Theme

Digital Transformation

Green Transformation

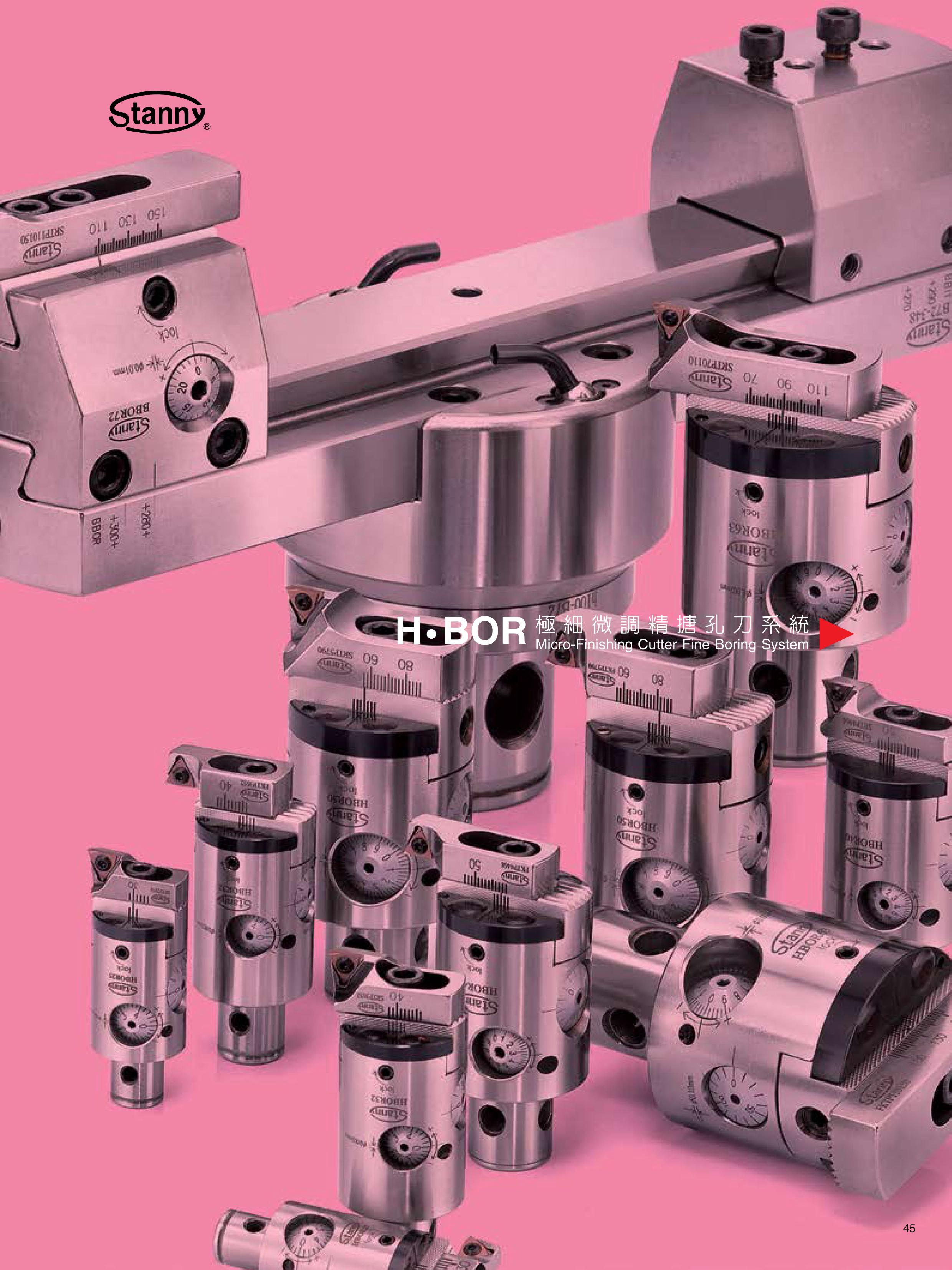

STANNY MACHINE TOOLS CO., LTD.

Product Description :

HBOR Micro-Finishing Cutter Fine Boring Sysetm, the boring range Ø2~Ø230, have SRTP,SRTC,SRCC,SR9C,FKTP,FKCC and FK9C-type cutting insert holder.

VISION WIDE TECH CO., LTD.

Product Description :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.

STAND TOOLS ENTERPRISE CO., LTD.

Product Description :

◎ Quickly and safely to clean up sharp cuts like iron & steel

chips and waste.

◎ Release iron filings by pulling the bar.

◎ Easy to pick and release scrap and ferrous debris.

◎ Light, non-rusting stainless steel shaft.

MANFORD MACHINERY CO., LTD.

Product Description :

高效率的主軸頭與排屑設計

主軸馬達選用低轉速高扭力伺服馬達,提供切削能力。

內部鈑金與底座為傾斜式設計,不易積屑,使排屑更順暢。

採後出式排屑,具有高容量排屑排屑系統,有助於加速切屑與切削液的排除。

機臺結構

- 機身採用米漢納鑄件,經過回火處理消除應力,以確保機台達到最

佳達最佳剛性與精度穩定性。

- 兩軸滑道採用高剛性、高精密的滾柱線性滑軌,具備高負荷、低噪

音與使用壽命長之特色。

- 標準配置為:8把刀之油壓刀塔。

- 刀塔選配為:伺服刀塔或動力刀塔。

JEFFER MACHINERY CO., LTD.

