展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

EQP SERIES CO., LTD

製品の説明 :

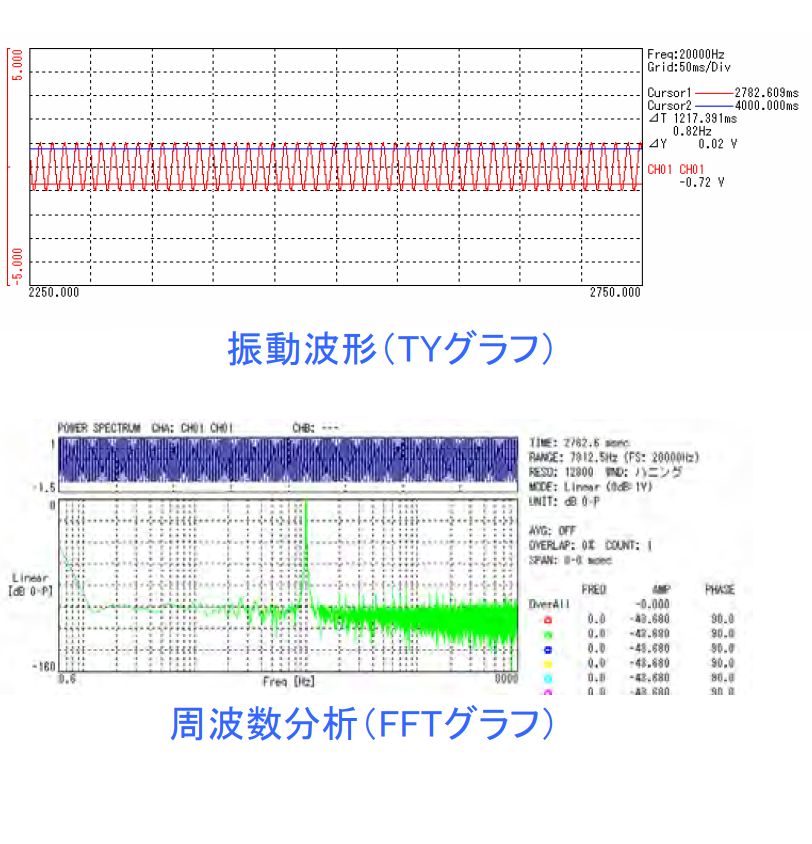

Connect various vibration meters for vibration analysis.

It is a waveform acquisition and analysis software capable of handling up to 32 channels.

It provides waveform (TY) graphs, FFT graphs, XY graphs.

Real-time or post-processing waveform analysis is possible.

You can add any filters or perform recalculations in post-processing.

It also allows for audio playback of waveform data.

Compatible with various types of vibration meters.

