Theme

Digital Transformation

Green Transformation

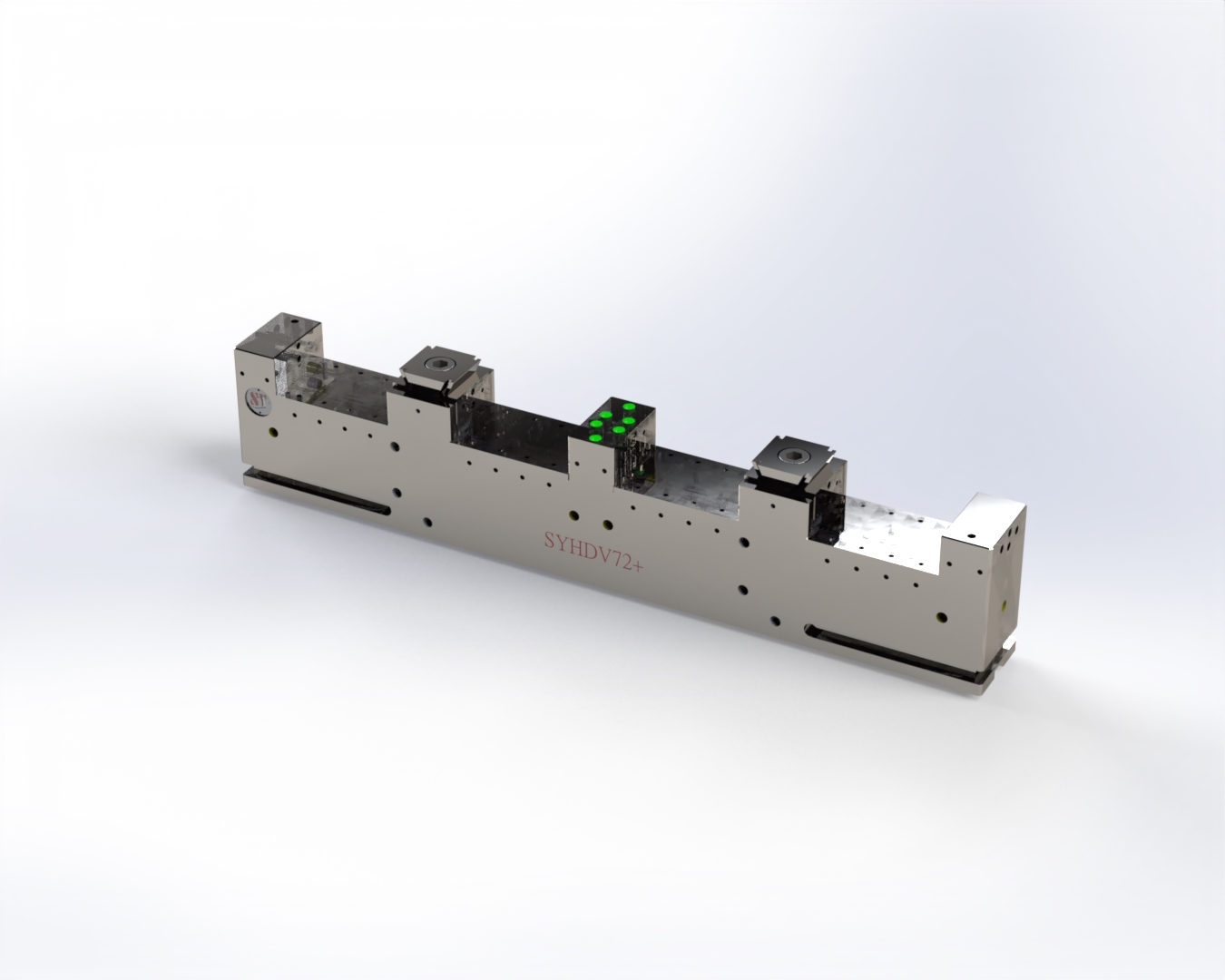

AUTOCLAWS PRECISION MACHINERY CO., LTD.

Product Description :

1.Push type collect chuck fixtures can perform high accuracy of axial position locating by the components and mechanical structure design.

2.The collect chuck could be installed onto the lathe machines rapidly and easily without changing the pulling-pipe when it is switched with the exist chuck.

