展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

SHAN HUA PLASTIC INDUSTRIAL CO., LTD.

製品の説明 :

善化工業股份有限公司專業生產符合SAE100R7、SAE100R8規範之高壓油管。<br />

擁有最多樣尺寸、顏色、配置及包裝供客戶選擇。<br />

產品特點為重量輕,約橡膠管重量的1/2,受壓力時,曲線不變。<br />

採用耐候、耐磨擦、耐油性的特殊材質。可耐用各式酸鹼,並可選擇外管顏色,便利於顏色管理,亦可選擇導電和非導電型,以確保機台人員的安全。<br />

用途方面,除了可以完全取代傳統橡膠管外,可用於各式高壓液體、高壓氣體、噴塗裝機、清水溝車、農業機具、轉向系統、船舶用管等,各式液、氣體配管均可使用。<br />

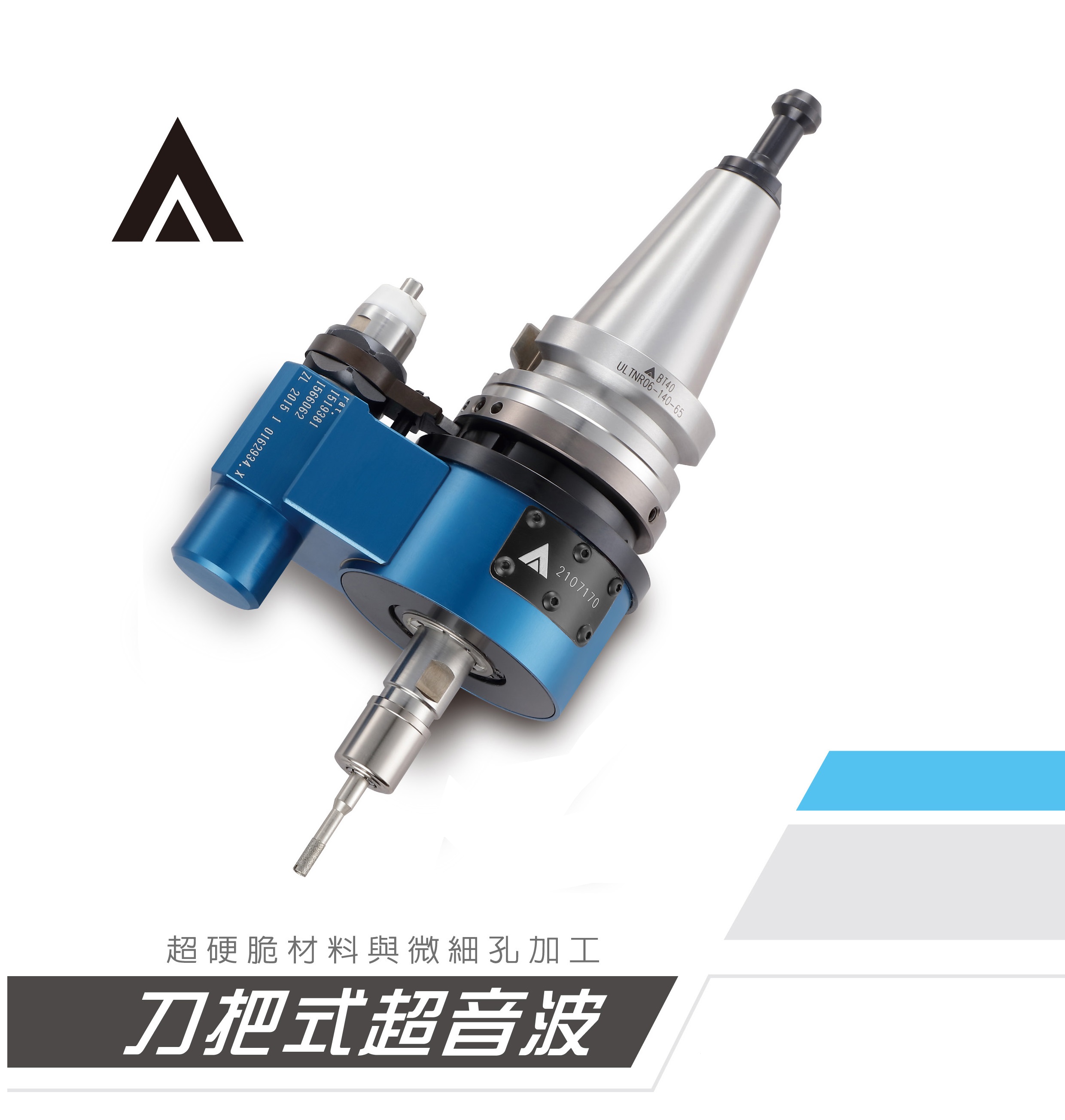

ACROW MACHINERY MFG. CO., LTD.

