展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.

YI CHANG MACHINERY CO., LTD.

製品の説明 :

This model is a Customized Machine that integrates a cam indexer. It connects a drilling machine and a tapping machine, achieving a one-time completion of drilling and tapping.

The machine's uniqueness lies in its advanced pneumatic clamping automatic feeding system, allowing operators to easily complete tasks and reducing operational burden.

Not only does this enhance work efficiency, but it also makes work precision easier to control.

In the pursuit of efficiency in modern manufacturing, our machine ensures operational simplicity, allowing you to focus more on the precise adjustments of your workpieces.

This video demonstrates how it achieves a one-time completion of drilling and tapping, providing higher work precision.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

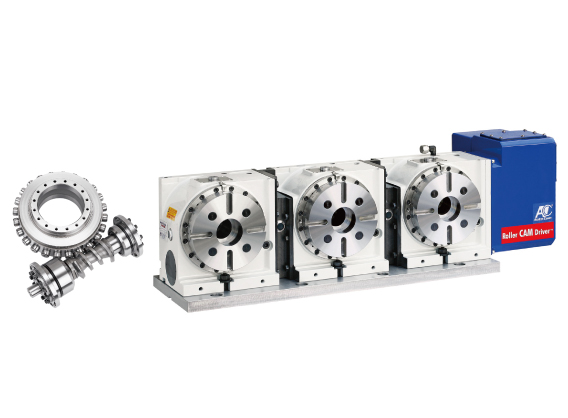

GSA TECHNOLOGY CO., LTD.

製品の説明 :

Suitable for Horizontal Machining Center,floor type boring machine。

High Accuracy,Adapting a special anti-wearing alloy of bronze/nickel double-lead worm wheel and hardened steel worm scrrew ensure long term indexing accuracy。

Table size from size 400mm to 2500mm or manufactured manufactured according to customer's designing and interface of machine Saddle。

Hydraulic Clamping,high rigid brake structure for heavy cutting。

Build-in hydraulic ports system suitable for Special Machine of Horizontal machining Center and Automobile/Motorbike Industrial。

TAIWAN MORE-CASH VILLAGE CORP.

製品の説明 :

For 2mm-13mm Twist Drill Re-sharpening , Angle 90°-140°

For 3mm-12mm End Mill Re-sharpening

Twist Drill:

1. Precise Grinding Results , Precision Assurance within 0.02mm

2. Easy to Operate , grinding a drill within 10 seconds.

End Mill

1. Adjustable Cutting Face Angle and Width

2. Easy to Operate , grinding a End Mill within 60 seconds.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Diamond Dust Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

Portable Design with only weight 14.2 kgs.

ASMITH MANUFACTURING COMPANY

製品の説明 :

Spring Loaded Draw Latch |The proposed load of 22~50 kgf.

Both sides spring design with compression function.

Standard Lock-hole can using with lock. Suitable for vibration equipment.

Smooth surface, excellent brushed finish appearance, in accordance with RoHS.

The draw latch is including the horizontal keeper [CS(T)-0120-2 or CS(T)0130-2], if you need another type keeper then you can reference the below "Accessories".

➤Material: SUS304(Stainless steel)-vibration ground and brushed finish, SPCC(cold-rolled steel)-zinc plated

