展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

YEU-LIAN ELECTRONICS CO., LTD.

製品の説明 :

We customize CNC MPG pendant encoder, comprise antistatic protection, reversed voltage protection from DC5V to 24V. Rugged model with IP67 dust-proof, oil-proof and waterproof, ergonomics design is much easier to use and smooth handling. Depending on actual needs, axis and multiplication selections can be set; function buttons, emergency stop switch, enable switch, indicator light and wire length are also optionally available.The MPG pendant handwheel is easy to install with multi-conductor cables, and can print the company logo on the manual pulse generator wheel cover. Manual pulse generator box, MPG box, Handle box MPG can choose 100 PPR pull-up, 25 PPR pull up, 100 PPR line driver, 100 PPR open circuit... etc.. Support CNC system like FUNAC, SIEMENS, MITSUBISHI, FAGOR, HEIDENHAIN, LNC, SYNTEC, GSK and other industrial CNC machines.

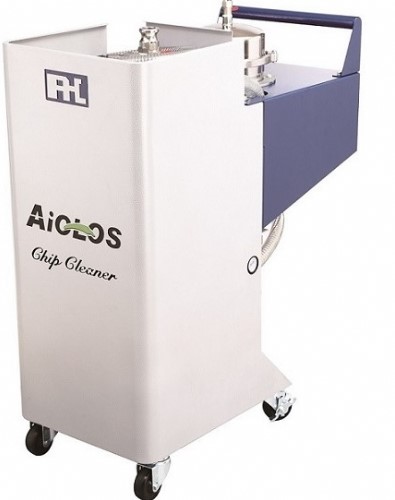

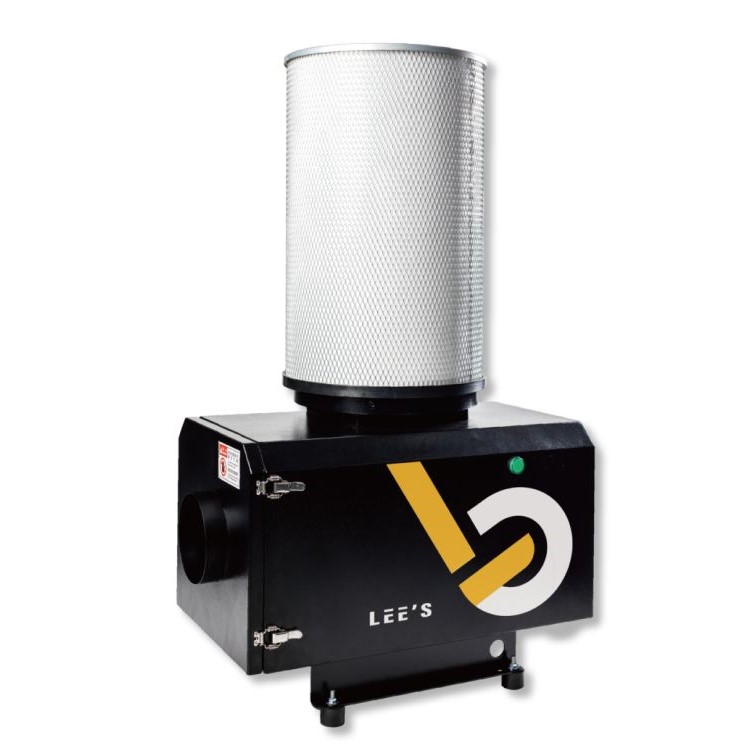

TOP POWER MACHINERY ENTERPRISE CO.

製品の説明 :

We exclusive patented technology and is committed to developing and producing products that meet global environmental protection goals. The machine is made of all metal and stainless steel materials. From the perspective of environmentally friendly equipment, it realizes the concept of net-zero and low consumables. Using the principle of physical centrifugation, a unique oil throwing device is designed, which can effectively extend the maintenance cycle and increase the filtration rate of oil smoke generated by the processing machine to more than 85%. In addition, the new generation design improves the performance of the machine with the same horsepower by 50%. Under the same efficiency, the power saving rate can be as high as 200% to 400%.

TAIWAN FANUC CORPORATION

製品の説明 :

In the current era of high personnel costs. Are you also considering importing automation, but you are worried that the technical threshold is too high and you will not be able to operate it!

Through FANUC QSSR, you can quickly connect with the robot, and use the familiar CNC operation interface to directly operate the robot, simplify the time of getting started with the robot, and quickly introduce automated production.

DKSH Taiwan Ltd.

製品の説明 :

The PC R series evaporators have a heating system based on a heat pump and operate under vacuum at 5kPa and around 30°C (86°F).

Heat exchange occurs within a conical jacket, and the boiling chamber inside part is cleaned by internal scrapers that continuously stir concentrate. This configuration is designed to produce a concentrate with a high final concentration and a distillate with low conductivity.

•From 0,1 to 2 m3/day – 0.02 to 0.37 US gpm of distillate

•Dramatic reduction of volumes and disposal costs

•Matter recovery

Extremely suitable when:

•the wastewater has a high initial content of dissolved or suspended solids

•the wastewater is already pre-concentrated

•the daily volumes are relatively small

•the distillate has to be of the highest quality

•the concentrate has to be recycled

TAIWAN MACHINE TOOL CO., LTD.

製品の説明 :

Strong casting and the perfect boxway stucture provides excellent cutting capacity for TTB-20MW Series. Sub-spinfle with milling function and Y-axis can satisfy customers' miltiple needs.

-The one cast base incorporates FEM analysis to achieve its optimal ribbing and structure to further enhance machine rigidity and stability.

-The 30 degree slant bed design has low center of gravity for easier swarf management and better erogonomic design. The TTB-20MW Series also offer optional rear type chip conveyor.

-To make sure the usage life of Y-axis ballscrew will get longer, there are three bearing on Y-axis ballscrew to enhance the support for pressure from top.

-The TTB-20MW Series can achieve maximum 20m/min for X axis and 25m/min for X axis. And the servo motors adopt absolute encoders for faster and more reliable positioning.