展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

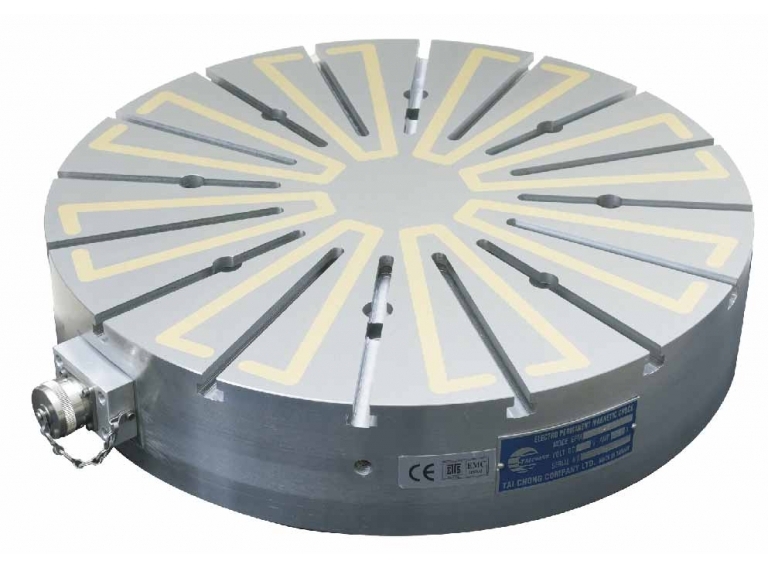

TAI CHONG CO., LTD.

製品の説明 :

用途: 車床,直立式車床,旋轉磨床等工作母機研削。<br />

特性:<br />

本體與面板一體成型加工完成。<br />

以電控操作,快速充脫磁場變換。<br />

以永久磁鐵吸著工件,沒有停電的危險性。<br />

吸磁作業面,螺栓孔可應用於模具及固定方式的變化。<br />

可配合彈性導磁塊,針對變形平面,作平面加工,大量節省調整時間,提高工作效率。<br />

結構剛性佳,配合精度穩定,適合高精度加工作業。<br />

與強力型電磁鐵比較,大幅度節省電力消耗。<br />

防水效果最確實,保證不漏水,不漏電。<br />

平均吸磁力18kgf/cm2以上。

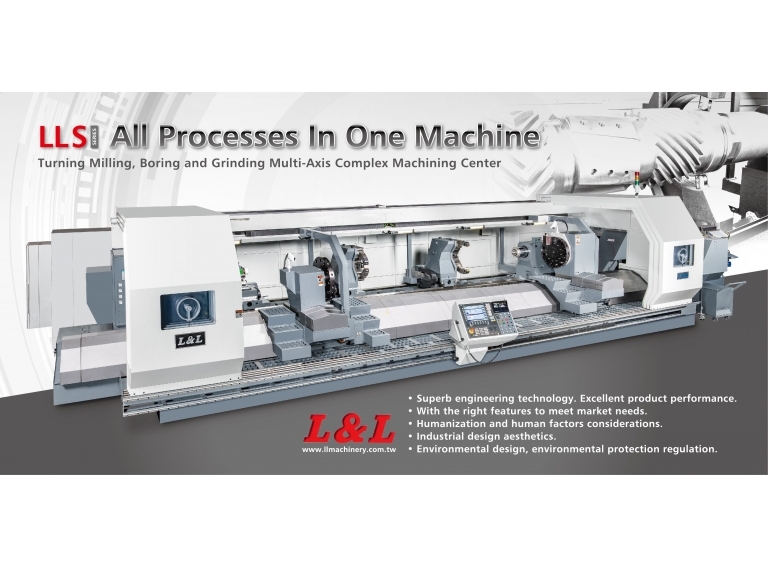

L & L MACHINERY INDUSTRY CO., LTD.

製品の説明 :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.

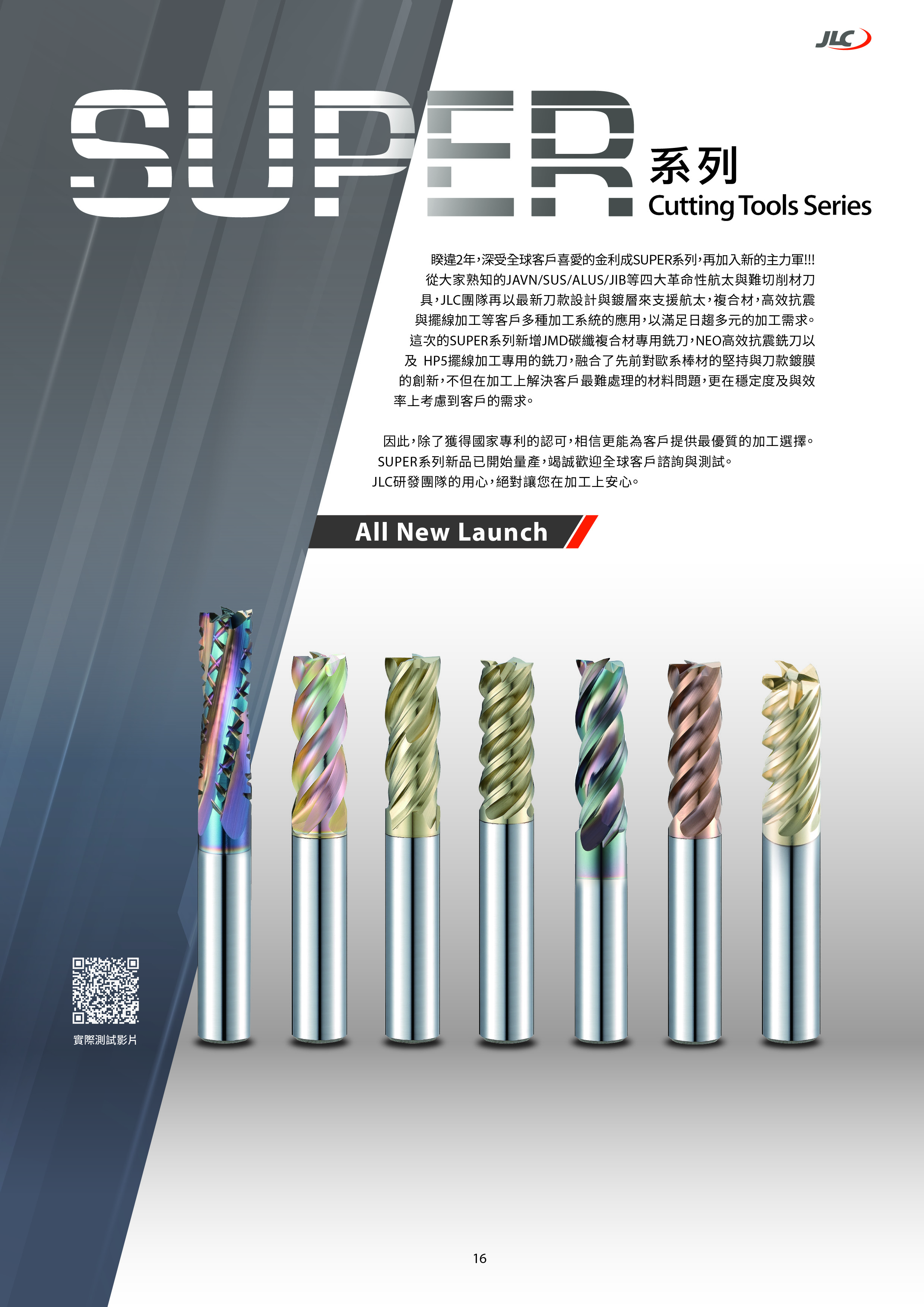

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

睽違2年,深受全球客戶喜愛的金利成SUPER系列,再加入新的主力軍!!!

從大家熟知的JAVN/SUS/ALUS/JIB等四大革命性航太與難切削材刀具,JLC團隊再以最新刀款設計與鍍層來支援航太,複合材,高效抗震與擺線加工等客戶多種加工系統的應用,以滿足日趨多元的加工需求。

這次的SUPER系列新增JMD碳纖複合材專用銑刀,NEO高效抗震銑刀以及 HP5擺線加工專用的銑刀,融合了先前對歐系棒材的堅持與刀款鍍膜的創新,不但在加工上解決客戶最難處理的材料問題,更在穩定度及與效率上考慮到客戶的需求。因此,除了獲得國家專利的認可,相信更能為客戶提供最優質的加工選擇。

SUPER系列新品已開始量產,竭誠歡迎全球客戶諮詢與測試。

JLC研發團隊的用心,絕對讓您在加工上安心。

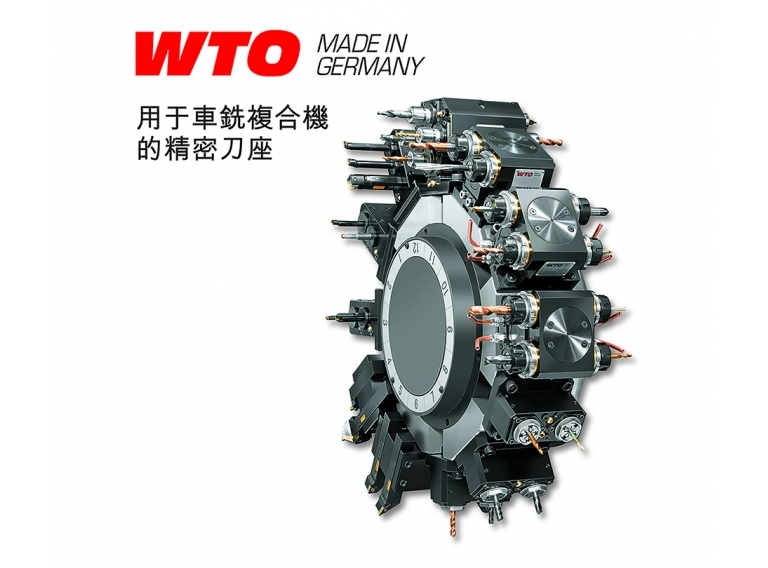

HUNG CHIH LIMITED COMPANY

製品の説明 :

