展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

FACTORY AUTOMATION TECHNOLOGY CO. ,LTD

製品の説明 :

CNC Vertical Lathe VL-25M

Description

✔Unique RAM Exchange Interface Design

The RAM has three special features. First, the unique interface design enables automatic tools exchange.

Second, the built-in power tools provide milling function.

Third, the precision indexed positioning facilitates wide milling and turning applications. Such characteristics can keep free of cutting force applying on bearing, thus prolonging the bearing lifespan.

✔Worktable with high loading capacity

The maximum allowable load of the worktable is 20 tons with a diameter of 2,700mm and it utilizes high-rigidity, high-precision crossed roller bearing with proper preload that is capable of resisting cutting load from all directions.

Specification

VL-25M

➣Capacity Other Item

Max turning diameter Ø3000 mm

Max turning height 1800 mm

Max torque 32200 N-m

➣Table

Size mm Ø 2700

Table load 20000 kg

Table rotation 1.6~160 rpm

Motor α40, 6000i

Motor(continuous/30 mins) 37/45 kW

➣Stork and Rapid

X axis stroke(Horizontal)(RAM) 2100 mm

Z axis stroke(Vertical)(RAM) 1200 mm

X axis feed rate(RAM) 0-8000 mm/min

Z axis feed rate(RAM) 0-20000 mm/min

Z axis stroke(Vertical)(Cross rail) 1500 mm

Rapid of cross rail 400 mm/min

➣Automatic Tool(Changer)

Tool number 1cover+5turning+6milling, ISO50

Shank size □32, Ø32/Ø40/Ø50 mm

➣Servo Motor

Table AC 37/45 kW

Cross rail AC 5.5 kW

Hydraulic power AC 3.7 kW

Table lubricating AC 0.37 kW

Slide lubricating AC 0.025 (2 set) kW

X axis α30i kW

Z axis α40iB kW

Power spindle 15/18.5 kW

➣Dimension

Floor space(WxDxH) 6250x4696x6410 mm

Machine weight 30000 kg

AUTOMAZIONI INDUSTRIALI SRL

製品の説明 :

The VT 180/150 model features:

-1 Vertical extruder of 150 tons capacity (full-electric)- 180 Tons forging capacity- 80mm stroke- energy consumption: max. 20 kW/h- productivity: 6000 parts per hour- cycles per minute: 25 - burr-free forging With FORGE TRONIC presses you can produce a wide range of parts including: • Heating system fittings: HVAC fittings,fittings for gas applications, radiators and central heating fittings, gas plumbing,• Fittings for water supply: water meters, water plumbing, plumbing fittings, valves for water (ball o gate valves for water, elbows, Tee fittings, water intake, plumbing, strainers)• Fittings for hydraulics• Fittings for pneumatics ELECTRIC TECHNOLOGY: All the axes, the upper die, the four extruders and the unloading arm are directly driven by electric motors, allowing the user to regulate and monitor the process variables: position, speed, torque, etc. Thanks to a touchscreen monitor, the operator can set up the work cycle, the stroke, start and end parameters for each extruder.This way, the press is so accurate and precise that the forged parts have no burrs after forging and do not need any extra machining.The press has an integrated die lubrication through 16 upper nozzles and 16 lower nozzles and the required oil volume can be adjusted directly through machine settings.A specific Cad-Cam software allows the import of Step files of the die, workpiece, pins and pin bushings and other relevant settings can be saved, such as the start/ stop sequences of the pins. In addition, the software enables the operator to emulate the machine cycle and then the relevant file can be transferred directly to the Forge Tronic press. The press is available in different versions in order to meet the needs of different customers and reach various machine throughputs.

PHD Books Co., Ltd.