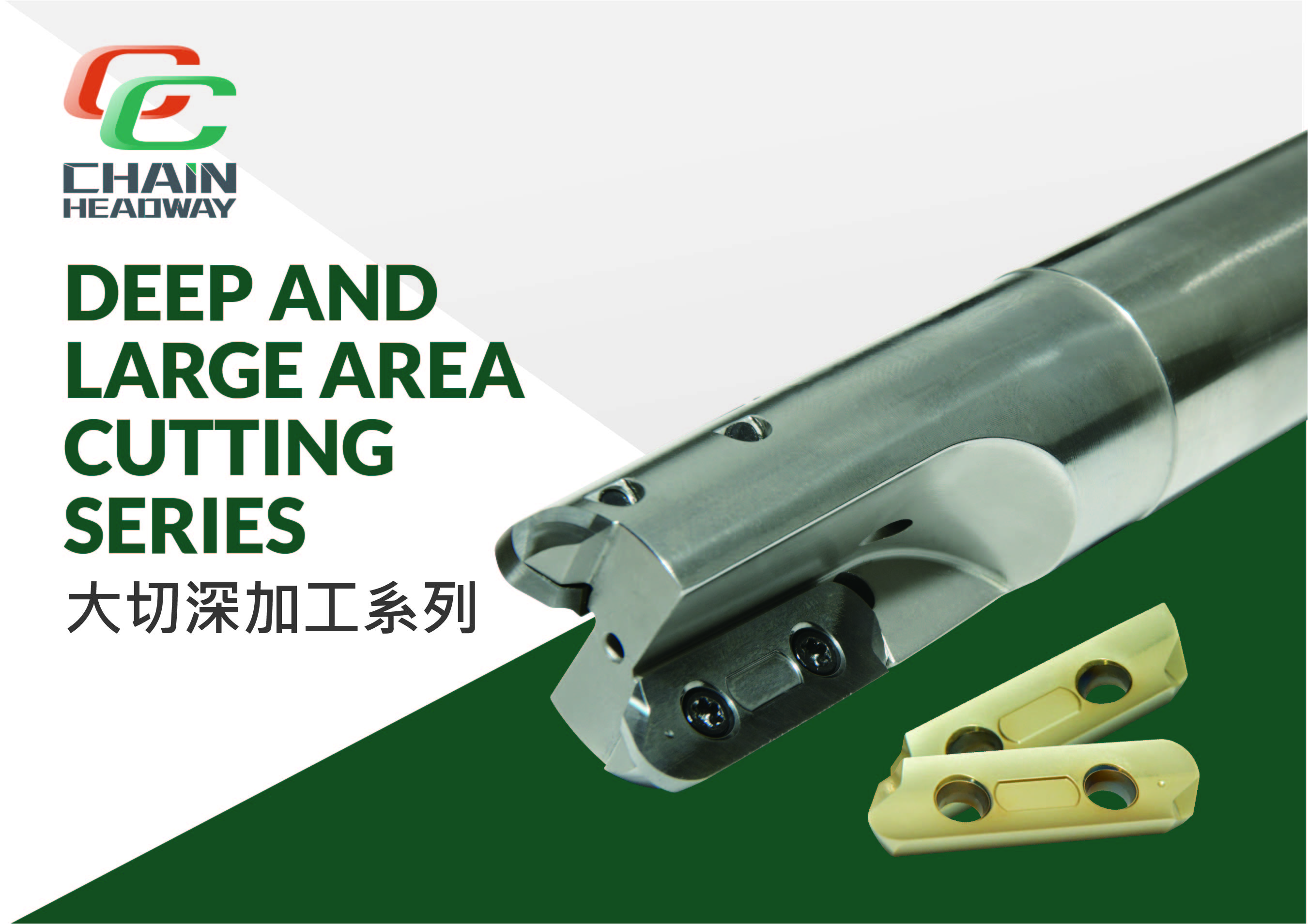

CHAIN HEADWAY CO., LTD

製品の説明 :

AECX32T3 Deep-Cut Long-Edge Hurricane Insert|High-Efficiency Solutions for Professional Cutting Tools and Indexable Inserts

In precision machining fields such as aluminum alloys, molds, and automotive components, stable cutting performance and superior surface quality are the keys to production competitiveness.

The AECX32T3 Deep-Cut Long-Edge Hurricane Insert combines high-precision edge design with innovative coating technology, specially engineered for deep cutting up to 30mm, achieving seamless surface finishing with no tool marks.

Core Advantages of AECX32T3

Seamless Surface Finish — No Tool Marks

With its precisely designed cutting-edge radius, the AECX32T3 eliminates tool transition marks during long-distance milling.

Tests have shown that the machined surface is smooth and refined, significantly reducing the need for post-polishing and finishing time.

HABOR PRECISION INC.

製品の説明 :

> Applications

Spindle, Linear Motor, Ball Screw, Grinding Liquid, CNC Cutting System, CNC Lathe, Other Machining Center

> Feature

Prevent deterioration of liquid.

Open coil type heat exchanger can prevent the obstruction problem of liquid circulating system.

Advance the speed of process.

Maintain the stability of dielectric fluid, advance the process quality.

Avoid fire risk cause by temperature rise and accumulating of dielectric fluid, advance the working safety.

Reduce the wastage of electrode.

Prevent the spreading of foul odor air, reduce the air pollution.

Easy operation and low noise.

Made of anticorrosive material.

TAIWAN MACHINE TOOL CO., LTD.

製品の説明 :

Strong casting and the perfect boxway stucture provides excellent cutting capacity for TTB-20MW Series. Sub-spinfle with milling function and Y-axis can satisfy customers' miltiple needs.

-The one cast base incorporates FEM analysis to achieve its optimal ribbing and structure to further enhance machine rigidity and stability.

-The 30 degree slant bed design has low center of gravity for easier swarf management and better erogonomic design. The TTB-20MW Series also offer optional rear type chip conveyor.

-To make sure the usage life of Y-axis ballscrew will get longer, there are three bearing on Y-axis ballscrew to enhance the support for pressure from top.

-The TTB-20MW Series can achieve maximum 20m/min for X axis and 25m/min for X axis. And the servo motors adopt absolute encoders for faster and more reliable positioning.