展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

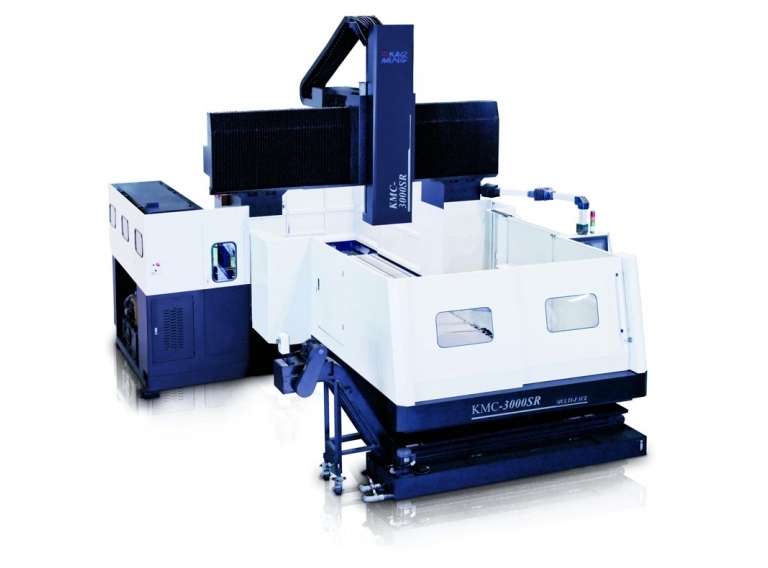

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 三軸採用方形硬軌設計,滑動件為全行程支撐,無懸伸下垂之問題,結構剛強適合重切削。<br />

