展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

TAIWAN RONG FU INDUSTRIAL CO., LTD.

製品の説明 :

V:Variable Speed

2F:Spindle Power Down Feed 0.12- 0.18 – 025mm/rev

Gearhead Drill Press with Cross-Slide Table

Rapid Spindle Changes by Quick Select Gear Shift Levers

High Speed Spindle / Quill

Fine Feed Hand wheel for Wide Range Control

Tilting Head Left 90° Right 30°

Suitable for milling and faster drilling setup

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURES

Automatic ferrous or non-ferrous substrate

material measurement

Non-magnetic coating on ferrous metal

substrate and insulating coating on

non-ferrous metal substrate measurement

Audible and visual warning when tolerance

limits are exceeded

Statistical display of significant values such as

mean value, standard deviation, min, max values

Units of measurement μm/mils select

LCD display with backlight

Auto power off

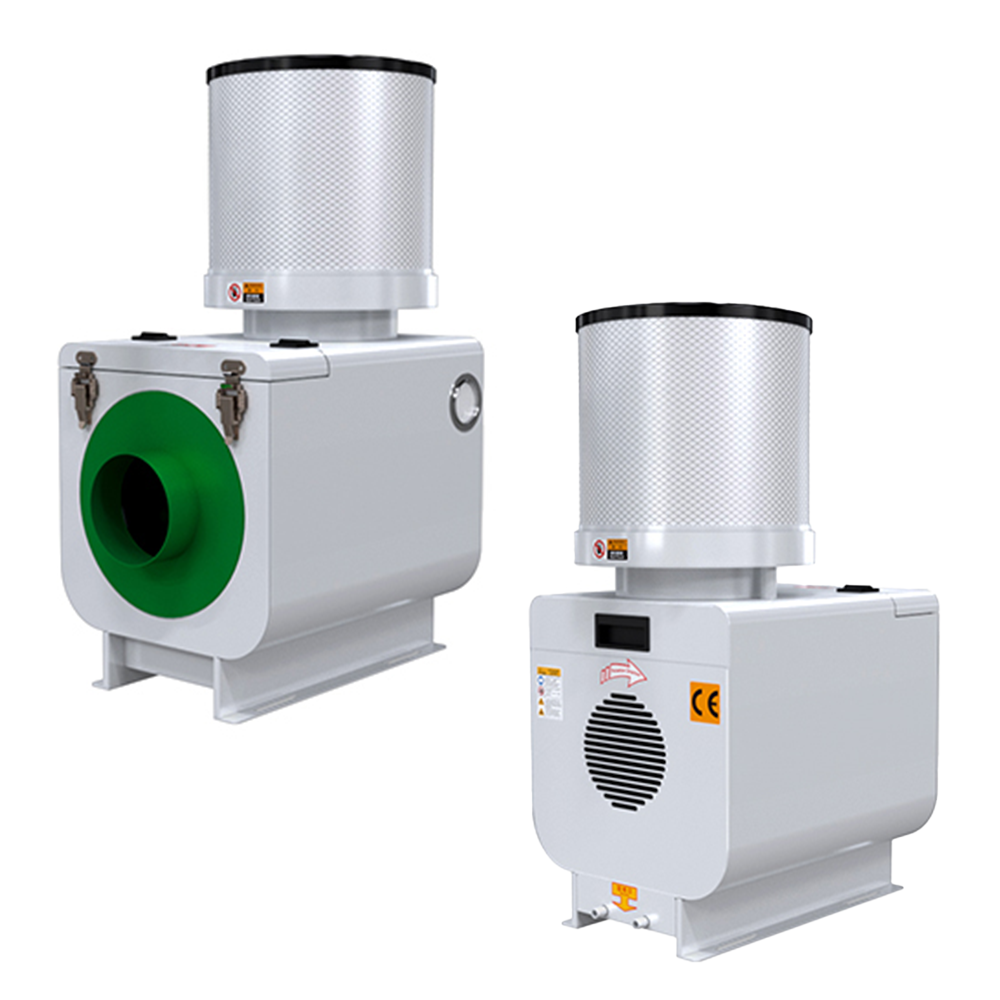

JU WEI MACHINERY CO., LTD.

製品の説明 :

The oil mist collector and filtration system unit is designed to conveniently mount to existing machinery minimizing installation costs. This highly stable filtration system is designed for maximum efficiency with low vibration and noise so it will not interfere with the operation of the machine it is attached to. The unique, high-speed impeller process provides a high suction, the centrifugal cyclone that achieves the best oil rejection. Further filtration steps then purify the air. Juwei oil mist collector (air cleaner) advanced air purification technology provides filtration efficiency as high as 99.95%~99.995%.

HABOR PRECISION INC.

製品の説明 :

Smart, energy-saving and high-accuracy DC inverter cooling machine can save more than 60% of electricity consumption through speed control and frequency conversion technology, and optimize the refrigerant system to reduce the amount of refrigerant used, which can also reduce the GWP value.

