Theme

Digital Transformation

Green Transformation

REAL TERN INDUSTRIAL CO., LTD.

Product Description :

【Custom Product】

OEM ODM|WE FOLLOW YOUR REQUIREMENT!

【Technical Evaluation】

Special heat exchange project service

KING NICE TECH.CO., LTD.

Product Description :

▎Use Value reduce the CNC machine failure rate , processing non-performing rate.

▎Water and Coolant Saving.

▎Reduce the cost of CNC mechanical downtime and personnel operations.

▎Maintain the tank liquid caoacity , reduce the temperature rise.

LEEKA INDUSTRIAL CO., LTD.

Product Description :

LEEKA manufactures all kinds of leveling feet and heavy duty wheels. Our product category included leveling legs, adjustable leveling feet, industrial caster wheels and leveling casters.

Commonly used in industrial cabinets, transportation, compressors, generators, food industry equipment and so on. All products can be customized according to customer demand for different sizes, specifications and materials.

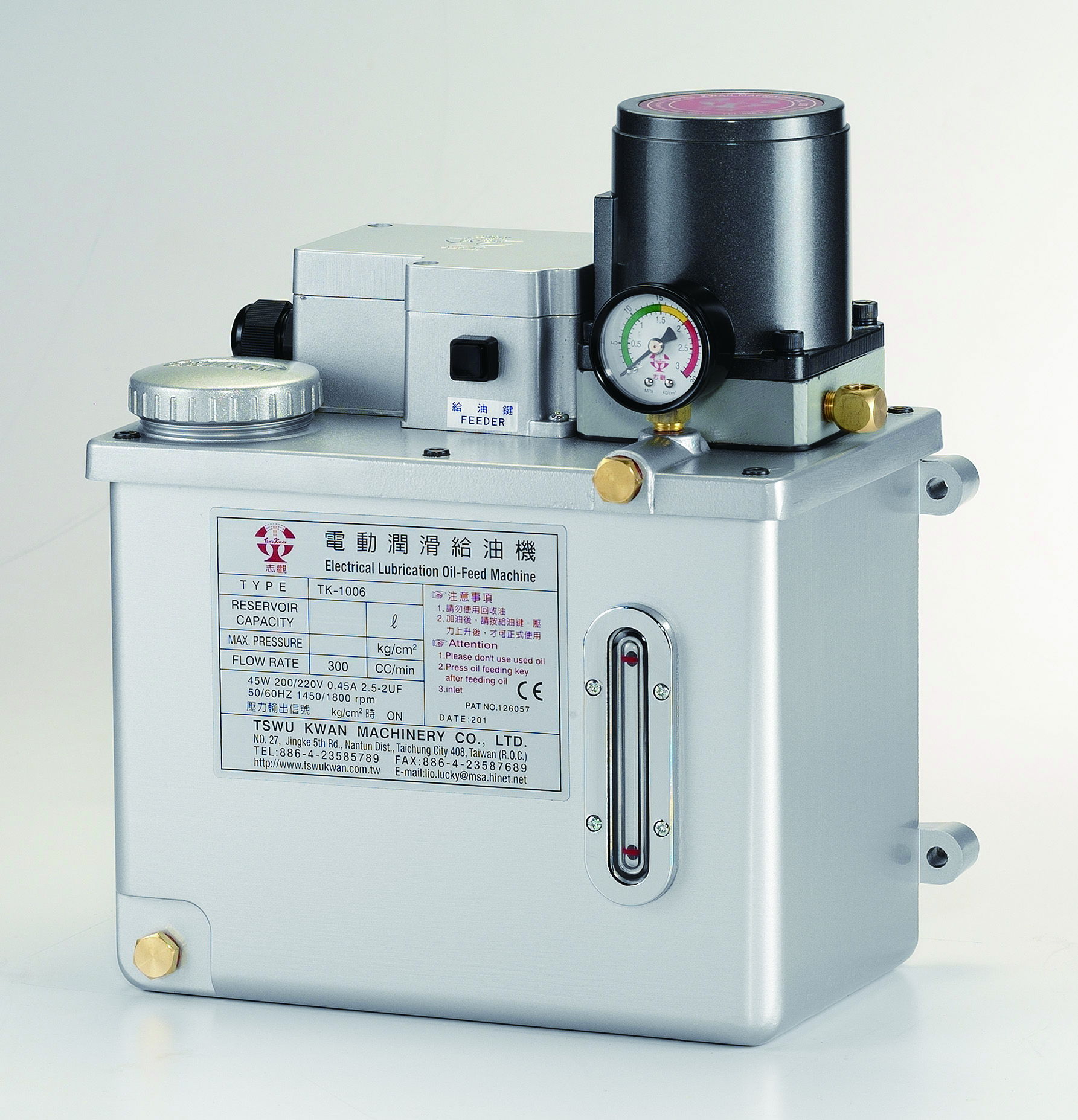

TSWU KWAN MACHINERY CO., LTD.

