展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

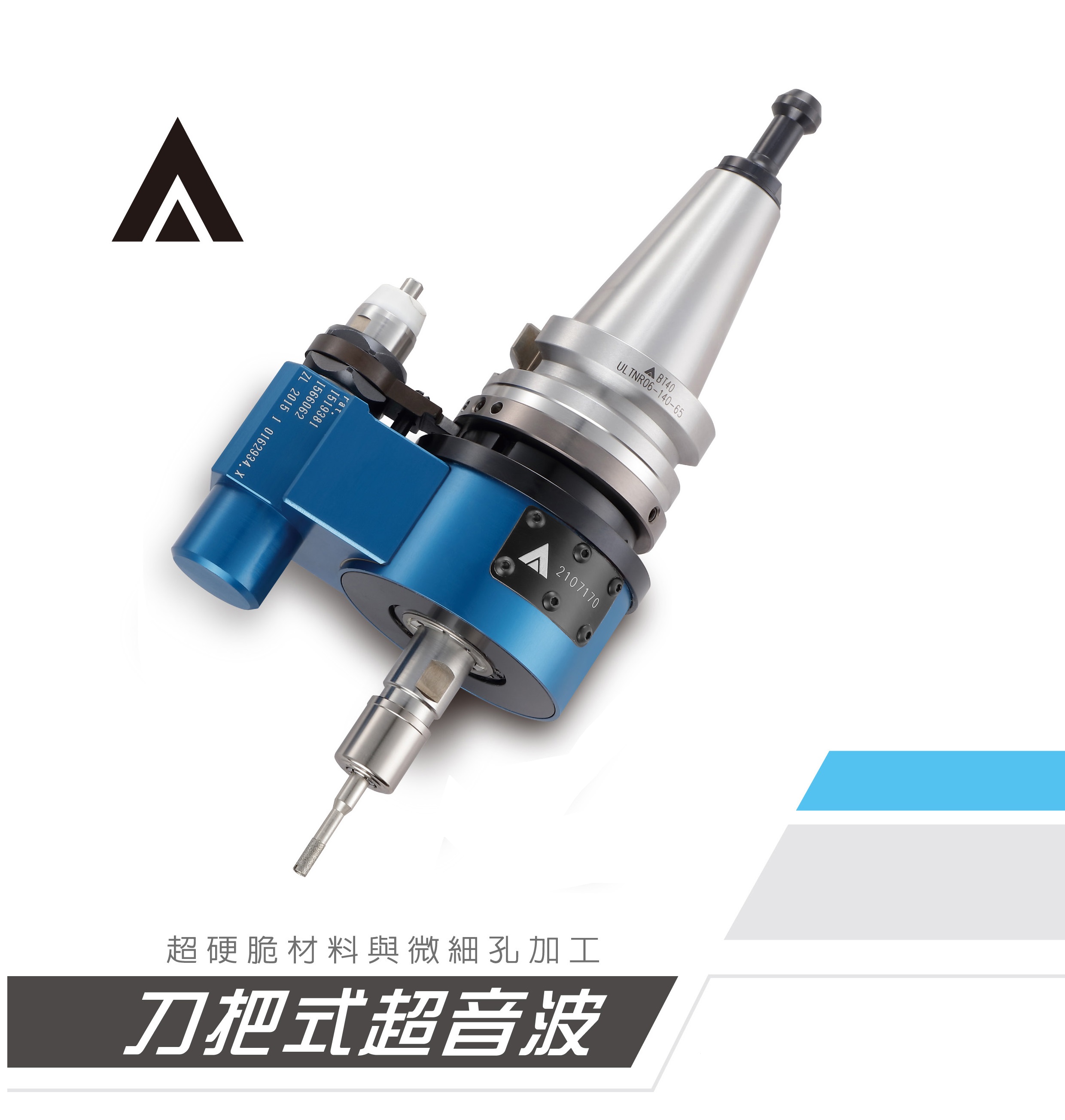

ACROW MACHINERY MFG. CO., LTD.

