Theme

Digital Transformation

Green Transformation

NUMEN MACHINERY CO., LTD.

Product Description :

Delta 6 is designed for new dimensions in precision, contour accuracy, surface quality and productivity. Maximum dynamics, precision performance milling and HSC machining are accurately executed. Offering wide range of applications including electronic watch, optical, medical and die mold.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

HYPERMAX MACHINERY CO., LTD.

Product Description :

1μ control-setting system and a design of high-rigidity roller rail track enhance the precision of locating axis. Also, JG1 integrates multiple processes, one chucking then inner face, bore and end face, into full grinding processes. Its powerful working capability completes a serial of 8 procedures at one time.

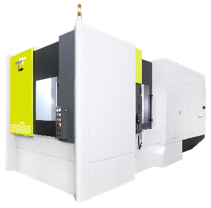

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

‧HTT-500, the 5-axis horizontal machining center, is Tongtai's new solution of process integration which will definitely meet the demands on high-mix low-volume manufacturing.

‧Excellent machine rigidity and stability to ensure high accuracy during precision machining.

‧Orthogonal mechanical coordinate system for easy programming and enhance the precision and efficiency of machining.

‧Central chip removal system effectively prevents the problem of internal temperature rise from accumulated cutting chips and reduces the environmental variables for higher precision.

‧Equipped with APC (auto pallet changer) system to shorten the machine idle time.

‧Built-in thermal compensation function to ensure ideal machining accuracy under different temperature conditions.

Administration for Digital Industries, moda

Product Description :

AEAPLUS Smart Factory empowers you to create the ultimate production workflow!

Highlights include:

MES System: Intelligently manage production for enhanced efficiency!

B2B Solutions: Simplify supply chains, expedite order processing!

WMS System: Precise inventory management, cost-saving!

PSRA Assistant: Smart scheduling for automated production!

PDM Management: Optimize product data for improved performance!

QRM Quality Records: Elevate quality control, continual optimization!

BI Analytics: Data insights for informed decision-making!

RPA Automation: Streamline workflows, unleash manpower!

Irrespective of your factory's scale, our solutions deliver tangible benefits, aiding you in achieving more efficient and intelligent production processes.

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. This model combined the functions of turning and milling and can provide customers with more working conditions.

2. Optional C-axis for arbitrary angle spindle positioning and contour control

3. Optional Y-axis live tooling device and end live tooling device can be used for inner and outer diameter turning and milling.

4. Optional:Y-axis side milling device (4-shaft, ER-20), and the distance between each shaft reaches 55mm.

SHENG FENG TECHNOLOGY CO.,LTD

Product Description :

Cross roller bearings consist of inner rings, outer rings, spacer retainers and cylindrical rollers cross arranged on the V-shaped 90° groove between the inner and outer rings. This structure can withstand radial, axial and moment loads in all directions because the rollers'line contact with raceway surfaces achieve a large load-bearing area despite the minimum dimensions. Therefore these bearings are widely used on the rotating parts of industrial robots, machine tools, precision rotary tables, measuring instruments and IC manufacturing machines.

Cross Roller Bearing Features:

High rigidity

Large load capacity

High rotation accuracy

Compactness

Easy to install and handle

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON is an experienced measuring technology manufacturer for the industry and the market leader in fill level measurement in the field of dispensing technology. Capacitive CAPTRON probes accurately and reliable measure the fill levels of liquids, bulky goods, pastes, adhesives and chemically aggressive materials.

With the CAPselect system for level sensors, you are able to freely configure the probe of your choice depending on the application, container type and sensor properties. CAPTRON produces these with millimetre accuracy to ensure full flexibility.

There are two systems to choose from: Compact probes, in which the electronics and probe form a single unit. Probes with external amplifiers that are suitable for applications with high temperatures and pressures.

Thanks to their wear-free electronics combined with high-quality material such as stainless steel, Teflon and Peek, CAPTRON level sensors are reliable, robust and long-lasting.

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

FEATURES :

• 10 Display Easy - to - View LCD Screen.

• Connectors for 4 Current Sensing Clamps.

• 1P2W, 1P3W, 3P3W2M, 3P3W3M & 3P4W Power Measurement.

• True RMS Sensing.

• Power KW, KVAR, KVA, PF,θ,Hz, &

Energy KWh, KVARh & KVAh Measurement.

• Phase sequency indicator function.

• Backlight display function.

• Manual Data Memory and Read (50 sets).

• Data Logging

• USB Optical Interface with three phase voltage /

current Waveform display and Harmonic analysis.

• Easy - to - use Push - Button Operation.

• Light Weight, Portable Design.