Product Description :

機械潤滑用-

以操作容易為設計原則,採用特殊內外齒輪,耐磨傳動雜音小、吸油力強,並設有定壓保護裝置,可配合機械之整體設計,有效應用於各種機械結構的潤滑點,並可發揮強制給油之功能。

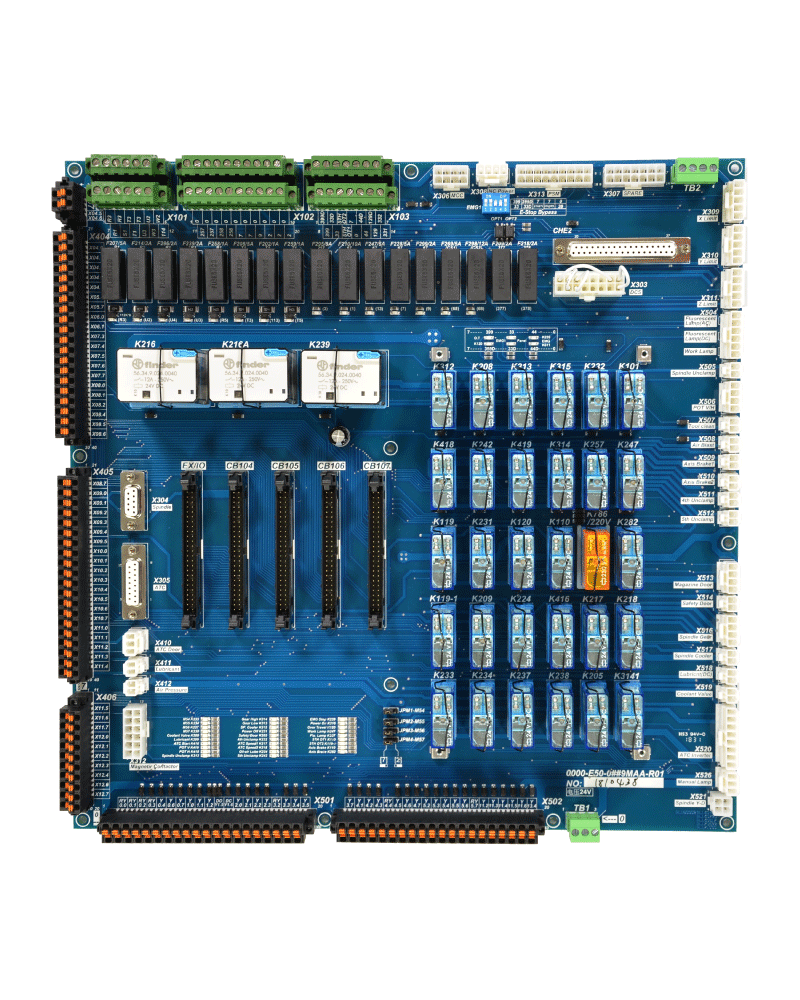

YEU-LIAN ELECTRONICS CO., LTD.

Product Description :

OEM/ODM circuit board combined adapter board, relay board, patch board and I/O board into one piece - all optimized to customers' needs. The PCB circuit board can customize various controllers such as FANUC, MITSUBISHI, SIEMENS, FAGOR, HEIDENHAIN and industrial types. Apply to CNC machines like lathes, milling machines, turning, multitasking machines, machine tools or industrial machinery.

SHENG FENG TECHNOLOGY CO.,LTD

Product Description :

Cross roller bearings consist of inner rings, outer rings, spacer retainers and cylindrical rollers cross arranged on the V-shaped 90° groove between the inner and outer rings. This structure can withstand radial, axial and moment loads in all directions because the rollers'line contact with raceway surfaces achieve a large load-bearing area despite the minimum dimensions. Therefore these bearings are widely used on the rotating parts of industrial robots, machine tools, precision rotary tables, measuring instruments and IC manufacturing machines.

Cross Roller Bearing Features:

High rigidity

Large load capacity

High rotation accuracy

Compactness

Easy to install and handle

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

For 34.1mm-52mm Twist Drill Re-sharpening , Angle 118°-140°

Precise Grinding Results , Precision Assurance within 0.1mm

Easy to Operate , grinding a drill within 10 seconds.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

Clamptek’s CLF5H series designed with connecting rod structure which can operate conveniently. CLF5H series can also reduce the interference with loading and unloading operation, because when CLF5H series is in the unclamping state, it’s clamping arm can be put lower than holding position.

Clamptek’s CLF5H series’ clamping arm is very flexible. By reducing the interference of the surrounding equipment, CLF5H series can save lots of working space.

Clamptek’s CLF5H series equipped with special dust proof design and high sealing, which can prevent the cutting chips and coolant to infiltration. Therefore, CLF5H series can be used in more severe conditions.

Please kindly check the suggested operating pressure as below,

Max. operating pressure: 70 kgf/cm2

Min. operating pressure: 10 kgf/cm2

FUTECH PRECISION CO.,LTD.

Product Description :

FUL series CNC Lathe is to enhance high speed and high accuracy. 45 degree slant bed construction features high rigidity and high stability.

X、Z axis are mounted with ball type linear guide ways or box guide ways. Axis movement is directly driven by a servo motor , allowing the high rapid traverse rates on X、Z axis.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.