展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

FAIR FRIEND ENTERPRISE CO., LTD.

製品の説明 :

1. Improve tools life and cutting efficiency, especially ideal for particular process requirements of brittle or hard、 high-temperature superalloy and composite materials.

2. Increased precision and quality of the workpiece to achieve excellent cutting results. (smooth edge)

3. Perfected ultrasonic control technology for easy selection, automatic frequency, and power adjustment.

4. The strong chipping of chassis concentrates the chips into the path as ensures high efficiency.

5. Anti-scale cover + KEVLAR armor material, used in glasses, ceramics super hard metal processing which can preventing dust protection system effectively.。

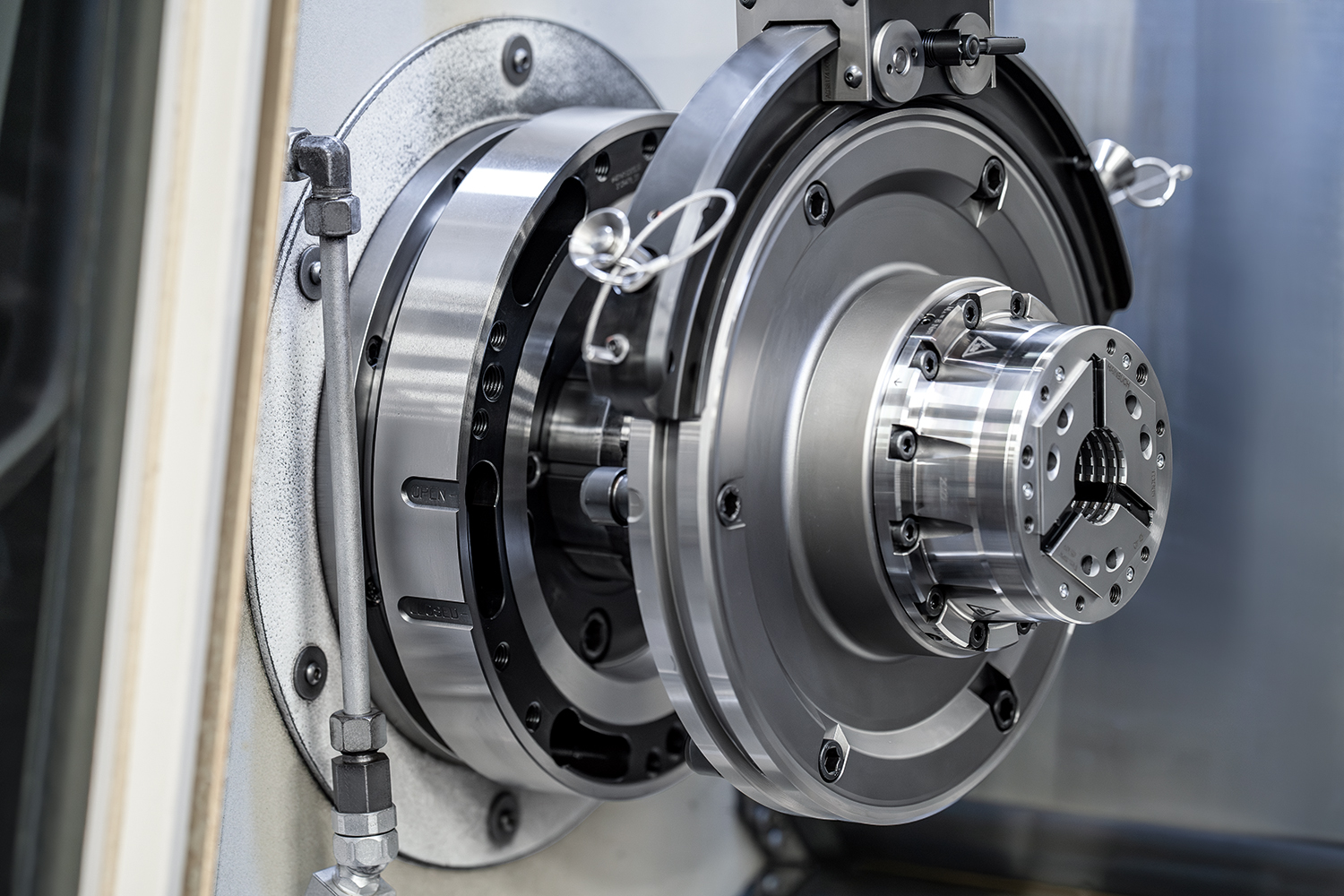

Hainbuch GMBH

製品の説明 :

The centroteX quick-change system from HAINBUCH drastically minimizes set-up times. Clamping devices can be changed in less than 5 minutes in the M version and in less than 2 minutes in the S version. The quick-change clamping device system consists of a machine adapter that is mounted on the spindle. The clamping device equipped with the adapter counterpart can be replaced with another one in just a few simple steps. The repeat accuracy is less than 0.003 mm at the interface. centroteX makes the user flexible in the use of clamping devices. They only need to be procured once and can then be used across different machines.