製品の説明 :

機械雜誌的第一品牌

充滿未來性之「機械新刊」具備三點特色:

第一,「選對的主題」。機械新刊每月所挑選的文章,都是對機械產業非常重要的指標性主題,多元化的內容整合,適合讀者每月翻看,汲取新知。

第二,「用對的人」。機械新刊之主編群結合產、官、學、研各界專家菁英,提供最優值的文章和綿密的產業資訊。現在是知識經濟的時代,在知識情商方面,哪一家公司有新產品?哪一家公司有好技術?透過機械新刊廣大的客戶產品資訊,讓您在通路行銷,研發製造各方面都能領先群倫。

第三,「做對的事」。機械新刊的市場定位及聚焦策略,考量傳承與創新之間的平衡,希望雜誌內容能兼顧廣度與深度,除了持續保持專業文章的深度,更重要是與市場貼近,完全掌握市場脈動,同時加入人文的溫度。

2017年起,博士文創事業經營機械新刊,以「廣遞新知,用心規劃」為宗旨,努力建立遍及海內外的讀者群。我們計畫以台灣為中心,向海外拓及讀者群,讓所有華語專業人士,都能翻閱機械新刊,從中獲得想要的資訊。另外,我們要使刊物成為客戶最佳的行銷利器。我們充分瞭解客戶的需求,讓機械新刊成為情資收集的專業平台,展示產品的最佳舞台。機械新刊紙本刊物搭配電商規劃,讓廠商在數位時代,將有更高更長久的曝光。

機械新刊充滿前景,「選對的主題」、「用對的人」、「做對的事」,我們的團隊專業,充滿競爭力,發行人出身機械產業,親身投入用心經營。機械新刊才剛要開始發光發熱,我們有絕對的信心,成為機械雜誌的第一品牌。

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

製品の説明 :

