展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

JASON AUTOMATION CO., LTD.

製品の説明 :

As part of Emerson Automation Solutions, AVENTICS is one of the world’s leading product brands for pneumatic components and systems. The pneumatic engineering brand provides products and services for industrial automation, as well as the food, packaging, medical, and energy technology industries. For our pneumaitcs brand, we also develop solutions for the commercial vehicles, marine, and railway technology sectors.

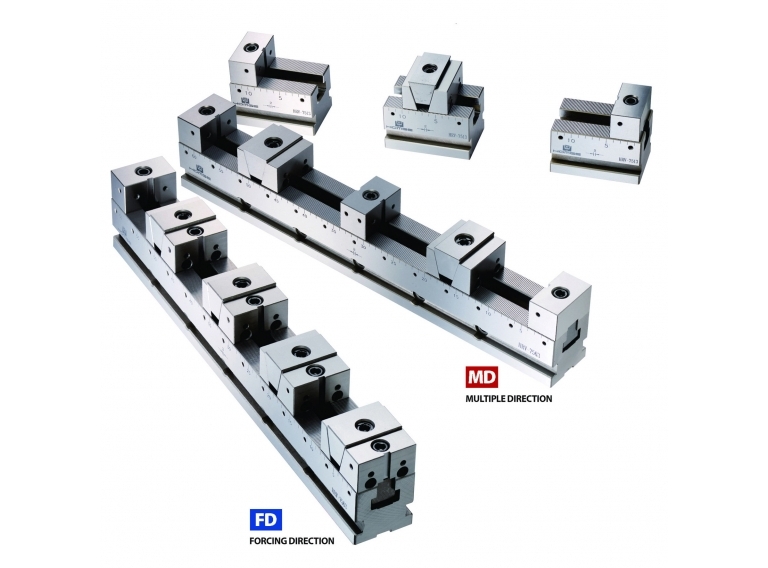

HOMGE MACHINERY IND. CO., LTD.

製品の説明 :

• Full set of this vise is made of Tool Steel with heat treatment more than HRC 60º of hardness and then ground precisely to ensures durability.

• HRV Vise is an adjustable vise, any shape of working piece, such as square, round, cylindrical or irregular shapes can be positioned quickly.

• This vise is suitable for Horizontal/Vertical and 4-Axis CNC Machining Centers, Surface Grinders,... etc.