製品の説明 :

For Hard brittle material and micro holing drilling / Toolholder support for coolant function /

Clamping accuracy under 5 micro with the spring collets/ No need for special machine /

Easy to operate and install /

Reducing cutting resistance /

Improve surface roughness

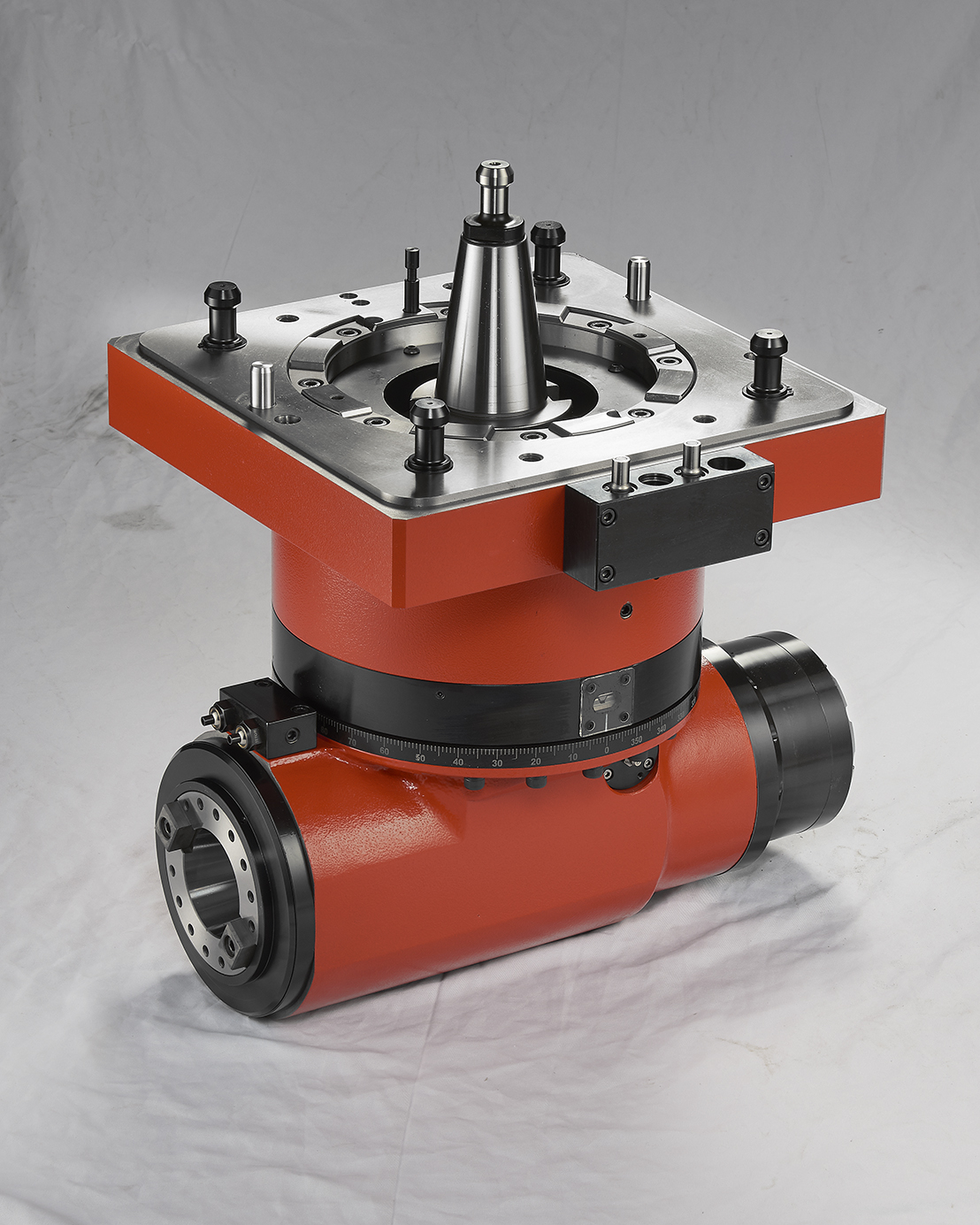

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

PRECISION MOTION INDUSTRIES, INC.