<br />

2. 門寬2.1米以下,底座採用雙軌設計;門寬2.3米以上,底座採用四軌之滑動與滾動複合化設計。<br />

<br />

3. Y軸橫樑為階梯之軌道設計,段差70mm確保加工精度與穩定性。<br />

<br />

4. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

5. Y、Z軸滾珠導螺桿之安裝,其頭座與尾座係與橫樑及床鞍鑄成一體,確保最大剛性及精度。<br />

<br />

6. 機械式扭力限制器安全裝置,可避免機器在受到意外碰撞或操作錯誤時,重要機件不會因此被破壞。<br />

<br />

7. 刀庫為油壓分度馬達傳動;換刀臂之旋轉為油壓搖擺馬達驅動,確保ATC換到系統之快速、精確及穩定性。<br />

<br />

8. X軸8米以上四軌床身為線性導軌傳動,中央為主支撐兩側為滾子式履帶軸承輔助支撐,以增加傳動效率。<br />

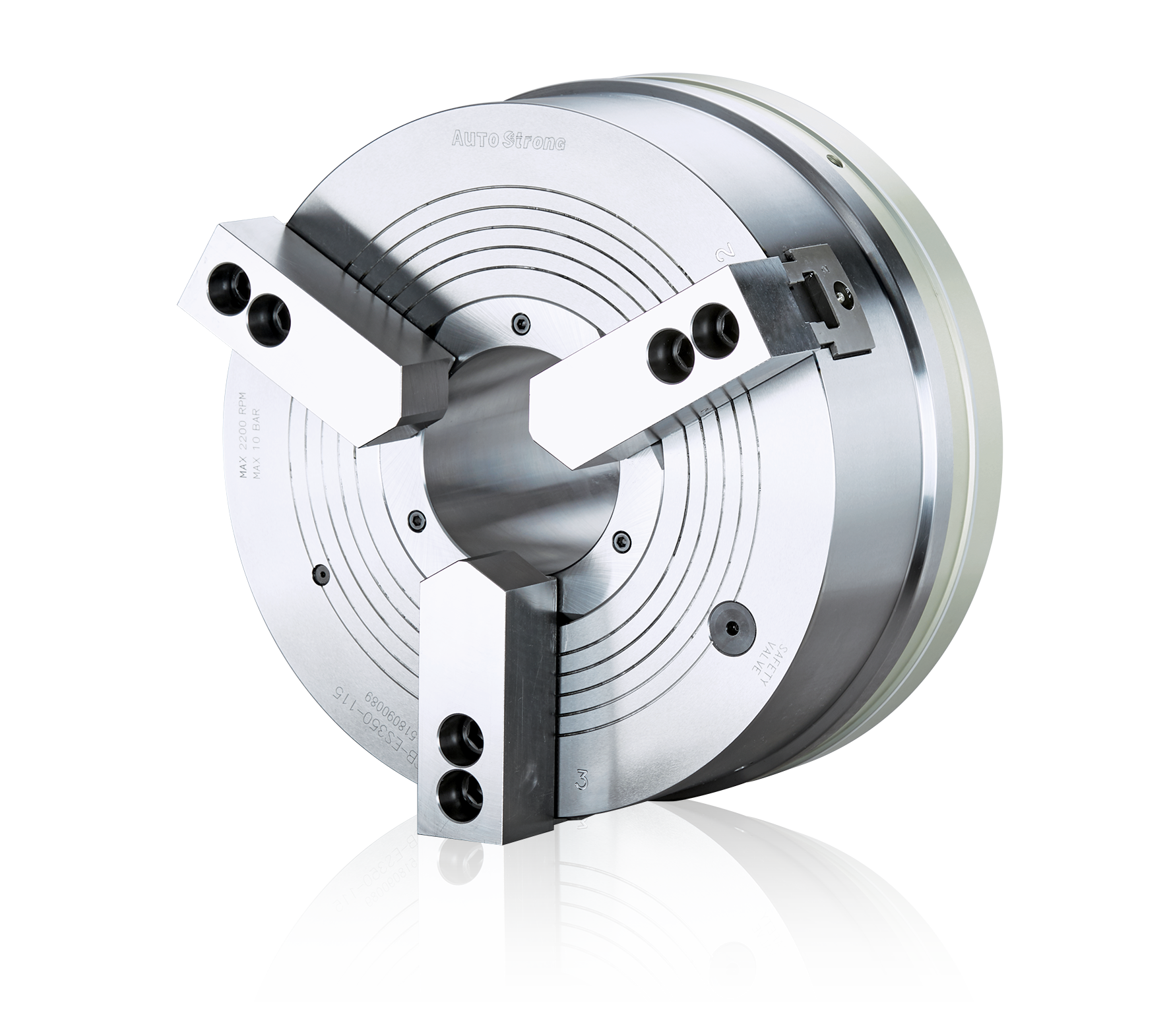

CLAMPTEK ENTERPRISE CO., LTD.

製品の説明 :

Clamptek’s CLF5H series designed with connecting rod structure which can operate conveniently. CLF5H series can also reduce the interference with loading and unloading operation, because when CLF5H series is in the unclamping state, it’s clamping arm can be put lower than holding position.

Clamptek’s CLF5H series’ clamping arm is very flexible. By reducing the interference of the surrounding equipment, CLF5H series can save lots of working space.

Clamptek’s CLF5H series equipped with special dust proof design and high sealing, which can prevent the cutting chips and coolant to infiltration. Therefore, CLF5H series can be used in more severe conditions.

Please kindly check the suggested operating pressure as below,

Max. operating pressure: 70 kgf/cm2

Min. operating pressure: 10 kgf/cm2

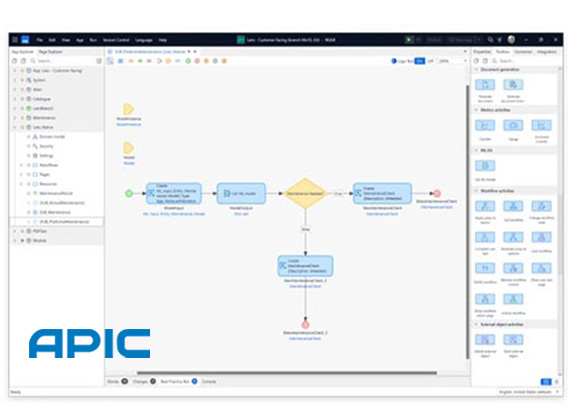

Alpha Precision Instrumentation Corp.

製品の説明 :

Siemens Mendix is a low-code development platform that helps businesses quickly build and deploy multi-device applications without extensive coding. Its cloud deployment features integrate with processes and data management tools, improving application maintenance and scalability. The platform can integrate seamlessly with existing systems and databases, making it suitable for optimizing internal business processes, building customized systems, and accelerating digital transformation.