3.Quick-dismantling design: The front cover can be quickly removed

Simply replace the elastic clip can be replaced to immediately turn different sizes or shapes (round, square, hexagonal...) for increased efficiency and versatility.

4.The components through special technology of hardening treatment to archive high intensity,high rigidity and well durability.

5.Professional precision grinding makes it high-precision, precision repeat clamping accuracy.

WEXTEN PRECISE INDUSTRIES CO., LTD.

Product Description :

■Single refrigerant circuit is with multiple oil circuits, and it provides independent flow rate and pressure precisely.

■ Different liquids can be controlled temperature at the same time,and it can be customized.

■ Temperature control of Dual-PCB for each of plural circuits and it can adjust temperature individually.

■ It has temperature compensation and preheated function.

■ Temperature control precision is +0.5~1.5 ㆍC. (It can be customized of other temperature control precision.)

■ Saving about 50% of floor space.

■ Using high-efficiency environmental refrigerant and without pollution.

■ Up-to 95% materials of machine are recyclable and eco-friendly.

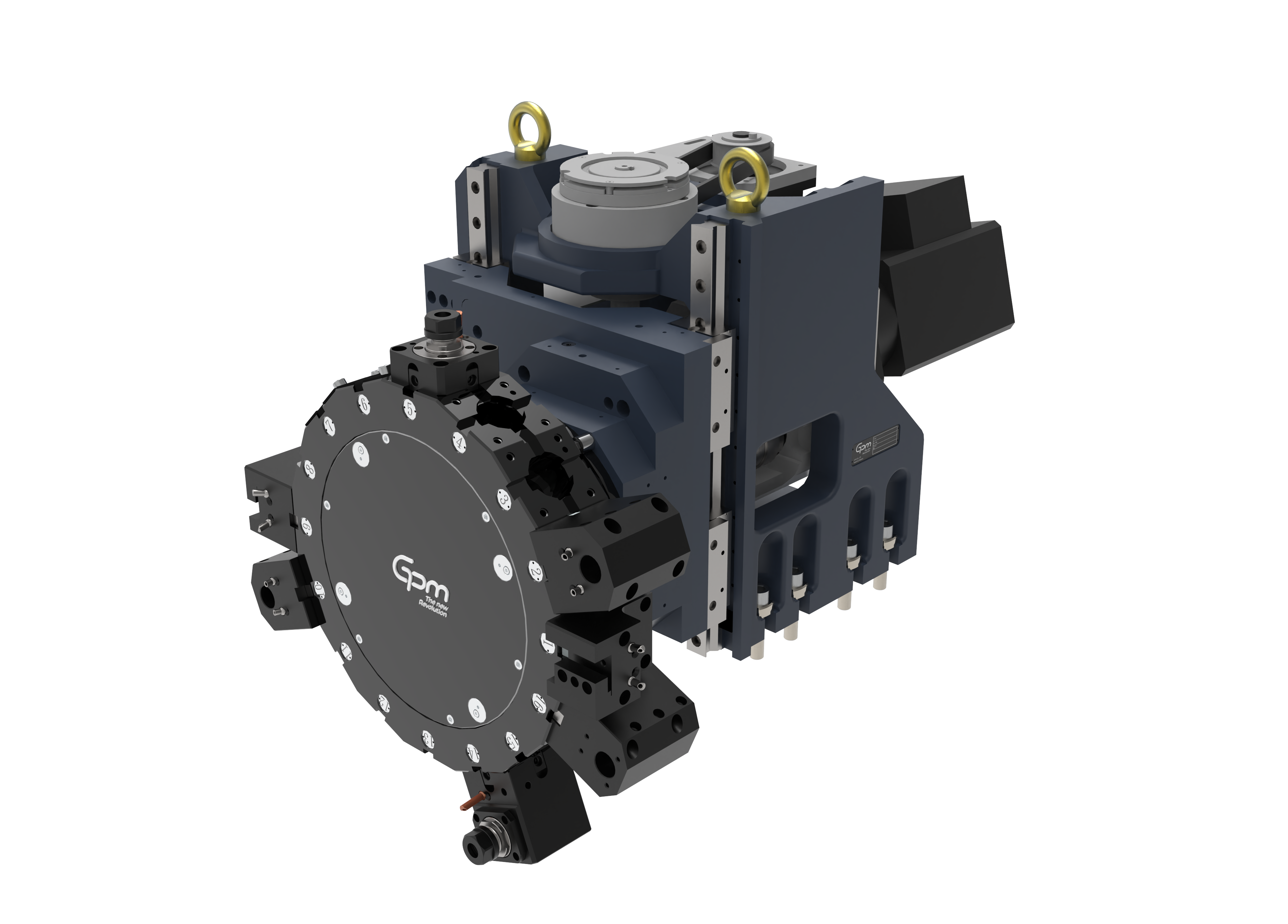

GPM CO.,LTD.