製品の説明 :

In order to meet the market demand for high-speed and high-precision performance in the machinery industry, it is necessary to increase the motor speed and axial feed speed. Therefore, PMI developed a high-speed V-type ball screw to meet this stringent demand.

Feature:

► The Dm.n value has been highly improved.

► lower vibration and noise.

► The size of the nut is reduced by 10 ~ 20 %.

► Improved the smoothness and stability.

Hainbuch GMBH

製品の説明 :

Increasing process stability is crucial for optimizing production. Hainbuch offers an extremely innovative solution here with the new Maxxos T212 mandrel: The Maxxos T212 is a mandrel with a pull-back effect and is therefore ideal for 5-sided machining of the workpiece on both turning and milling centers. Thanks to the hexagonal pyramid shape, the Maxxos mandrel has been developed for maximum accuracy and feed rates. The hexagonal mandrel achieves a significantly higher holding power than the round Mando mandrel and enables up to double the torque transmission and corresponding cutting rates. Hainbuch offers the Maxxos T212 mandrel in 12 sizes for the diameter range 8mm to 200mm. The Maxxos T212 mandrel has no draw bolt. It is therefore ideal for workpieces with blind holes and very short clamping lengths without any loss of clamping length.

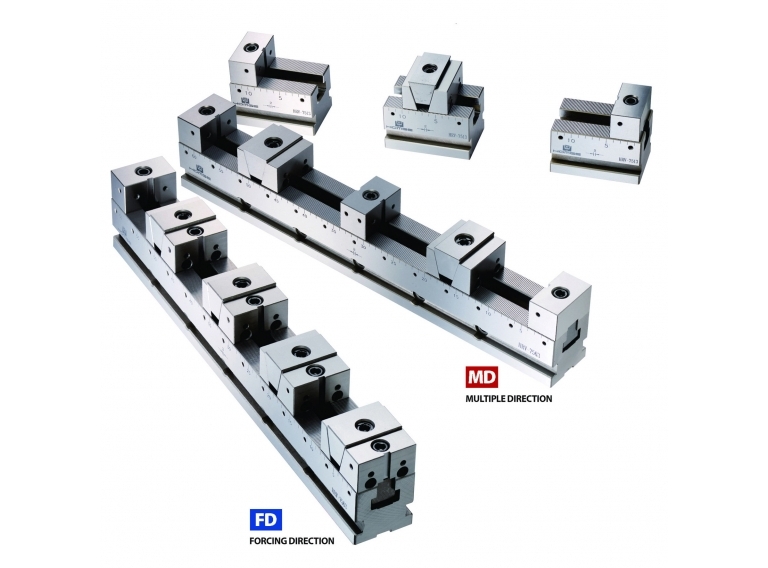

HOMGE MACHINERY IND. CO., LTD.

製品の説明 :

• Full set of this vise is made of Tool Steel with heat treatment more than HRC 60º of hardness and then ground precisely to ensures durability.

• HRV Vise is an adjustable vise, any shape of working piece, such as square, round, cylindrical or irregular shapes can be positioned quickly.

• This vise is suitable for Horizontal/Vertical and 4-Axis CNC Machining Centers, Surface Grinders,... etc.

HABOR PRECISION INC.

製品の説明 :

Smart, energy-saving and high-accuracy DC inverter cooling machine can save more than 60% of electricity consumption through speed control and frequency conversion technology, and optimize the refrigerant system to reduce the amount of refrigerant used, which can also reduce the GWP value.

TOP POWER MACHINERY ENTERPRISE CO.

製品の説明 :

The latest crumb collection and +1um precision filtration machine. This bottom debris recovery filter is equipped with a 1.5-inch large suction pump, which can quickly collect and dry the bottom debris and sediment in the water tank, allowing customers to clean it conveniently. This machine is equipped with a multi-functional stainless steel filter barrel that can collect coarse bottom debris. At the same time, using our patented technology, there is no need to replace the filter barrel, and it can continuously perform precision filtration up to 1um, thereby intercepting and filtering impurities and suspended particles in the water.

