展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

■Double built-in spindles with high accuracy C axis, max. speed 10000 rpm.

■The large number of available tools increases your productive time, efficiency to process turning, milling, drilling and back machining.

■Front tooling system provides 6 O.D. tools, 5 I.D. tools and 3 radial live tools plus 2 expansion adapter live tool units.

■Back tooling system on Y2 axis can have a max. of 8 live tools, also provide two deep drilling holders beside the sub spindle.

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

* Processing Method|Grinding

* Applications|Tungsten Carbide Blade Tool Processing

1. Excellent grinding ability, significantly reducing spindle load, save processing time and cost.

2. Tough texture and wear resistance characteristics to achieve the maintenance of tool dimensional accuracy.

* Processing Material | Tungsten Carbide

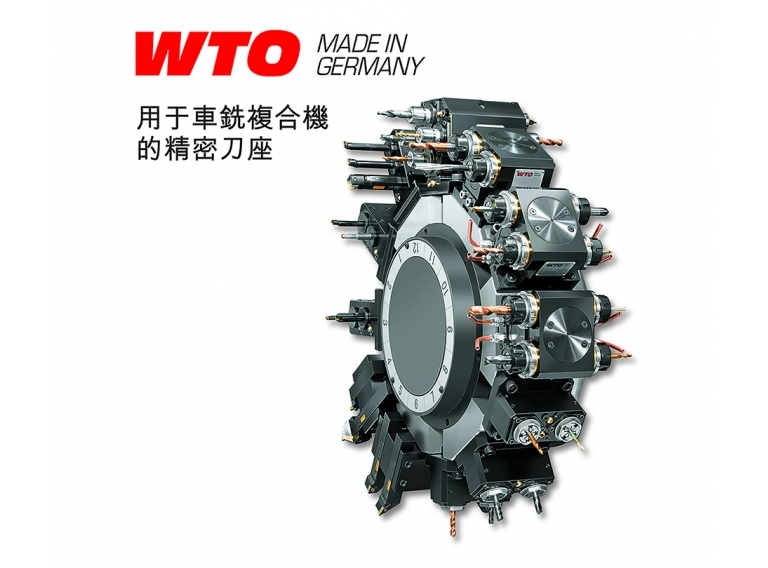

MING YANG MACHINERY CO., LTD.

製品の説明 :

Twin spindle configuration allows for both front and back machining.

Equipped with Sauter Turret

•C-axis functionality on both main and sub-spindle.

•Y-axis functionality promotes side and face milling, drilling, and tapping.

•12-station live turret ensures efficient milling, drilling, and tapping.

•A2-5 spindle nose.

6000rpm high speed spindle.

•High precision spindle accommodates collect chucks and 3-jaw chucks.

•X, Z, Y-axis feed rates: 24/24/10 M/min

RINGTECH INSTRUMENTS CO., LTD.

製品の説明 :

IFP vacuum cleaning machine can effectively clean any size and structure of complex metal products, great for either large or small amount of cleaning, it is also the best vacuum cleaning machine available for environmental protection and energy-saving! The cleaning cycle is carried out in a complete vacuum environment that the working environment is clean and odourless. During operation, the user can select different options from spray, rotate, ultrasonic, rinse...etc. based on the workpiece. With the cutting edge iFP cleaning technology, overcoming difficult cleaning situations such as cleaning blind holes, slits can be effortless. After cleaning, the chips and residual cutting oil will be separated from the cleaned workpiece, the chips are fully dried and can be collected from the filter; the residual cutting oil will also be separated from water and could be recycled and reused.

Facing the new industry trend and the new future, IFP cleaning machine is your best cleaning choice!

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

Angle encoders for rotary and tilting axes are indispensable for machine tools on which high positioning accuracy and a high machining rate are essential. Because angle encoder measure angular motion of the axis directly and immediately. Mechanical transfer elements therefore have no influence on position measurement, both kinematics errors and the influences of forces are measured by the angle encoder and considered in the position control loop. This can eliminate a number of potential error sources: Gear errors, reversal error, errors due to deformation of the drive mechanics by machining forces.

PEIPING PRECISION ENTERPRISE CO., LTD.

製品の説明 :

*Automatic spindle polishing control.

*Keep the precision of spindle and no damage to spindle body.

*One setting for the maximum convenience of operation.

[After Use]

*Extend the life of cutting tools.

*Increase workpiece accuracy.

*Reduce the spindle vibration and extend the life of spindle.

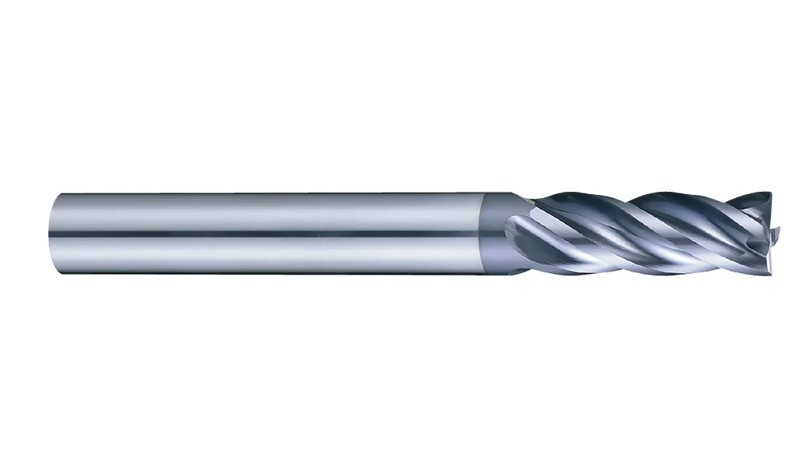

7-LEADERS CORP.

製品の説明 :

Multipurpose End Mills- 4 Flutes

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Obviously improve tool life with Nano multilayer coating AlTiCrN.

Suitable for different kinds of materials cutting.

JAR HON MACHINERY CO., LTD.

製品の説明 :

1.The machine can be attached double spindle head and work efficiency can be more increased.

2.Both cutting TAP and forming TAP are suitable.

3.The length of the tapping stroke can easily be adjusted for high accuracy which is suitable for tapping blind hole parts.

4.It has safe device to monitor the feeding, torque, radial, and clamping to keep TAP's long life and ensure safe working job.

5.It can install additional hopper to increase automatic working.

6.It can install additional sheet metal cover to gain more safety and reduce noise.

7.Pre-work parts auto-checking and machine auto-stop if abnormal.