Product Description :

● External mount type:

■ Suitable for single/two spindles machines

■ 2 linear guide/1 ball screw design

■ Y axis travel: ±50~60mm

■ Y axis equipped with electromagnetic brake.

■ Additional motor brake is possible.

● Central mount type:

■ 4 linear guide center-mounted screw design.

■ Interference is reduced by about 30%.

■ Suitable for high-complex processing.

■ Applicable for medium~light cutting.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

1. The structure design highlights the stability during high-speed processing.

2. The base design provides multi-angle processing and improves support strength.

3. The tool length measurement device is designed inside the ATC door to avoid contamination.

4. Equipped with high-precision DD motor rotary table.

5. Sheet-metal integration reduces assembly time.

6. Internal bevel design to avoid chip residue.

7. Multi-window device improves operation convenience.

8. Could be equipped with automation/remote monitoring to improve production efficiency.

9. Ergonomically designed to reduce operator fatigue and improve safety.

10. Small footprint improves equipment utilization.

11. High Speed, stability, and precision provide a competitive edge in precision mold and die machining.

MONGTEC PRECISION INC.

Product Description :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

REAL TERN INDUSTRIAL CO., LTD.

Product Description :

The plate heat exchanger gives an excellent heat exchange capability. It replaces traditional evaporator and condenser. It is utilized in industries such as freezer and industrial controlling. The plate heat exchanger is small at size, light at weight and less power consumption.

EQP SERIES CO., LTD

Product Description :

This system is versatile and can be used not only for general vibration monitoring but also for measurements in challenging environments and is compatible with intrinsic safety and explosion-proof requirements. The Vibrating Converter MODEL-2503 is a system that can accommodate various sensors and specifications.

A vibration monitoring system using the Intrinsic Safety Explosion-proof Detector MODEL-2450EX is composed of detectors, barriers (safety retainers), and MODEL-2503 installed in hazardous locations.

The output includes not only DC4-20mA but also two systems of vibrating waveform AC±2V. This allows not only observation on digital monitors but also connectivity to various PLCs, contributing to the IoT compatibility of facilities.

Can be used in conjunction with the high-sensitivity piezoelectric accelerometer MODEL2430.

HABOR PRECISION INC.

Product Description :

> Applications

CNC Machining Center、CNC Grinding machine、Broaching machine、CNC Wood-working 、Machine、CNC Mechanical Press、CNC Lathe、High Speed Lathe

Hydraulic Unit

High Speed Spindle

> Feature

Prevent temperature increasing of spindle, improve working precision of machine.

Prevent deviation of spindle center line or heat deformation of machine.

Extend the lifetime of the machine.

Stabilize oil pressure, prevent oil vibration.

Easy operation, low noise.

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Product Description :

The brand-new product CNC Vertical Complex Grinding Machine SVG-E800 (SVG series), suitable for composite grinding of inner and outer diameters and end faces of various big cylindrical workpieces. Its mechanical structure adopts a double column type design, featuring high rigidity, high precision, high stability, and high efficiency. It is encased in aesthetically pleasing fully enclosed safety covers, and can be equipped with controllers from Fanuc, Mitsubishi, or the latest generation. With its conversational interface, operation is intuitive and easy. The grinding wheel spindle system is HSK-A100, 10000rpm, 18.5/15kw, capable of automatically changing wheel holders, with an ATC device capacity of 6 tools, and a spindle angle positioning system at 0 degrees/22.5 degrees, enabling various grinding processes with just one clamping. The workpiece spindle adopts a hydrostatic system turntable with a diameter of 800mm, maintaining axial movement accuracy <1μm. Models with turntable diameters of 600mm and 1200mm are also available. For further technical specifications, please contact the Sales Department of SIGMA CNC.