installation space is no longer a reason to go without hydraulic power: The new CytroPac power unit provides maximum power in the smallest space with everything you need for fast installation – including an economical Sytronix drive, completely wired frequency converter and Industry 4.0 compatibility. With powerful 4 KW and pressure of 240 bar in 50 percent less installation space. Furthermore, CytroPac also complies with the EU Ecodesign Directive 2009/125/EC. Simply connect power, fluid and interface and go. A small revolution!

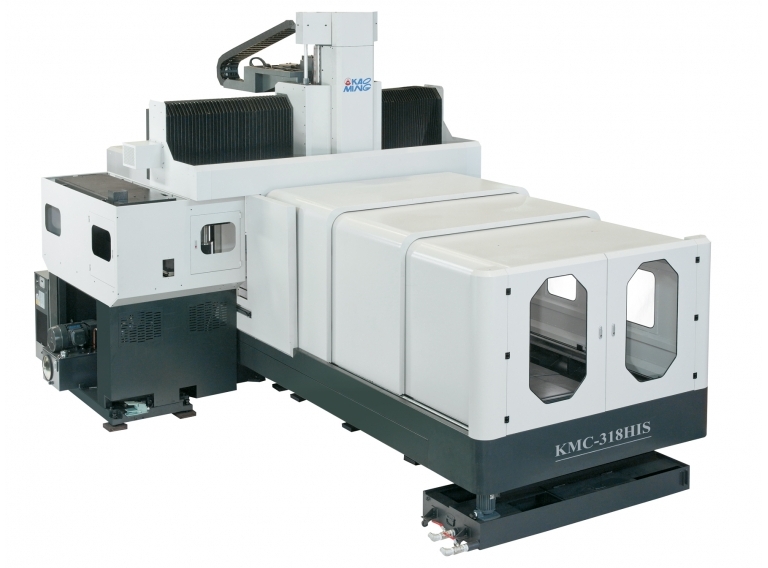

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 門寬2.1米以下,底座採用雙線軌設計;門寬2.3米以上底座採用三線軌設計,並具有硬軌之高剛性結構,Z軸行程可達850mm。<br />

<br />

2. 三軸均配備大型滾柱式線性導軌;剛性與速度兼顧。<br />

<br />

3. Y軸採用階梯式導軌設計,上軌與下軌段差225mm的特殊設計,使主軸頭不易前傾,同時分擔了部份Y軸失利於立柱的推力,使主軸頭在重切削負荷時,非常穩定;並以垂直方式偏置排列,確保最佳結構剛性。<br />

<br />

4. 主軸以直結式傳動,減少軸不對心引起的振動,提高切削性能與精度。<br />

<br />

5. 最佳主軸頭中心對稱式設計,減少熱變位影響,確保主軸精度。<br />

<br />

6. 利用有限元素分析(FEA)先進實務觀念,設計出最佳化底座立柱及橫樑等主要結構剛性。<br />

<br />

7. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

8. Z軸油壓平衡配重;在Z軸上使用兩支油壓缸抵消主軸頭重量,確保加工時的穩定性。<br />

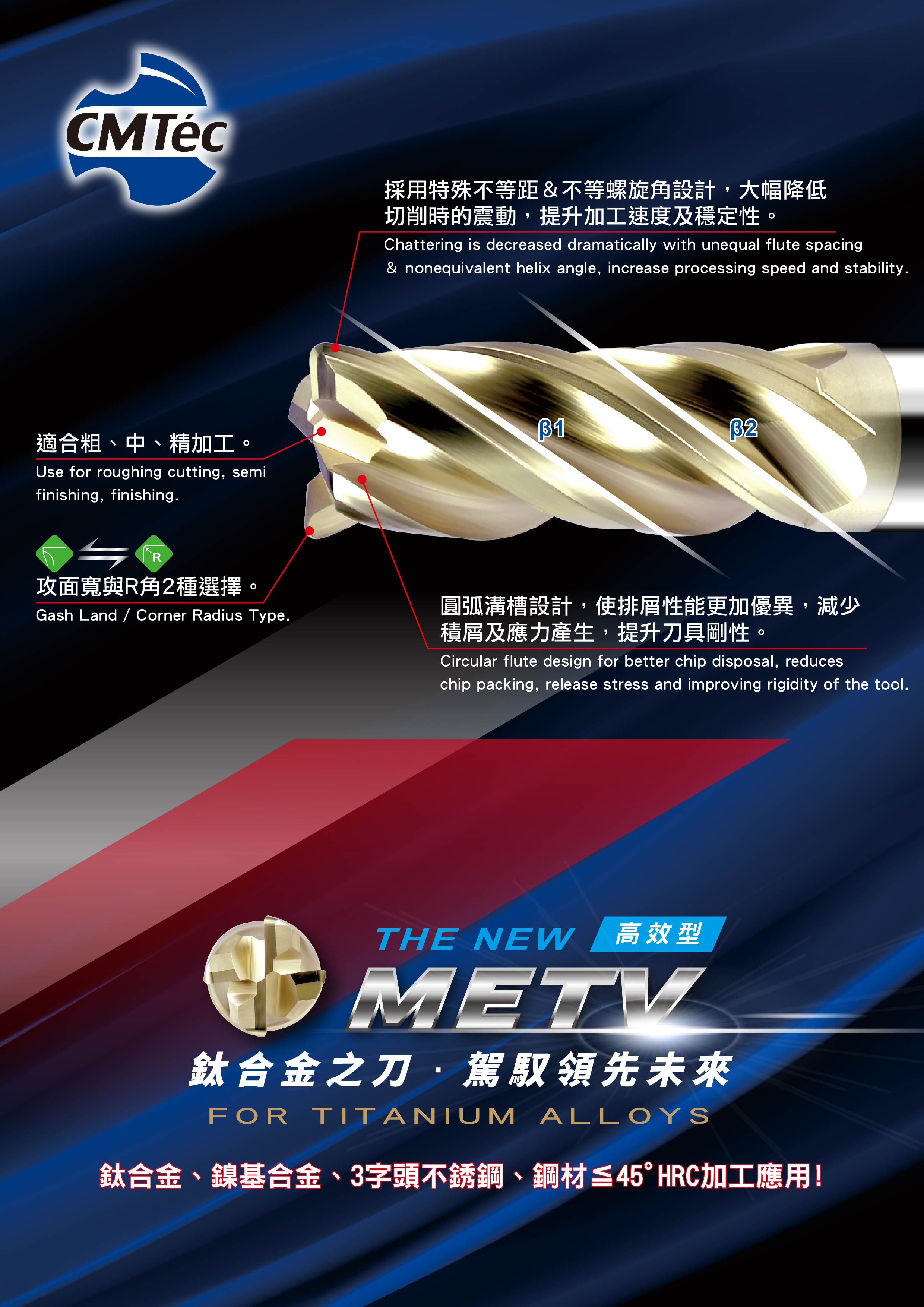

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

★ For titanium alloy, stainless steel and alloy steel(≦45°HRC) machining.

★ Chattering is decreased dramatically with unequal flute spacing & nonequivalent helix angle, increase processing speed and stability.

★ Circular flute design for better chip disposal, reduces chip packing, release stress and improving rigidity of the tool.

★ Use for roughing cutting, semi finishing, finishing.