展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

PALMARY MACHINERY CO., LTD.

製品の説明 :

The new CNC internal Grinding Machine from PALMARY features optimal structural design, and an elegant appearance combined with advanced CNC control. The all new series will bring internal grinding technology into a new era. The structural parts of the machine are manufactured from high quality cast iron for deformation-free performance year after year. The entire machine is precision built throughout to guarantee the best possible grinding accuracy you can find anywhere.

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

Twin spindle & twin turret design, it can turn the different parts on the spindle and identical parts on both spindles at the same time. Integrated with 3-axis robot arms, to reach different OP and automation requested. Considering the turning efficiency, with automation high-speed robot reduces the loading/unloading time, with a high rigidity stricture design to increase the stability. On the other hand, the multiple types of robot arms will be able to satisfy the different demands of the client.

Max. swing: 290mm

Max. turning diameter: 290mm

Max. turning length: 220mm

X-axis travel: 195+5mm

Z-axis travel: 300mm

Spindle speed: 3500rpm

Spindle nose: A2-6

Chuck size: 10"

Spindle motor power: 11/15kw

Number of tool stations: 12T

ASMITH MANUFACTURING COMPANY

製品の説明 :

Dust-resistant, waterproof (IP66), resistance to heat and corrosion.

Patent: Pawl is fixed by 4 positioning points and the grooved shaft-bolt, easy for assembly and adjustment. Need only to slide the pawl through the shaft-groove to the correct position, more stable and accurate.

Left, right and top opening. The pawl moved forward and reversed vertically 3mm while the compression latch is opened and closed.

Used widely for door panel of general cabinet boxes.

Pawl can be easily positioned to accommodate the suitable compression.

In accordance with RoHS.

➤Material-body and lever: SUS304(stainless steel)-vibration ground and brushed finish in front.

➤Material-shaft, pawl and mounting bracket: SUS304(stainless steel).

YI CHANG MACHINERY CO., LTD.

製品の説明 :

This video features the Yi Chang Machinery model HD750 hydraulic automatic drilling machine assemble with a cam indexer combination. This combination not only achieves the rapid completion of multi-hole drilling requirements on a single workpiece but also significantly improves work efficiency, making operations much easier.

This hydraulic automatic drilling machine utilizes its efficient cam indexer , allowing you to accomplish multi-spindle drilling in a short amount of time. Whether it's for mass production or individual pieces, the machine proves to be exceptionally productive. Operating this machine is straightforward, even for beginners, and its high-efficiency design enables you to tackle work challenges with ease.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

JAINNHER MACHINE CO., LTD.

製品の説明 :

The aesthetic design of JHT-4010 will convince you, as well as the technology of the fast-moving hydrostatic guideway system.

The 3500rpm built-in spindle, the ability to carry a Ø510mm grinding wheel, and a wheel head axis capable of rotating ±30° for thread grinding are impressive features enabling you to move your manufacturing to a new level.

Jainnher's officially website:www.jainnher.com

Jainnher's Youtube:

https://www.youtube.com/user/GrindingMachineTech/videos

SING CHIUN ENTERPRISE CO.,LTD.

製品の説明 :

(1) Great tensile performance, great camber.

(2) Thermal resistance range:-15℃~105℃ , Protection

degree IP68.

(3) Inner conduit is made of iron metal with zinc plating,

out layer is covered with PVC, with of waterproof

and dust proof.

(4) PT705 (3/8"~ 1 1/4") Inner conduit with copper

earth wire.

(5) According to IEC Section 351, the conduit must be

additionally attached with one grounding cable

when PT705 (1 1/2"~ 4") is constructed.

(6) Apply to conduit protection of electrical equipment

under UL standard, detection instrument, industrial

equipment and hardware work piece.

(7) Apply to electrical conduit for heavy industrial

machine motor, petrified and chemical machine,

plastic manufacturing building, power transformer

and ship manufacturing.