製品の説明 :

For Hard brittle material and micro holing drilling / Toolholder support for coolant function /

Clamping accuracy under 5 micro with the spring collets/ No need for special machine /

Easy to operate and install /

Reducing cutting resistance /

Improve surface roughness

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURES

Automatic ferrous or non-ferrous substrate

material measurement

Non-magnetic coating on ferrous metal

substrate and insulating coating on

non-ferrous metal substrate measurement

Audible and visual warning when tolerance

limits are exceeded

Statistical display of significant values such as

mean value, standard deviation, min, max values

Units of measurement μm/mils select

LCD display with backlight

Auto power off

FALCON MACHINE TOOLS CO., LTD.

製品の説明 :

Chevalier’s FSG-ADIV Series of surface grinders have several design features to shorten your processing and non-processing preparation while delivering high-precision workpieces year after year—functions you might not expect on such affordable machines: iSurface control, variable speed spindle, constant surface speed, loading detection and in-machine manual dynamic balancing.

FSG-ADIV Series grinders also feature tools to secure Big Data with Chevalier’s exclusive iMachine Communications System TM (iMCS).

This software package, combined with data analysis, enhances machine efficiency in the factory while enabling remote monitoring and diagnostics to track machine performance and identify potential problems before they begin.

JAR HON MACHINERY CO., LTD.

製品の説明 :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic tapping process. One operator can easily operate several machines at the same time.

3.By using proper master pitch gears(change gears A and B pair), highly accurate thread can be tapped. It is easy and quick to change different size.

4.The length of the tapping stroke can easily be adjusted for high accuracy which is suitable for tapping blind hole parts.

5.It has safe device to monitor the feeding, torque, radial, and clamping to keep TAP's long life and ensure safe working job.

6.It governed by PLC.

7.Long parts or those can't feed in vertical position are suitable.

8.Pre-work parts auto-checking and machine auto-stop if abnormal.

KAO FONG MACHINERY CO., LTD.

製品の説明 :

KG series gantry five-sided machining center is able to choose to carry all kinds of automatic additional head (90゜angle milling head, universal head, extension head, speed-up extension head ... etc.) auto tool changer. Standard verticaland horizontal tool changer magazine tool with optional multi-head library for automatic head exchange. Angle head part has 5° division curved tooth with standard high precision, and are able to select 1/2.5°division or watering function at the center. KG5A series bridge crane five-axis machining center is mainly designed for the processing demand on medium and large weight workpieceparts, with world-class high-quality five-axis manufacturing technology to complete the five-axis processing, it synchronously completes vertical, horizontal and a variety of free angle of processings, which substantially increases the processing efficiency. Floor-type workbench with super load capacity, up to 2.5 tonsweight per square meter. Adopting HSK-A63 24,000 rpm high-speed spindle or the heavy cutting spindlewithHSK-A100 10,000 rpm high-torque output depends on different maching applications, which greatly improves the processing efficiency of large workpiece, and fully meets the processing needs of different industries.

HOMGE MACHINERY IND. CO., LTD.

製品の説明 :

1) Patented stud bolt seat design can efficiently calibrate the clamping center.

2) It is recommended to operate with a Master Plate on a five-axis machine.

3) Compatible with Robotic Arms.

Product Data:

1.Vise body is made of High quality Steel (S50C) and its slideways gone through high-frequency hardening to achieve HRC50, which makes the whole part durable.

2.Detachable jaws are made of High quality Tool Steel (SCM440) and gone through carburizing to achieve HRC55. Since both sides are fixed size and able to be used as a datum, users can reverse them to increase clamping range.

3.The vise's clamping force can achieve 1300KG, the repeatability positioning precision of its clamping center is within ±0.02mm.

4.Users can calibrate the clamping center of vise by adjusting the screws on both ends.

5.The 45° dovetail structure with teeth on the upper jaw ensures the bottom of the workpiece to be firmly clamped.

6.Applications: precision machining of four-axis, five-axis, CNC indexing table and vertical and horizontal CNC milling machines.