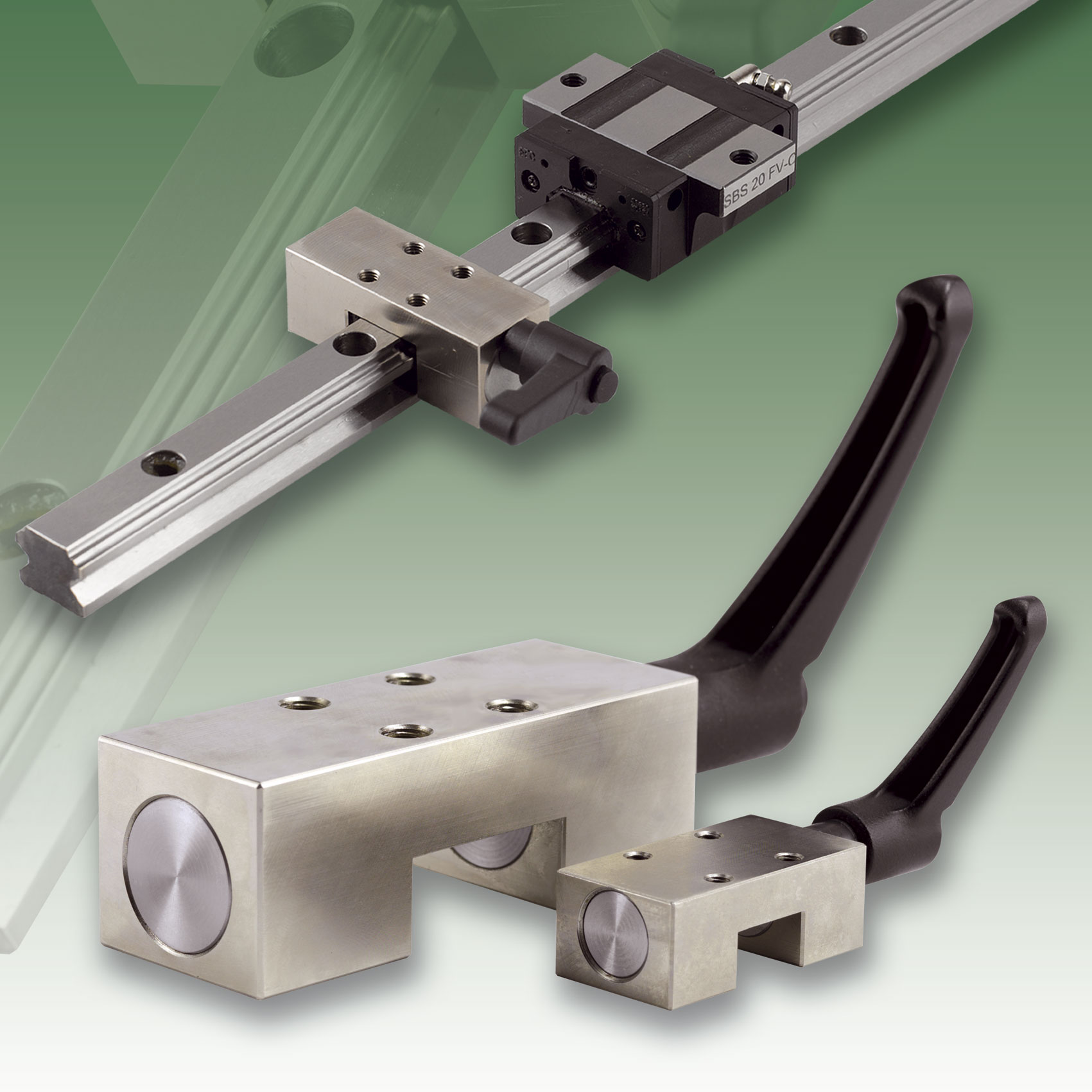

CAPTAIN SCIENCE CORPORATION

製品の説明 :

GENERAL DESCRIPTION RTB bearings (standabearings consist of a L-shaped inner ring - complet-ed with a washer -, an outer ring, two roller thrust bear-ings and a cylindrical roller bearing, full complement.Unitec has modified the inner design of RTB bearings and therefore load-carrying capacity and stiffness values may differ from the ones of past designs indicated on previous catalogues. The axial and radial load ratings have been calculated according to UNI ISO 76 and UNI ISO 281 standards.

RAISE PRECISION CO., LTD.

製品の説明 :

The compact, high-resolution MiniCODERs have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit. Without dedicated bearings, they are completely wear-free and maintenance-free. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments.

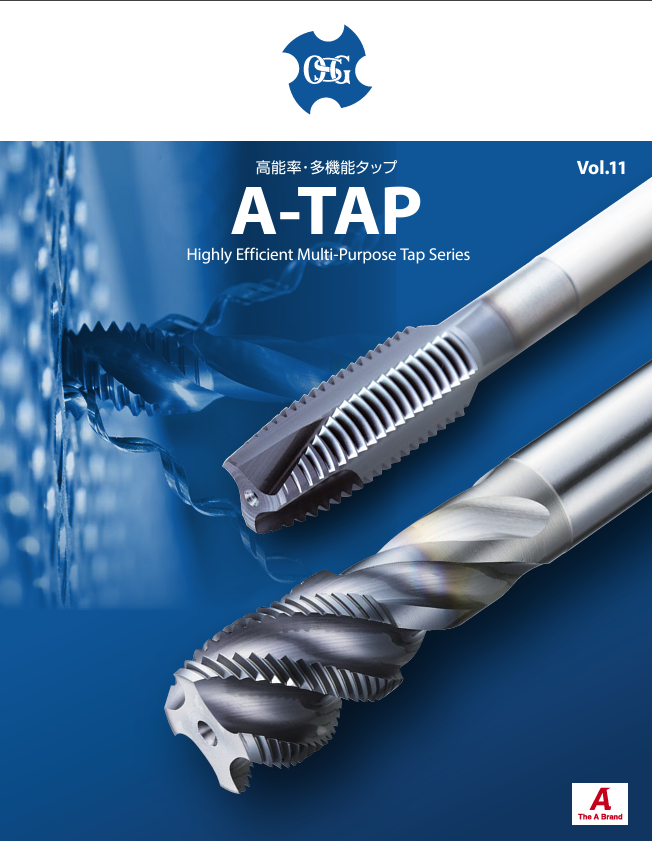

TAIHO TOOL MFG. CO., LTD.

製品の説明 :

The blade design that emphasizes cutting force and the unequal lead groove shape promote chip discharge and realize high-quality threading.

The lineup includes screw type for blind holes and through holes, and features that chips are discharged upwards.

The tip sample is for through holes, and the characteristic is that the chips are discharged downward.

There are two types of pipe specimens: parallel thread for mechanical bonding and tapered thread for tightness.

Chen Ying Oil Machine Co., Ltd.

製品の説明 :

1. CEN03 type is without timer (also could be controlled by Programmable Logic Controller) and has to work with volume distributors. With CAB or CBB type volume distributor, oil will feed during operation time. With CDB or T type volume distributor, oil will feed during interval time.

2. The discharge volume is fixed. The lubrication points of volume distributor supply a fixed flow of oil.

3. It has a spark-eliminator inside to prevent the sparks producing when the electric current is running. The spark-eliminator can avoid PLC (Programmable Logic Controller) being interfered.

4. CEN03 type has a pressure switch device and been set up as 8kg/cm2, which assures the oil volume of lubrication point and check if the piping works normally. The standard specification is NC (Normal Close) contact, which means if the pressure is abnormal, it will have signal. NO (Normal Open) contact is available on request.

5. It has a float switch that can detect the oil volume. When oil is lower than the minimum level, the float switch will automatically send a continuous signal.

6. It has a pressure gauge where an operator can check the pressure easily.

7. Do not press the force feed-oil (F button) more than three minutes in order to avoid overloading. When the temperature reaches 100℃, the sensor will be on to stop the motor continuing running about 5 minutes.

8. It can be used for the machines requiring strictly rationing oil flow. It is usually used for such as processing machines or projecting machines.