Theme

Digital Transformation

Green Transformation

A Being Kou Tools Co., Ltd.

Product Description :

MicroCentric was founded in 1969. 50 years of advancing engineering and high-quality manufacturing has earned MicroCentric the reputation as the global leader in precision workholding technology. Each MicroCentric product is backed by superior design, the highest quality materials and precision workmanship for reliable, long term performance and unmatched accuracy.

MicroCentric is renowned for building workholding products of unmatched precision and accuracy. Most MicroCentric’s precision chucks have a standard repeating accuracy of .0001″ (0.002mm), and many models are accurate to within .00005″ (0.001mm).

HUI BAO ENTERPRISE CO.,LTD

Product Description :

1. Different length nozzles for different purpose.

2. Aluminum body light weight and durable.

3. Maximum flow for easy clean-up and blow off even the heaviest shavings and chips.

4. Meets or exceeds OSHA regulations.

CITY TOOLS CO., LTD.

Product Description :

可接受客戶訂作各式刀具。<br />

可依客戶需求條件定製,鍍層、刃數、螺旋角度、刃長、總長等不同規格專屬製作。<br />

可接受重切削不等分割客製化、重切削不等螺旋客製化。<br />

提供六刃、深溝、短刃設計。<br />

客製刀具系列無保留庫存,依訂單生產製作。

PHASIC CORPORATION

Product Description :

1.Developed on the dust collecting.Less air pollution when using the machine.

2.Supper bright LED light.

3.Wrist rest design can be comfortable for long time working.

4.Use the magnifier for colser work.It flips up when not needed.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

XYZ axes travel: 600x400x400mm (23.62"x15.74"x15.74")

W axis travel: 450mm (17.71")

Work table: 650x450mm(25.59"x17.71")

Max. Workpiece: 900x500x300mm(35.43"x19.68"x11.81")

Max. Workpiece weight: 700kg

Distance from table to guide plate:25~425mm(0.98"x16.73")

Machine dimensions: 1580x1250x2740(62.2"x49.21"x107.87")

Machine net weight: 1200kg

Electrode diameter: 0.2~3.0mm

Dielectric fluid: pure water ( dielectric oil for 0.2mm or below)

Filtration: Paper filter

Controlling axes XYZW

Monitor: 15” LCD screen

Input/output unit: LAN/USB

Min. Setting Unit: 0.001mm

Min. Moving Unit: 0.001mm

Graphical display: 2D

Machine Features

1. This system utilizes Windows CE controller.

2. Able to store data through USB and internet.

3. Dialogue window, along with picture description functions.

4. Touchscreen type interface.

5. Special repaired frames to quicken the maintenance speed.

6. Close-Loop design of digital feedback on three axis of the machine, significantly increases positioning accuracy.

7. Possessing good and simple operation interfaces

Common function keys are located on the operation panel for direct use, hot key function on screen for quick access.

8. ATC (automatic tool changer) and AGC(automatic guide chnger) can be installed

9. Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to search.

10. Automatic origin search and multi-point coordinate memory capability.

11. Chinese/English versions, Metric/British system switch and quick up, quick down, and slow up and slow down capabilities, resolution can reach 1um.

12. All alarms describe the source, data and exact time of problem occurrence.

13. Able to proceed standard GM code and extra GM code

14. Able to proceed DXF file transfer to position coordinate function

15. AB axis rotate table can be installed

16. Position simulation and work route can be displayed

17. During discharge change new electrode can automatically compensate depth

18. Backlash point automatic compensate function

19. Able to do single hole drilling, multiple hole drilling and multi thickness drilling

20. Blindhole drilling function, any depth can be set

21. Initial current can set to reduced value, which can prevent workjob surface damage

22. Initial polarity reverse function, can prevent uneven electrode caused efficiency decrease

23. Six axis linear interoperate accelerate speed movement

24. Input, output, various of machine status real time display system

25. Discharge program and parameter conversion function

Accessories

《 Standard Accessories for High-speed Drilling CNC EDM 》

Tool Box*1

Brass Electrode 1.0mm*10

Electrode Guide 1.0mm*1

Standard Chuck*1

Foot Pads*1 set

Filter*1

Rubber Seal*10

Halogen Work Lamp*1

Flushing Unit*1 set

《 Optional Accessories for High-speed Drilling CNC EDM 》

ATC

Electrode Guide(Other diameters)

Brass Electrode(Other diameters)

ER Type Chuck for electrodes up to 6mm

Submerged Work Tank

75Amp Power upgrade

Filtration System with Resin Bottle

A,B Axes

Automatic guide changer 3/6

JIN TAIRY ELECTRIC CO., LTD.

Product Description :

The source of PM2.5 is the two major emissions from vehicles and factories. PM2.5 is almost equivalent to the overall air pollution. Juntai Electronics has focused on industrial air pollution control in recent years, and has continuously developed innovative "oil mist air purifier" series, subverting the traditional thinking of oil mist machine operation, with unique outstanding efficacy and performance, using a unique centrifugal principle, lasting efficacy Constant, eliminating the cost of replacement of consumable materials and labor maintenance costs, compared to the same level model, it can save up to 20% of driving power, high efficiency and energy saving, regardless of appearance, design and performance, are the best in the industry.