HIWIN TECHNOLOGIES CORPORATION

製品の説明 :

【ESG Sustainable Goal for Motion Control Components】

According to TrendForce research, the green factories will boost the global smart manufacturing market, which will reach $620 billion by 2026. As the concept of ESG sustainability has set off a wave of enthusiasm around the world, HIWIN linear motion components have also continued to focus on intelligent energy-saving innovation, providing simple, safe and modular designs to help customers upgrade from the inside out and embrace the trend of ESG energy saving!

The world’s first Intelligent 4.0 Ballscrew i4.0BS®, together with Intelligent 4.0 Guideway i4.0GW® and Intelligent Single-Axis Robot provide users to monitor health conditions of multiple machines and allow users to plan the production and pre-schedule the maintenance. The function of improving productivity and reducing carbon emission is also in line with the ESG sustainable goal.

-i4.0BS® multi-function sensors design with algorithm, effectively monitor the status of the Ballscrew. The users can monitor machines' conditions anytime.

-i4.0GW® sensor can be mounted on the block according to customers' demand. The system is fully compatible with i4.0BS®.

-The intelligent single-axis robot iSR has a modular design to meet the users' needs in various fields.

FACTORY AUTOMATION TECHNOLOGY CO. ,LTD

製品の説明 :

CNC Vertical Lathe VL-25M

Description

✔Unique RAM Exchange Interface Design

The RAM has three special features. First, the unique interface design enables automatic tools exchange.

Second, the built-in power tools provide milling function.

Third, the precision indexed positioning facilitates wide milling and turning applications. Such characteristics can keep free of cutting force applying on bearing, thus prolonging the bearing lifespan.

✔Worktable with high loading capacity

The maximum allowable load of the worktable is 20 tons with a diameter of 2,700mm and it utilizes high-rigidity, high-precision crossed roller bearing with proper preload that is capable of resisting cutting load from all directions.

Specification

VL-25M

➣Capacity Other Item

Max turning diameter Ø3000 mm

Max turning height 1800 mm

Max torque 32200 N-m

➣Table

Size mm Ø 2700

Table load 20000 kg

Table rotation 1.6~160 rpm

Motor α40, 6000i

Motor(continuous/30 mins) 37/45 kW

➣Stork and Rapid

X axis stroke(Horizontal)(RAM) 2100 mm

Z axis stroke(Vertical)(RAM) 1200 mm

X axis feed rate(RAM) 0-8000 mm/min

Z axis feed rate(RAM) 0-20000 mm/min

Z axis stroke(Vertical)(Cross rail) 1500 mm

Rapid of cross rail 400 mm/min

➣Automatic Tool(Changer)

Tool number 1cover+5turning+6milling, ISO50

Shank size □32, Ø32/Ø40/Ø50 mm

➣Servo Motor

Table AC 37/45 kW

Cross rail AC 5.5 kW

Hydraulic power AC 3.7 kW

Table lubricating AC 0.37 kW

Slide lubricating AC 0.025 (2 set) kW

X axis α30i kW

Z axis α40iB kW

Power spindle 15/18.5 kW

➣Dimension

Floor space(WxDxH) 6250x4696x6410 mm

Machine weight 30000 kg

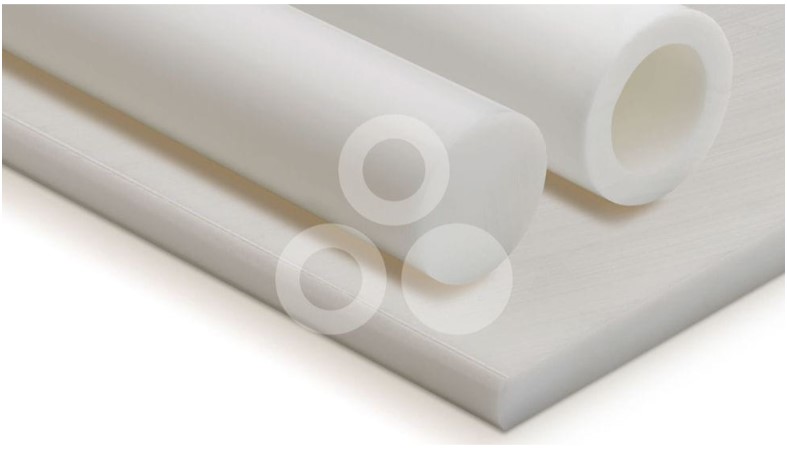

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

製品の説明 :

TECAFORM AH natural acetal is an unfilled porosity free POM-C with a unique balance of physical properties not available in most other thermoplastics. This copolymer acetal is an engineering plastic made for wide-ranging universal applications in many different industries. The key performance characteristics of unmodified POM copolymer include high mechanical strength and rigidity, excellent wear, low moisture absorption and excellent dimensional stability. Unfilled POM-C copolymer is manufactured by Ensinger under the tradename TECAFORM AH natural, and offers high crystallinity and a good degree of toughness (even in the lower temperature range), combined with good chemical resistance.