Theme

Digital Transformation

Green Transformation

Giant Red-Wood Int’l & Co. Ltd

Product Description :

RW-600A Hydraulic Riveting Machine (Mitsubishi 10” HMI)

(Without Feeding System)

-Safety Device to protect finger get injured

-Proportional Value Control System

-Double-Pumps hydraulic Designed

-Auto-Riveted Counting to avoid missing riveted

-Mitsubishi 10” HMI

-Control System: Mitsubishi PLC

-Pressure Range:2-53KN(6T)

-Horsepower:3HP

-C type throat depth:450mm

-C types throat height:400mm

-Power Voltage:220V Three-Phase

*Mitsubishi 10” HMI can ensure the pressure during the operation. It also can auto-check for faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6 (Carbon Steel)

* Proportional Value Control System: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

*OMRON 5” HMI can ensure the pressure during the operation. It also can auto-check faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6( Carbon Steel)

*Pressure control easy to operate: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

HAI JU TRADING CO., LTD.

Product Description :

High-strength connection and maximum sealing

Can you imagine high-quality products without screw connections?

Modern technology cannot do without them as detachable joints. In the industrial

sector, fluid technology, pneumatics and sealing technology are among the fields of

application. In those sectors, often additional functions such as sealing, insulation or

reuse of bolts are required – only to mention a few.

One classic example are adjusting screws on hydraulic components, steering boxes

and fuel injection pumps. For those applications, high-strength screw connections

with reusable bolts and sealing against leakage are essential. We provide the solution

that fulfils those high requirements: the SEAL LOCK® sealing nut. It prevents any

unwanted leaking of gaseous or liquid media. The SEAL LOCK® ring integrated on

the nut helps to achieve reliable sealing inside the thread without the use of

additional elements. It is reliable in two ways because it seals under the head and

inside the thread. Not to mention the easy installation.

The following figures show conventional solutions on the one hand and the

SEAL LOCK® sealing nut on the other hand.

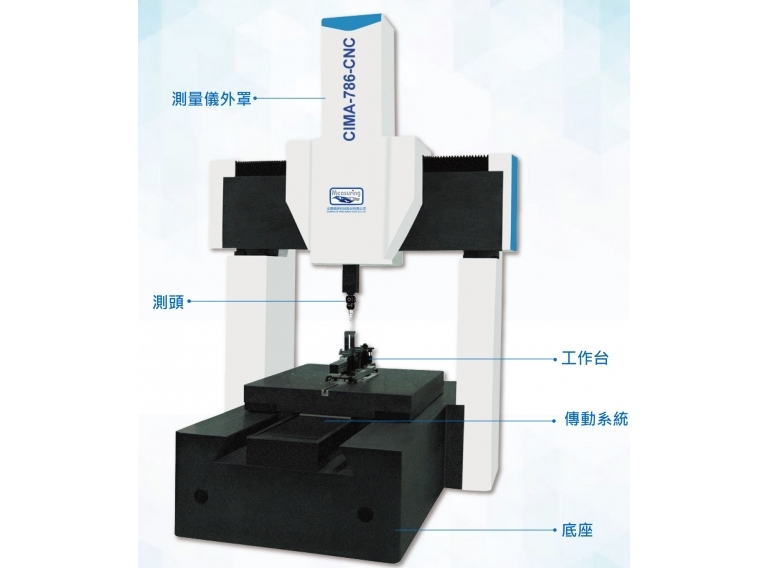

COMPLETE PRECISION TECH CO., LTD.

Product Description :

CIMA系列量測儀採用國際先進的有限元分析設計方法,使其具有機械結構剛性強、幾何誤差小,具有高精度、高性能和高穩定性的優點。機械整體結構採用剛性結構好、品質輕的全封閉框架移動橋式結構。其結構簡單、緊湊、承載能力大、運動性能好。固定優質花崗岩工作臺,使其具有承載能力強、裝卸空間寬闊、便捷。<br />

Y向導軌採用燕尾式,定位精度高,穩定性能好。 三軸採用優質花崗岩,熱膨脹係數小,三軸具有相同的溫度特性,因而具有良好的溫度穩定性、抗實效變形能力,剛性好、動態幾何誤差變形小。<br />

三軸均採用自潔式預載荷高精度空氣軸承組成的靜壓氣浮式導軌,軸承跨距大,抗角擺能力強,阻力小、無磨損、運動更平穩。<br />

橫樑採用精密斜梁設計技術,重量輕、重心低、剛性強,動態誤差小,確保了機器的穩定。<br />

PRAISE PRECISION IND. CO., LTD.