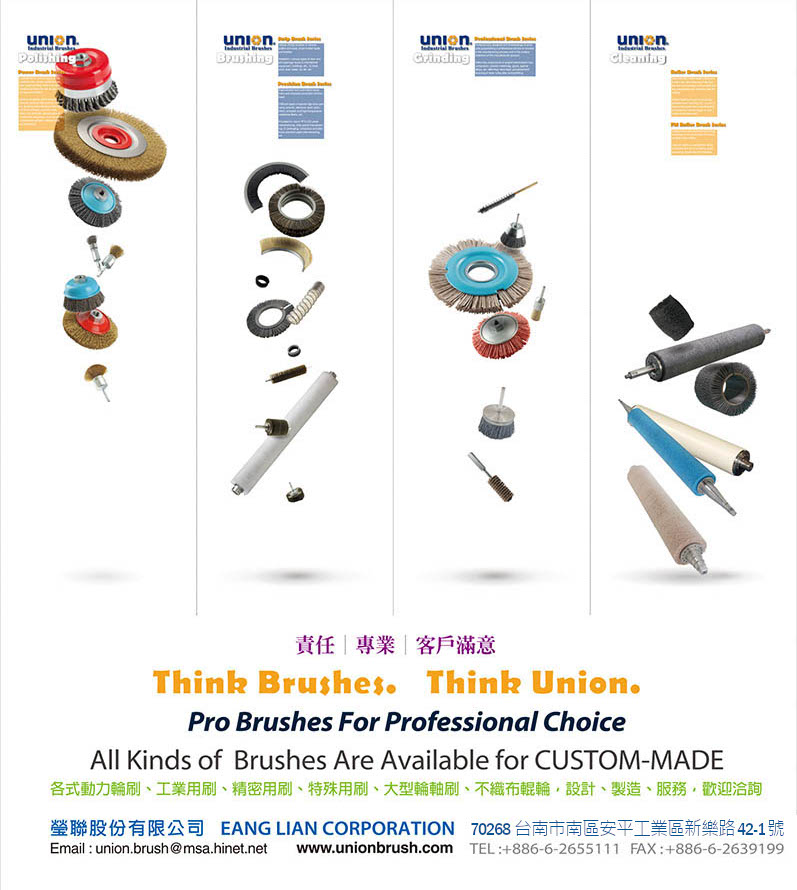

EANG LIAN CORPORATION

製品の説明 :

刷、磨、拋、洗<br />

專業化的設計能力<br />

多樣化的線材應用<br />

客制化的生產系統<br />

提供客戶製程製品-刷、磨、拋、洗.全方位的解決方案<br />

瑩聯股份有限公司—主要供應各式工業用刷是工業用刷之專業設計製造廠、擁有自有品牌(優利牌),產品適用於各行各業。無論需要刷洗、精細研磨、拋光、輕研磨、重研磨、毛邊去除、深孔加工皆有顯著效果!<br />

<br />

主要產品:<br />

1.動力輪刷系列適用於各型電動及汽動工具.<br />

2.矽砂尼龍研磨刷系列可針對各種表面精細研磨.<br />

3.輪軸刷及板槽刷系列接受各種線材及特殊尺寸訂製<br />

4.鋼鐵業退火酸洗、脫脂清洗、刷磨、清洗等大型刷輥<br />

5.德國技術合作專業生產高科技合成纖維輥適-用於鋼鐵軋片產線之刮油輥、塗油輥、擠水輥、張力輥、轉向輥、擠油輥、擠乾輥、擠壓輥、擠水輥、不織布擠水 輥。 6.各種線材及特殊尺寸可依照客戶需要量身訂製

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

SIEMENS LTD., TAICHUNG BRANCH OFFICE

製品の説明 :

Digital twins of machine tools

Digital twins of machine tools play a major part in optimizing the machine manufacturer's engineering processes. This is because the digital twin in the automation environment makes it possible to execute process steps in parallel, as opposed to consecutively, as used to be the case.

TAIWAN MACHINE TOOL CO., LTD.

製品の説明 :

Strong casting and the perfect boxway stucture provides excellent cutting capacity for TTB-20MW Series. Sub-spinfle with milling function and Y-axis can satisfy customers' miltiple needs.

-The one cast base incorporates FEM analysis to achieve its optimal ribbing and structure to further enhance machine rigidity and stability.

-The 30 degree slant bed design has low center of gravity for easier swarf management and better erogonomic design. The TTB-20MW Series also offer optional rear type chip conveyor.

-To make sure the usage life of Y-axis ballscrew will get longer, there are three bearing on Y-axis ballscrew to enhance the support for pressure from top.

-The TTB-20MW Series can achieve maximum 20m/min for X axis and 25m/min for X axis. And the servo motors adopt absolute encoders for faster and more reliable positioning.

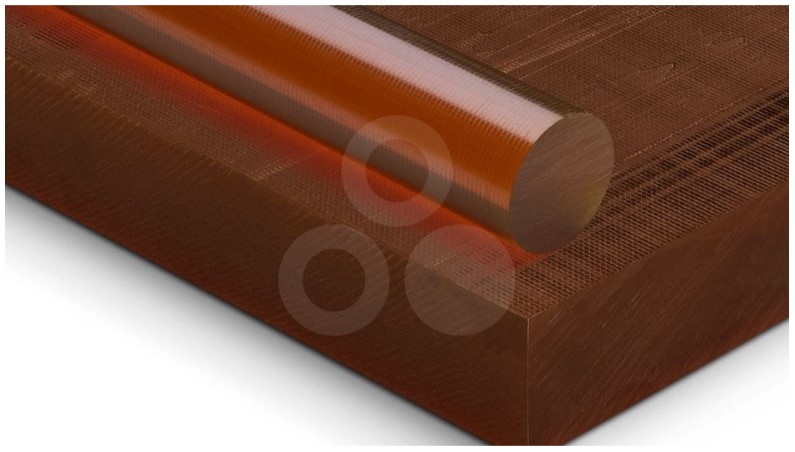

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

製品の説明 :

TECAPEI natural (PEI) is an unreinforced polyetherimide, suitable for contact with foods, that exhibits high mechanical strength and rigidity. The characteristic profile includes very good hydrolysis resistance, and dimensional stability, combined with a relatively high long term service temperature.