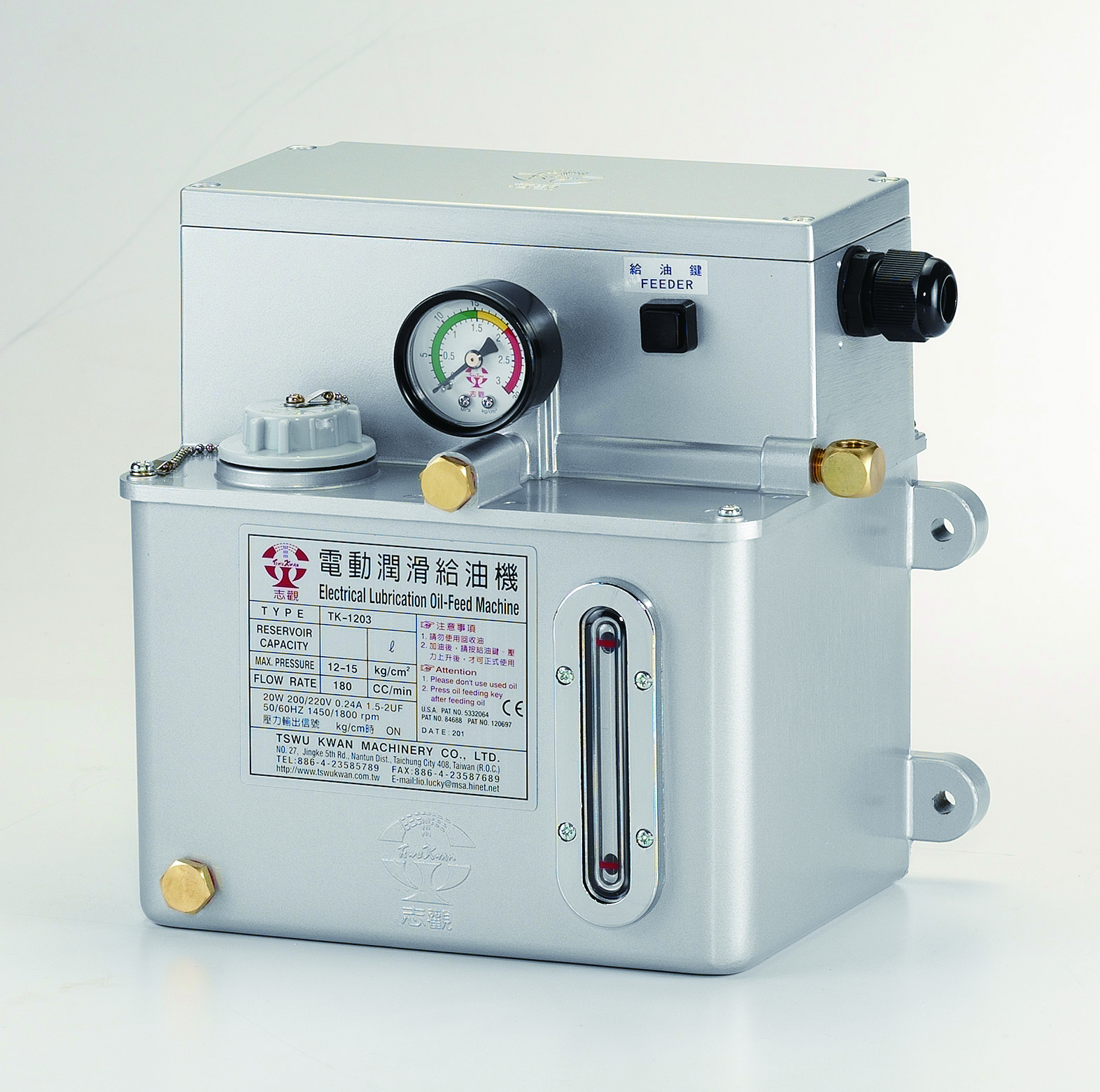

Compact hydraulic power packs are a type of hydraulic power pack. They arecharacterised by a highly compact design, since the motor shaft of the electric drive also acts as the pump shaft. Compact hydraulic power packs are designed to supply hydraulic circuits with hydraulic fluid.

The compact hydraulic power pack type INKA consists of the tank, the integrated motor and the radial piston pump or gear pump directly attached to the motor

shaft. The directly mounted electronic communication box with integrated realtime operating system allows the operating state to be recorded and visualised. The

measured values of the integrated multi-sensor (including the motor speed) can be passed on to the higher-level machine controls via standardised interfaces and processed there.

The consistently modular design of the type INKA means that different usage volumes and delivery flows can be realised quickly and easily from the modular

system. Compatible, ready-for-connection, complete solutions can be assembled easily using a wide range of connection blocks and the valve banks that can be combined with them.

Features and benefits

■ Prepared for condition monitoring with integrated sensors and communication box

■ Optimum efficiency through under-oil motor cooling, direct power transmission,and sophisticated heat dissipation

■ Suitable for nominal operating modes S2 (short period operation) and S3 (periodic intermittent operation)

■ Resource-saving due to small oil filling volume

Intended applications

■ Machine tools and material testing

■ Hydraulic tools

■ Handling systems

■ Presses and processing machines

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.

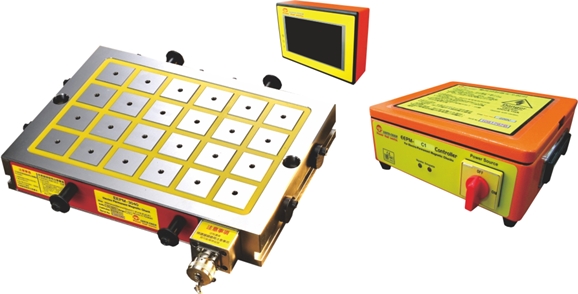

EARTH-CHAIN ENTERPRISE CO., LTD.

製品の説明 :

1.Suitable for CNC Vertical machining center (Can do 5 sides machining)

2.Suitable for thin, small , medium and large workpiece on varies cuttingmachining.

3.Suitable for thin, small , medium and large workpiece of the drilling and finishing machining.

4.Minimum size of workpiece required as 4 alternate magnetic square poles and above contacts is necessary for

optimum clamping.

5.More functions for cooperate with Induction Block and Spring Block.