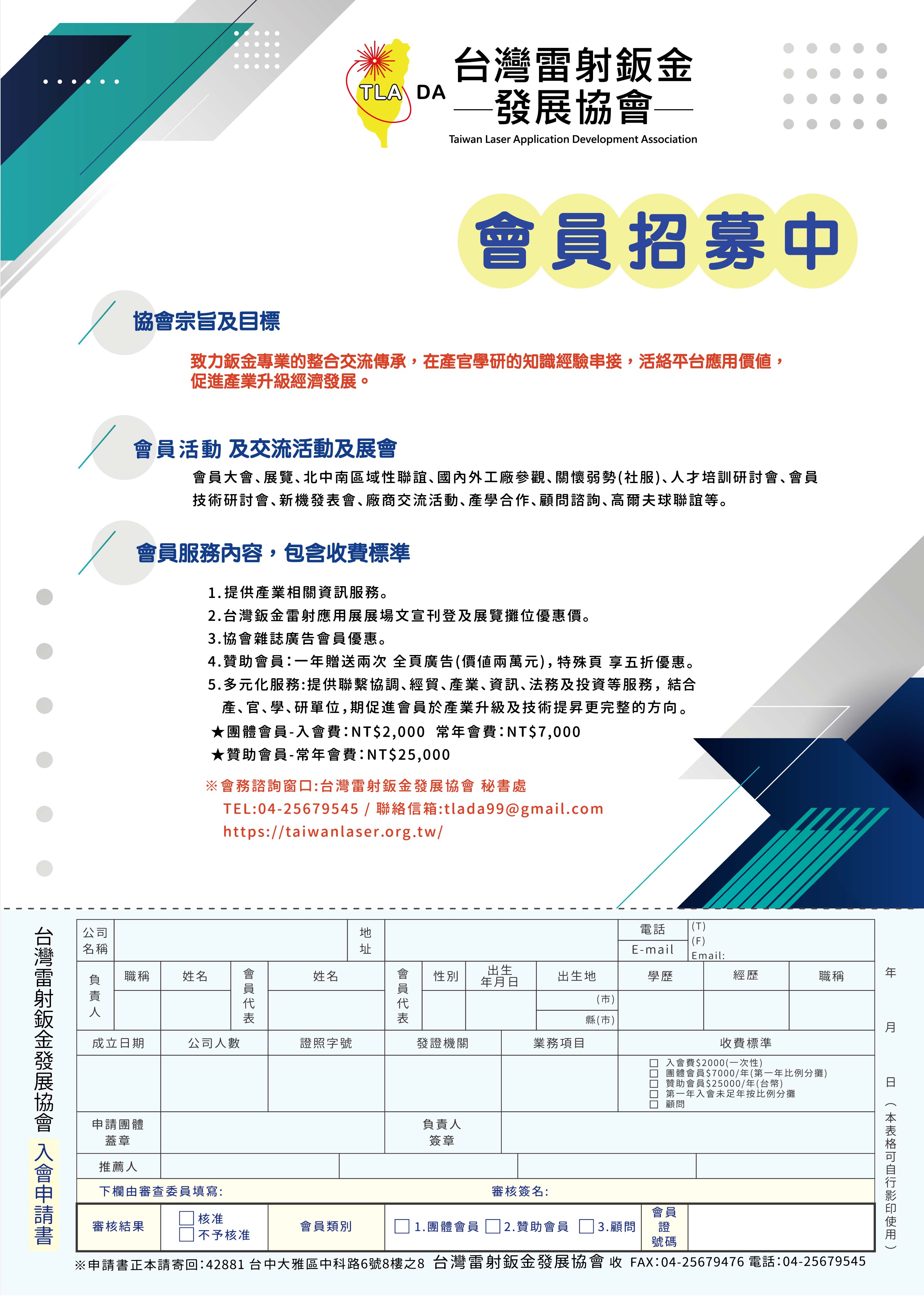

Taiwan Laser Application Development Association (TLADA)

製品の説明 :

Established by law, non-profit social organization, that with the government to promote production

Industrial upgrading, and promote industrial upgrading professional laser application technology of energy produced by the Council and,

Government, and academia to exchange, establishment of industrial development consensus and dialogue with the government of the pipeline. "

Simultaneously through various international exchanges, and actively explore business opportunities, boost the global competitiveness of Chinese enterprises, the development phase for the case with the world。