MAPAL has a comprehensive portfolio of products and services. As such, individually designed custom tools and high-performance standard products are used to create machining solutions that optimally address the requirements for process reliability, precision and cost-effectiveness. Supplemented by intelligent services, the customer receives a complete package for the machining process.

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

Campro manufactures a family of Double Column Machining with size up to 5,200 x 3,100 mm travels. The machines offer the highest accuracies of any bridge mill on the market and can machine large parts efficiently with its rigid design. The extended Y-axis has full supported and constructed with a base/bed casting. The PV-XX16 (1,600 mm travels on Y-axis) is one-piece monoblock column structure that is bolted to the bed, delivers rigidity and stability. The PV-xx21 and PV-xx26 have wider door span and bigger machining range, the optional 1,000 mm Z-axis travel is best for attached head requested user.

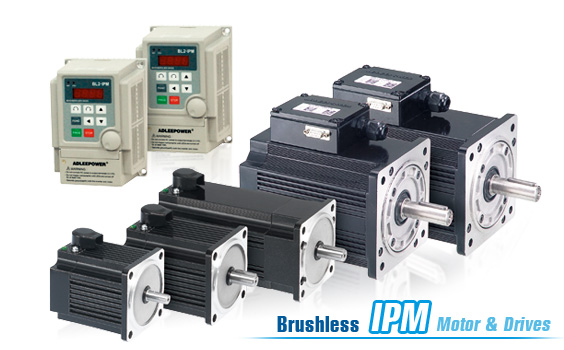

ADLEE POWERTRONIC CO., LTD.

製品の説明 :

Product applications:

Internal & External grinder 、Conveying equipment、Coffee roasting equipment、Centrifugal equipment、Polishing equipment、Emulsifying machine、Glass edge grinder、Auto polisher grinder, etc.

Brushless DC Motor

1. Minimize EMI and maintenance free. Low noise.

2. Specialized design to have smooth shaft rotation and improved reliability.

3. Brushless DC motor is light weight and compact size, higher power density, higher torque density and higher efficiency than conventional motors.

4. The structure has an excellent behavior in energy saving during heavy load operation. The high efficiency range is much wider than other motors too.

5. Built-in NTC thermal resistor to prevent over heat problem.

AC Driver

1. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

2. Convenient 220VAC driver power input from 60W. No more 24VDC power supply.

3. Built-in 24VDC mechanical brake control power.

4. Real motor speed display and signal output.

5. Panel control is always enabled with removed control or terminal control or RS485 control. Convenient for system set up or maintenance.

6. Excellent speed stability. Open loop and close loop speed control for selection.

7. With 0~5VDC, 0~10VDC and 4~20mA speed analog input.

8. Over current / heat / voltage, electric motor lock protection.

USYNC INC.

製品の説明 :

a. Through UE80CG, easy to operate.

b. It's flexibility.Not only use UE80CG but also use original G code on Mitsubishi controller.

c. Quickly set coordinate on "Easy set" function, it can reduce error form human operation.

d. It doesn't use G code to edit wheel's sharp,use drawing type to edit wheel's sharp.

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

TM Series is a Multi-Task machine that is capable of machining, drilling, and milling inclined holes, and curved surface or lathe processing. With curvic couplings in B Axis, it can not only achieve heavy cutting and machining but also, the max. occlusion torque is 7200Nm. The Electro spindle has 12000 RPM and max. torque is 102.7Nm. It is suitable for rough and finished machining. The lower turret with 12-position servo supports high-precision complex tasks.

Max. swing: 750 mm

Max. turning diameter: 630 mm

Max. turning length: 1640 mm

Bar capacity: 70 mm

X-axis travel: 600+50 mm

Y-axis travel: ±130 mm

Z1-axis travel: 1640 mm

Z2-axis travel: 1560 mm

B-axis angular stroke: 240°(-30°~+210°) mm

Spindle speed(chuck): 3500 rpm

Spindle nose(chuck): A2-8/10"

Spindle speed(electro): 12000 rpm

X/Z1-axis rapid traverse: 30 m/min

Y-axis rapid traverse: 24 m/min

X2-axis rapid traverse: 15 m/min

Z2/Z3-axis rapid traverse: 20 m/min

Tool storage capacity: 40 T