Product Description :

Products name: Rotary Broaching Tools

Model Number: BCM22-ST16

Features:The ADONAI broaching tools is simple, easy to operate attachment, which produces regular or irregular polygons in blind or through holes having sharp or chamfered edges. The attachment operates with a hunting rotary motion which, in addition to the standard hexagonal and square holes, can also produce grooves, Torxs and other special profiles.

The ADONAI broaching tools can also be used on lathes, CNC automatic lathes, machining centers, drilling machines and special purpose machines for wide variety of standard or special internal and external forms.

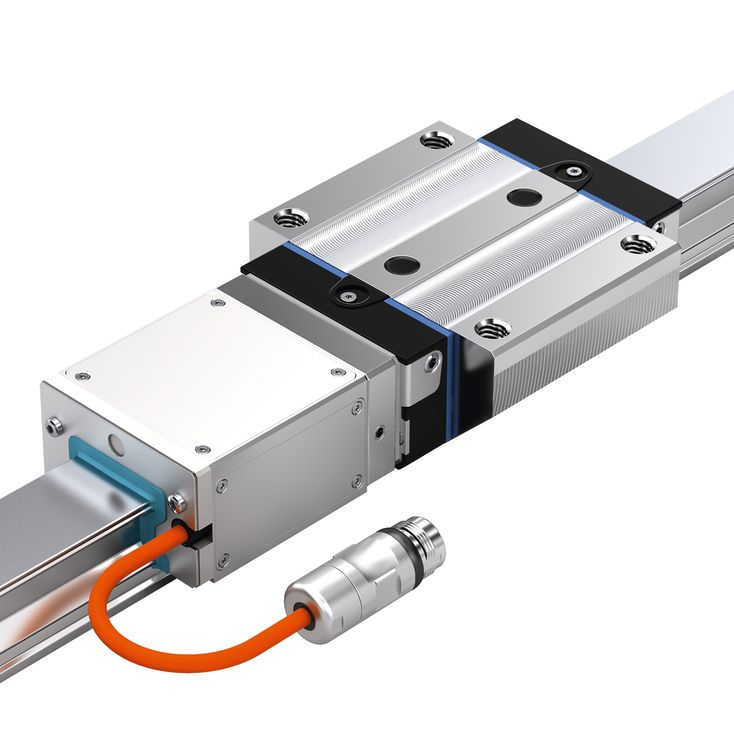

JASON AUTOMATION CO., LTD.

Product Description :

Our linear components and systems are precisely developed and produced, and provide the basis for you to manufacture best-in-class machines and automation systems. The high quality and long life of our Linear Motion Technology guarantees you maximum system availability. With over 1000 standard components and products and our modular principle, we can always create an individual solution for you. As a leading user and supplier of Industry 4.0, we ensure that you are also ready for the future. We support our users reliably throughout the entire product life cycle, beginning with finding the right solution, to consulting and eTools, all the way to worldwide, on-site service.

EQP SERIES CO., LTD

Product Description :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. High rigidity body structure, machine base casting is integrally formed and high rigidity linear guide way, providing stabler, faster and higher precision.

2. Built-in main spindle is with C-axis function, high speed, big power, high precision and low vibration which can make surface of workpiece smoother.

3. Optional:Synchronous rotary guide bushing device, it's suitable for processing long workpiece which can reduce cycle processing time and improve production efficiency.

4. Sub-spindle is with C-axis function, it can work with live tooling for end side drilling, tapping and milling.

5. It can depend on different demand of machining to with or without Synchronous rotary guide bushing device.

6. Axes:Z1/X1/Y/C1/Z2/X2/C2 + 3 sets of live tooling devices (A/B1/B2)

7. Max. 23 tools, can do machining on front side and back side at the same time which can save time for processing.

8. With guide bush type travel is 180mm, min. offal is 150mm. Without guide bush type travel is 310mm, min. offal is 50mm.