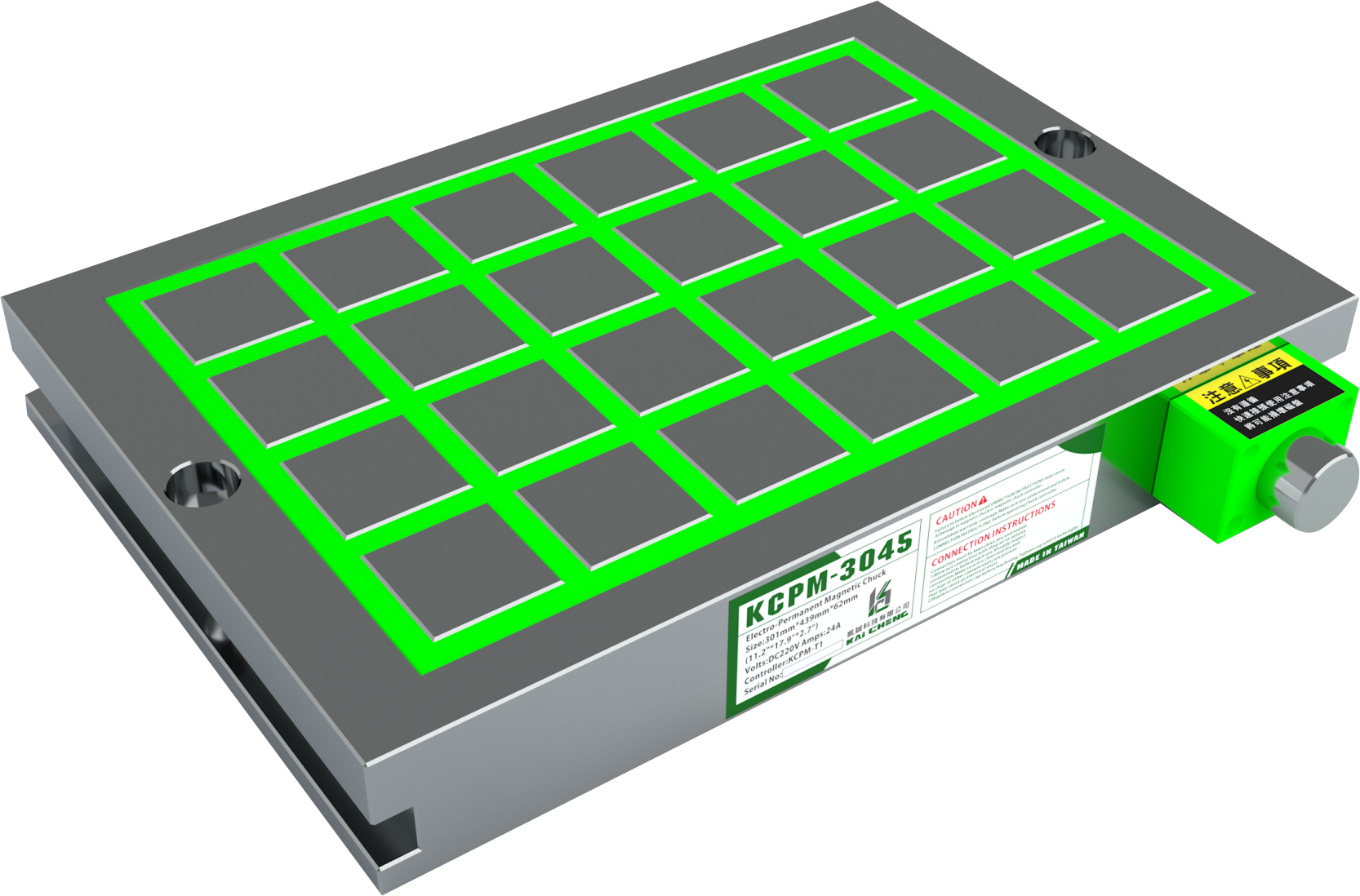

kai cheng co.,ltd

製品の説明 :

Features of the electro-permanent magnetic chuck:

1.Strong magnetic power, as high as 1300kgf/110mm2 ±5%. (4 magnetic poles)

2.Electro-permanent magnetic design; 1-2 seconds to magnetize/demagnetize, does not require constant power supply during usage, no temperature rise, fit for long-term use, precision will not be affected by deformations to the workpiece from rising temperatures.

3.Use in coordination with the soft magnetic clamp, the tools will be able to move freely when machining, five-sides machining, drilling, tapping, groove milling, molding can be completed all at once, which significantly increases work efficiency and reduces the repeated position tolerance to achieve the precision requirement.

4.Shortens the workpiece placement time, the clamping area can evenly cover the complete machining range, able to work on multiple workpieces at the same time, improves machining processing time.

5.Can carry out five-sides machining.