展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

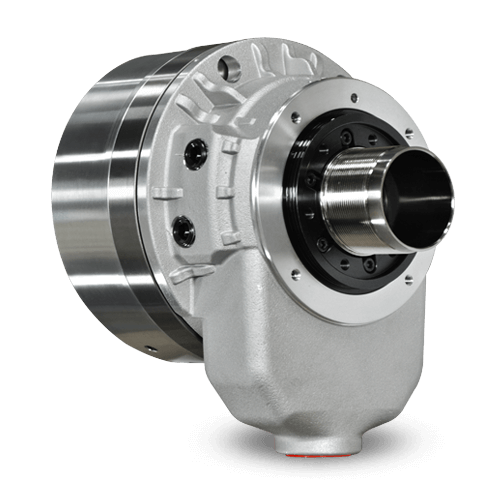

AUTOCLAWS PRECISION MACHINERY CO., LTD.

製品の説明 :

1.Through-hole design facilitates automation center feeding or long bar material processing convenience.

2. Safety Device: Whole series of our cylinders are equipped with check valve as the security device, furthermore, the back-lock design of the cylinder body can strengthen the structure rigidity and decrease the counter-force generated by thrust or pushing force, either the front-lock also can be applied to the cylinder body as well.

3.Short structure design: The short structure design will strengthen the structure,reduce the torque reaction and also decrease both the load of the spindle and the interference when assembling.

4.Light Weight: The cylinder made of high-intensity aluminum alloy and high-strength alloy steel, the structure design can lighten the weight and reduce the rotation inertial

effects,and not only strengthen the structure but also increase the cooling effect.

5.Durability: Adopting high quality steel alloy through hardening treatment and high accuracy professional grinding technology go with superior quality seals, the cylinder can achieve high intensity, high rigidity and well durability features.

A Being Kou Tools Co., Ltd.

製品の説明 :

MicroCentric was founded in 1969. 50 years of advancing engineering and high-quality manufacturing has earned MicroCentric the reputation as the global leader in precision workholding technology. Each MicroCentric product is backed by superior design, the highest quality materials and precision workmanship for reliable, long term performance and unmatched accuracy.

MicroCentric is renowned for building workholding products of unmatched precision and accuracy. Most MicroCentric’s precision chucks have a standard repeating accuracy of .0001″ (0.002mm), and many models are accurate to within .00005″ (0.001mm).

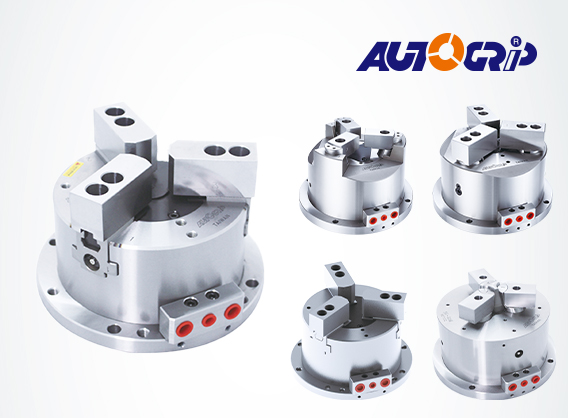

AUTOGRIP MACHINERY CO., LTD.

製品の説明 :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

HAINBUCH GmbH

製品の説明 :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.

HAINBUCH GmbH

製品の説明 :

The HAINBUCH SYSTEM allows you to clamp 1,000 different workpieces and gives you everything you need for complete machining.

You need only one basic clamping device – a chuck or a stationary chuck that remains on the machine. For O.D., I.D., jaw or magnetic clamping, or clamping between centers you then use adaptations – without having to accept any compromises.

The workpiece defines the adaptation and converts your basic clamping device for the particular application. This incredible solution reduces set-up time substantially, while increasing flexibility and making it possible to easily squeeze in short-term jobs.