Product Description :

ASG-800 is an Automatic Carbide Saw Grinder. Original design idea and goal is by the user-friendly, clear operation panel, the PLC numerical control and stores up huge tooth patterns inside it. The machine could grind different kinds of TCT saw blades and can store up common tooth patterns up to 100 groups. It has automatic compensation program to set up grinding wheel compensation. It also can adjust grinding speed and has automatic lubrication system. This is a multi-purpose Automatic Carbide Saw Grinder.

ASG-800 Feature :

1. Using Servo dividing on grinding wheel angle is fast

with high accuracy.

2. It can adjust high and low speed on grinding wheel up

and down movement, which can save working time.

3. Servo used on fixing position for pushing tooth with

precise and fast orientation.

4. With automatically right-left moving on grinding wheel

while working, this can reduce grinding noise and can

sharpen knives well.

5. Grinding capacity : dia.120~800

Saw blade bore diameter: dia. 10~85

YA LIANG INDUSTRIAL CO., LTD.

Product Description :

S-TYPE Special heavy duty model #122

Extremely high accuracy and precision design, suitable for CNC machining and machining center. All parts are ground, heat treated, surface treated and under specific QC condition.

H-TYPE Heavy duty model #123

Industrial design especially for milling machines and drilling machines.

All hardened parts ensure long life and safety while in operation.

HYDROKOMP GmbH

Product Description :

Swing clamp cylinders release the clamping point on the workpiece. With this, it is easy to change the workpiece. This hydraulic swing clamp cylinder operates as single-acting or double-acting traction cylinder, whereas part of the stroke is used to rotate the piston. The model with 0° swing angle operates only vertical as traction cylinder.

To guarantee a long lifetime the cylinders have an integrated metal wiper as standard. For oil supply, the cylinders are equipped with threaded port and manifold port with O-ring for drilled channels. You can select between right or left turning models with various standardized swing angles. The integrated overload protection protects the swing mechanism from damage due blockage of the rotation or improper assembly of the clamping arm.

For any risk of exceeding the permitted volume flow a throttle check valve must be interposed into the oil supply line. Counter-hold the clamping arm when tightening or loosening the counter nut in order to prevent torque transfer to the piston rod and to avoid damage to the ball guide. Variations with 0°, 30°, 45°, 60° and 90° swing angles are available. The permitted operating pressure is depending from the clamping arm length.

CIMer Tech co.,Ltd.

Product Description :

Distributed data management

Store, protect and deliver your most important messages

CIMer is a system specially built for the period from product development to mass production. From business orders, CAD product design, material creation, process review, and project management, it can be tracked and searched through any device. As long as you have a browser, you can Can participate in inspection and review of product design and development work.

system structure

Each region establishes its own Vault Server, and files will be synchronized between Vault Servers. Users can access the local Vault Server when accessing files. Users do not need to obtain the original CAD drawing files. CIMer provides converted graphics viewing formats (3D HTML/2D PDF), which can reduce the consumption of web page resources during viewing and improve transmission efficiency....

project management

Provide dynamic information on multi-project management at each stage during product development, such as Gantt charts, to assist the product development team in focusing on product development and improvement, and provide relevant timetables, human resources, output overview and distribution development periods during the period. , achieve better planning and utilization.

Design data and graphics management

Multi-CAD integration platforms, including drawing configuration, properties, versions, version management, combined drawing structures, parts and specifications/file associations of AutoCAD, zwCAD, Creo, Solidworks, Solid EDGE, Inventor, ZW 3D, NX, CATIA, etc., such as Approving documents, document version management, HTML format model viewing, 2D PDF document viewing, sharing drawings, BOM information based on design combination drawings...

Material Management Parts BOM/EC

After the product drawing design is completed, it enters the engineering proofing stage and related material information collection and management. Drawing files, material number correspondence, material attribute management, version management, association and viewing of materials and files, material BOM, automatic generation of material numbers, shared materials, etc...

Sign-off process management

Provide process system customization, and allow multiple people to collaboratively review all work that requires mutual notification, recognition, and review during the product development process. It is used at the review and notification level of the process and can be flexibly applied to the work processes of different departments and personnel.

Network collaboration

CIMer Web provides data viewing in non-Windows environments and implements the basic principles of ESG. Any device with a browser can participate in online process progress, such as inspection and review of product design and development work, paperless factory, post-engineering EC design change management from direct access of design drawings to manufacturing cells...

Message Center

Similar to the Outlook mail management function, it provides a message management center to manage notification messages, quickly jump from messages to related project work, and at the same time send emails to the mail server...

Over 20 years of experience in CIMe system development.

Over 300 case studies.

Visited more than 1,000 customer needs.

More than 200 customer satisfaction cases.

The CIMer system helps shorten your product time to market and significantly saves production costs and hidden losses.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

CAMPRO develops a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. The T Series are focus on cutters which is able to adjust the width according to different cutter such as milling, drilling, end-mill, tapping and so on. The patented transmission system allows user to select and dispense, withdraw cutters easily. Available to augment cabinets, max. support 100 cabinets. (Disc Type Cabinet, Tools Holders Cabinet, Recycling Cabinet, Compartment Type Cabinet, and Drawer Type Cabinet)