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

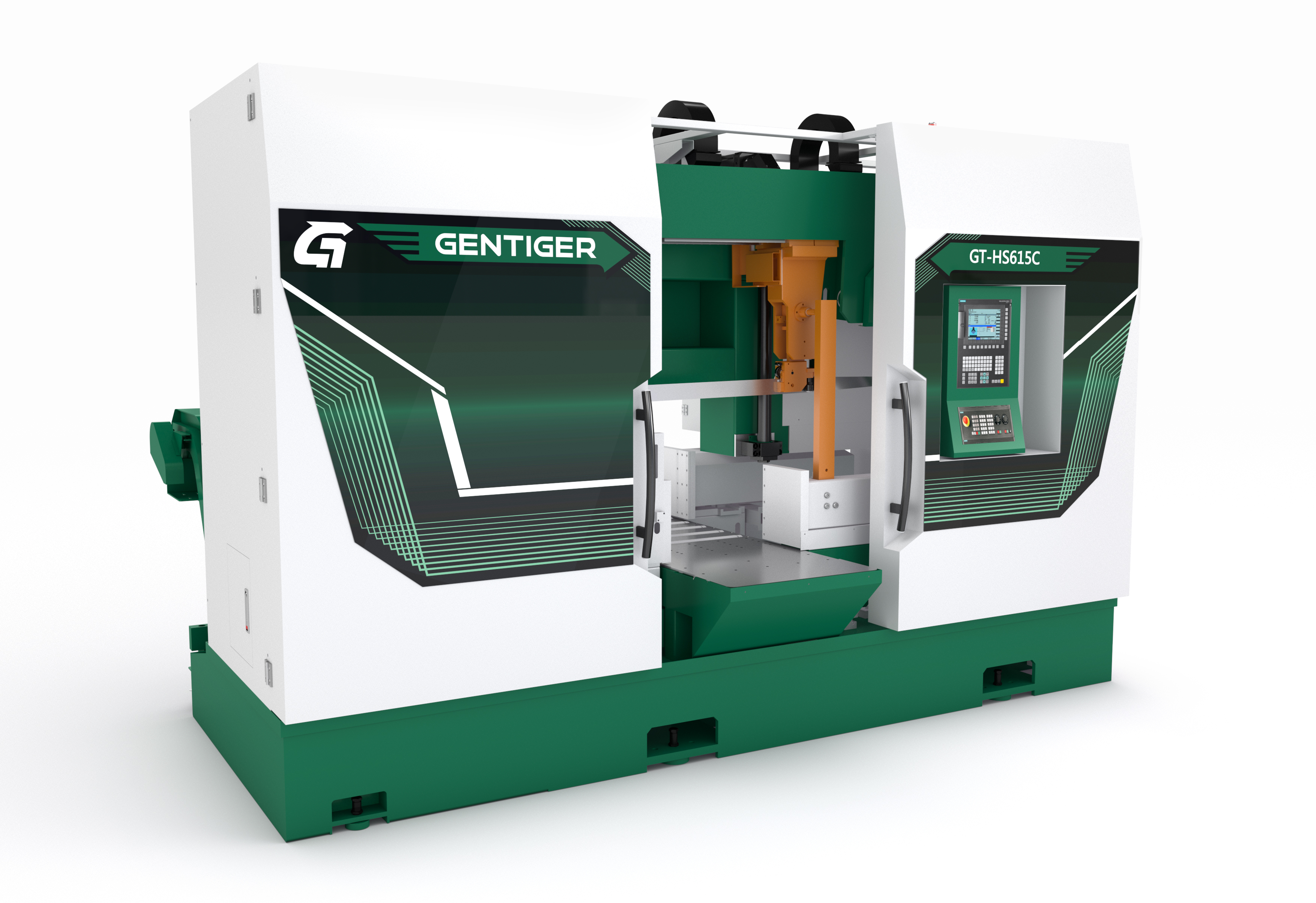

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. The double column saw frame structure raise rigidity.

2. The main driving wheels are equipped with an encoder for instant feedback and speed compensation.

3. Material sizing and cutting feed by servomotor.

4. The roller bed and dual movable jaw of F&R avoid material drag and squeezing.

5. The arch elevation mechanism uses a laser induction and isn’t limited by the material height and shape.

6. The sawing order can be scanned by QR CODE to establish the parameters and is beneficial for management.

7. Graphical dialogue operation screen, humanized operation, improving operation convenience.

8. Equipped with a multi-function meter that immediately monitors the instantaneous energy consumption and efficiency.

9. High-performance design and stable structure can get the best sawing flatness, reduce material waste and improve efficiency.

10. The machine combines fashion and technology while injecting the meaning of high speed, stability, and eco-friendly.

FOCUS CNC CO., LTD.

製品の説明 :

45 degree slant bed one piece casting the structure with low center of gravity, easy access and work-piece changeovers. Improved chip removal helps prevent thermal deformation. Powerful 4 stage spindle bear box provides 45kW horsepower available for large diameter work-piece and heavy duty cutting. Large through hole suits numerous bar sizes. Double row roller bearing increases stability and rigidity for heavy cutting.

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURE:

Compliant with IEC 61672-1 class 1 standard

Dynamic range of 90dB

AC and DC outputs

Data transfer using USB

microSD card

Real-time 1/1-Octave and 1/3-Octave analysis

Measurement can be started by internal or external trigger

Comparator output to trigger external devices

Super high – contrast backlight TFT – LCD color display

ECHAINTOOL PRECISION CO., LTD.

製品の説明 :

"鎢鋼鑽頭為益詮2020年全新上市主力產品,採用國外進口五軸刀具研磨機生產製造,研磨尺寸精準且穩定,提供高品質鎢鋼鑽頭服務。

產品特色:

(1)鎢鋼刀體為含鈷量12%超微粒硬質合金,高剛性耐磨耗耐高溫,可以加工切削HRC<55°工件(2)鑽尖結構加強優化設計,提升切削排屑性能(3)獨特雙刃帶設計,提升加工穩定性,可增加切削加工使用時間(4)全新AlTin鍍鈦塗層,泛用性廣可適用:合金鋼、不鏽鋼、鑄鐵加工。

益詮精密專業製造:(1)捨棄式車刀:新增中心出水外徑車刀架和中心出水內徑車刀架(2)捨棄式铣刀:新增捨棄式粗铣刀、捨棄式T形槽铣刀(3)捨棄式刀片:整合各式車刀片及铣刀片新材質開發(4)鎢鋼端铣刀:新增鎢鋼鑽頭,極小徑鎢鋼一體式車刀,開發新鎢鋼圓棒及特殊研磨刃口端铣刀。

為因應廣大市場需求,益詮精密持續開發精進新增所有刀具品項,不斷努力提升產品品質和服務,秉持初衷努力不懈進步成長,生產製造以最高品質要求,期盼能成為台灣製造業的後盾。"