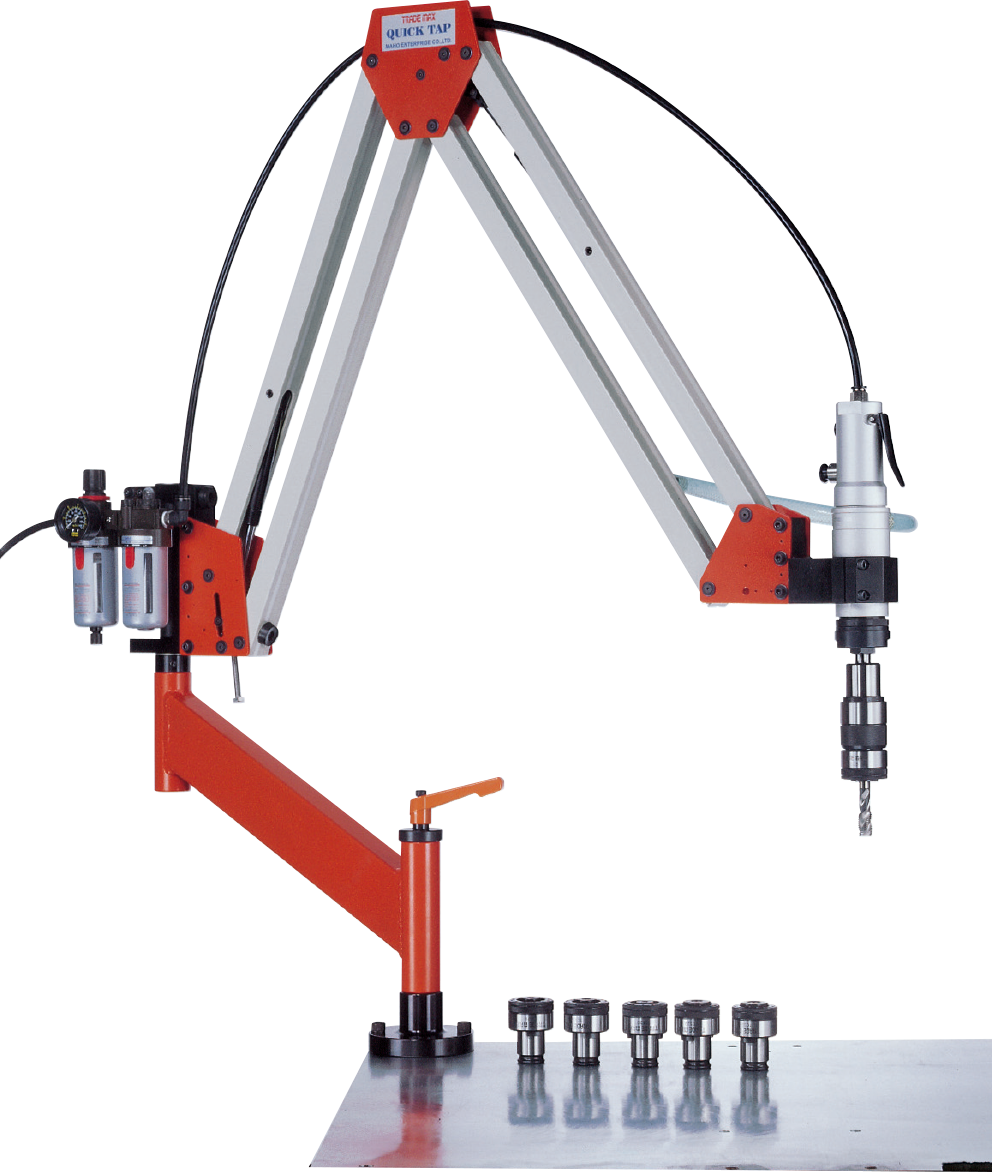

MAHO ENTERPRISE CO., LTD.

製品の説明 :

Pneumatic tapping machine is suitable for different size taps (from M2 to M27). The arm is equipped with lubricated for life bearings at all swivel points, provides weightless operation through the use of gas counter balance springs and permits the operator to bring the tap to the hole with ease.

DKSH Taiwan Ltd.

製品の説明 :

The PC R series evaporators have a heating system based on a heat pump and operate under vacuum at 5kPa and around 30°C (86°F).

Heat exchange occurs within a conical jacket, and the boiling chamber inside part is cleaned by internal scrapers that continuously stir concentrate. This configuration is designed to produce a concentrate with a high final concentration and a distillate with low conductivity.

•From 0,1 to 2 m3/day – 0.02 to 0.37 US gpm of distillate

•Dramatic reduction of volumes and disposal costs

•Matter recovery

Extremely suitable when:

•the wastewater has a high initial content of dissolved or suspended solids

•the wastewater is already pre-concentrated

•the daily volumes are relatively small

•the distillate has to be of the highest quality

•the concentrate has to be recycled

KAO FONG MACHINERY CO., LTD.

製品の説明 :

This series is the fix-column bridge type machining center which adopts fixed crossbeam and column, but moveable table . X and Y axes use the roller type linear guide way, and Z axis offers box way or linear guide way according to customer’s needs. In addition, it can be equipped with various types of manual attaching head (90 degrees milling head, universal head,extension head, multi-directional head etc.). Applicable to all kinds of parts processing, mold mold processing, aluminum parts and aerospace transportation parts processing industry etc.