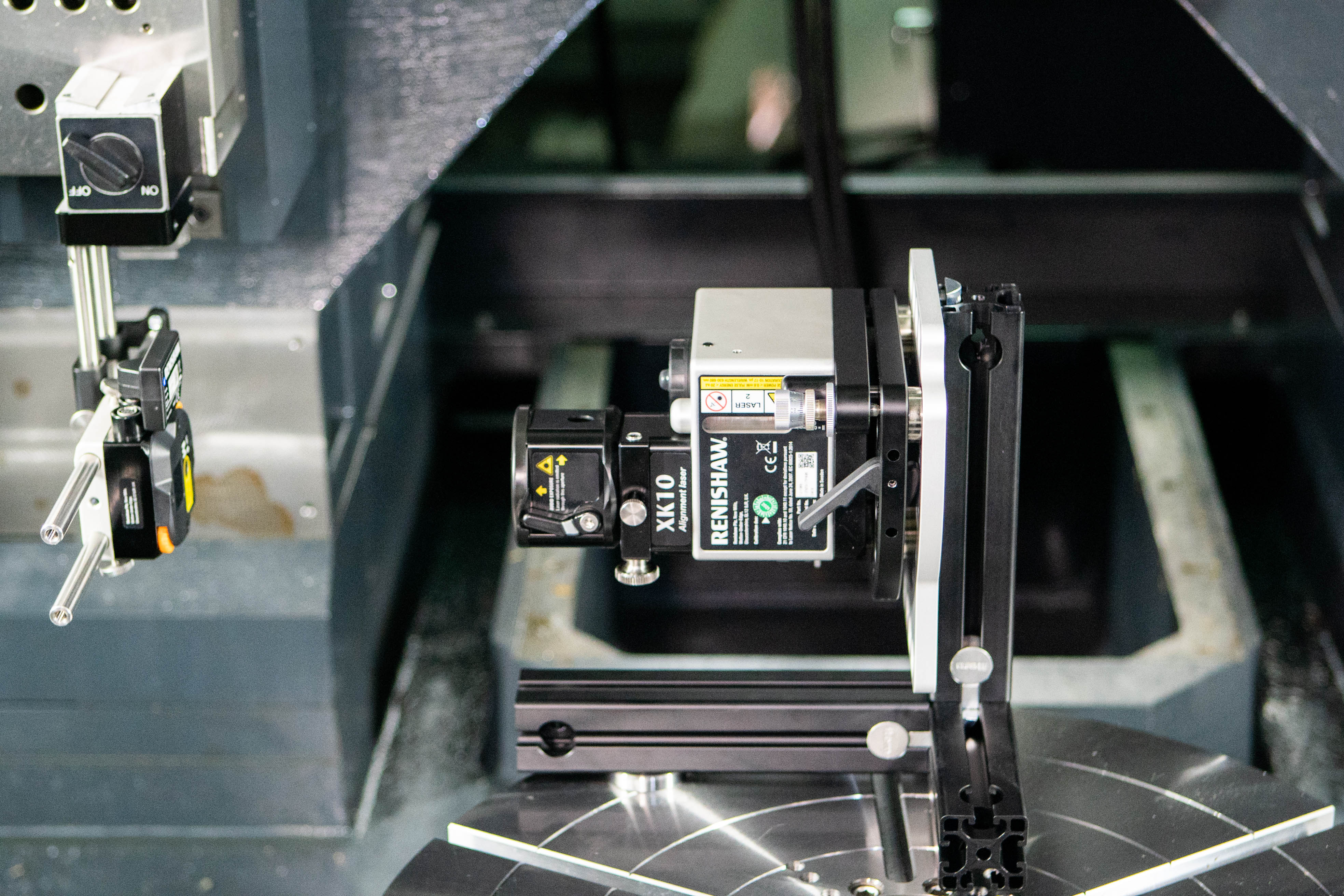

RENISHAW (TAIWAN) INC.

Product Description :

XK10 校準雷射系統是為了量測工具機的幾何和旋轉誤差而開發。與 XK10 工具機夾具套件搭配使用,能以比量錶、自動視準儀、量測治具等傳統方法更快、更簡單的方式進行量測。此系統可用於線性導軌,以確保導軌筆直、方正、平整、平行及水平,並可用於評估旋轉機器的主軸方向及同軸度。

HYDROKOMP GmbH

Product Description :

Swing clamp cylinders release the clamping point on the workpiece. With this, it is easy to change the workpiece. This hydraulic swing clamp cylinder operates as single-acting or double-acting traction cylinder, whereas part of the stroke is used to rotate the piston. The model with 0° swing angle operates only vertical as traction cylinder.

To guarantee a long lifetime the cylinders have an integrated metal wiper as standard. For oil supply, the cylinders are equipped with threaded port and manifold port with O-ring for drilled channels. You can select between right or left turning models with various standardized swing angles. The integrated overload protection protects the swing mechanism from damage due blockage of the rotation or improper assembly of the clamping arm.

For any risk of exceeding the permitted volume flow a throttle check valve must be interposed into the oil supply line. Counter-hold the clamping arm when tightening or loosening the counter nut in order to prevent torque transfer to the piston rod and to avoid damage to the ball guide. Variations with 0°, 30°, 45°, 60° and 90° swing angles are available. The permitted operating pressure is depending from the clamping arm length.

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI