Theme

Digital Transformation

Green Transformation

JEFFER MACHINERY CO., LTD.

Product Description :

JF-1600 Automatic Knife Grinder (wheel moveable version) is for grinding long and straight knives. For example, paper cutting knife, single side cutting knife, veneer cutting knife, planer knife and etc. Standard machine is for grinding straight knife length up to 1600mm. We could also extend this machine to grind straight knife length up to 2100mm. With user-friendly electronic control, it lets the operator as using it as enjoying it.

JF-1600 Feature :

1. Can obtain good, sharp knives by using a fine grinding wheel after a rough one.

2. Force cooling system gets knives neither heated, transfigured nor annealed.

3. Grinding wheel back-front movement with ball screw sets which obtain accurate and best result.

4. With magnetic chuck parallelism ± 0.02mm and high accuracy.

5. Equipped with variable speed motor for fine grinding wheel to grind high speed steel knives and carbide knives.

6. Splash guard and coolant tank are stainless steel.

7. Grinding capacity (LxWxT):1600x153x19mm

8. Fixed cutter by Magnetic Chuck.

GUANDA INTERNATIONAL MACHINERY CO., LTD

Product Description :

Specifically designed for steel beam / structural steel processing. STD 105 equips with 3 spindles working simultaneously. Each spindle works with a BT-40 ATC, which increases the working efficiency and flexibility.

We apply MQL (minimum quantity lubrication) not only to improve the working environment but also to reduce the operation cost.

We provide various automation solutions to meet your needs.

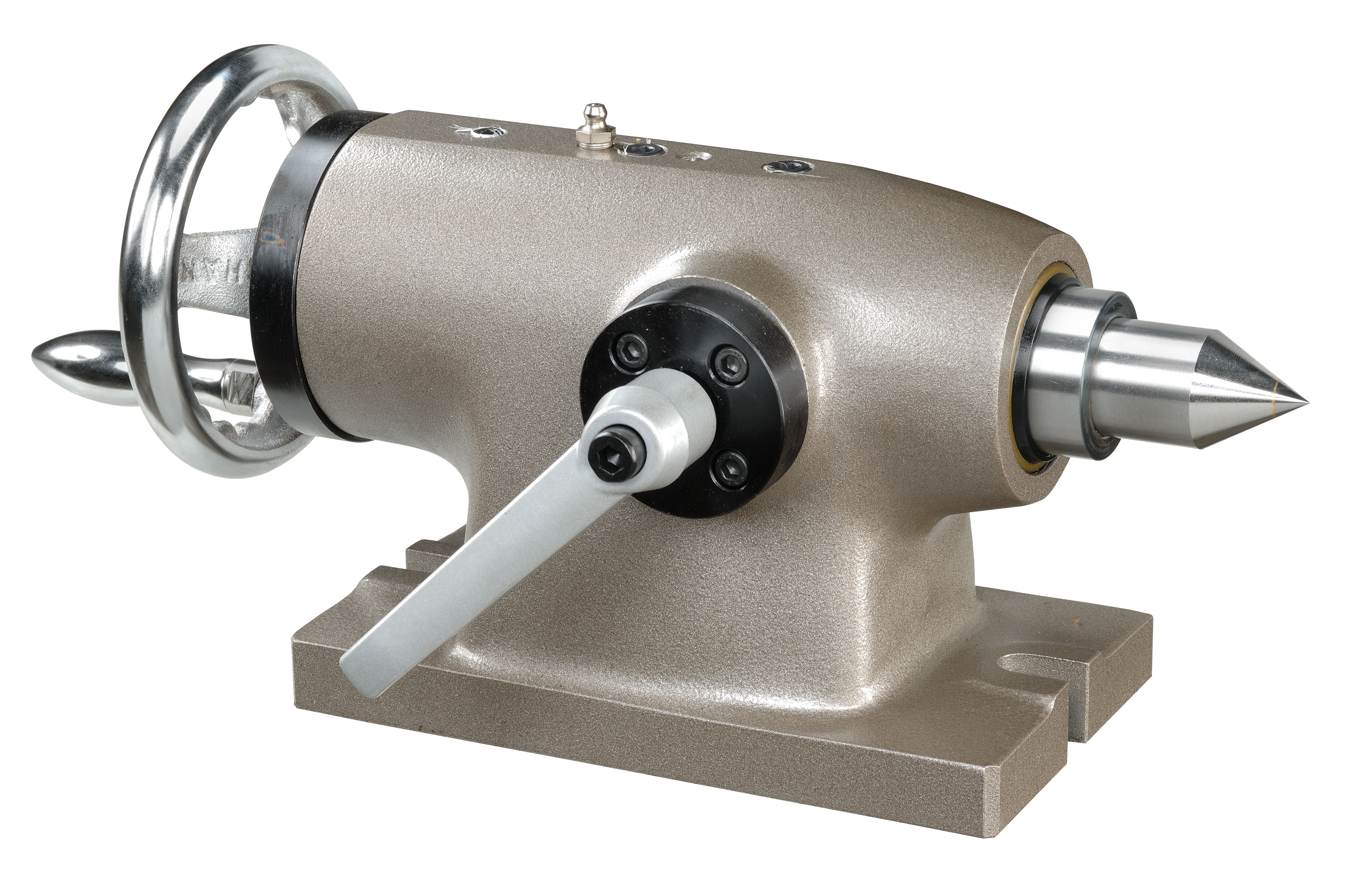

HSU PEN INTERNATIONAL PRECISION MACHINERY CO., LTD.

Product Description :

*The tailstock is ruggedly constructed for high rigidity.

*The mini type 125S is suitable for small type machine tools for light cutting applications.

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

Strong casting and the perfect boxway stucture provides excellent cutting capacity for TTB-20MW Series. Sub-spinfle with milling function and Y-axis can satisfy customers' miltiple needs.

-The one cast base incorporates FEM analysis to achieve its optimal ribbing and structure to further enhance machine rigidity and stability.

-The 30 degree slant bed design has low center of gravity for easier swarf management and better erogonomic design. The TTB-20MW Series also offer optional rear type chip conveyor.

-To make sure the usage life of Y-axis ballscrew will get longer, there are three bearing on Y-axis ballscrew to enhance the support for pressure from top.

-The TTB-20MW Series can achieve maximum 20m/min for X axis and 25m/min for X axis. And the servo motors adopt absolute encoders for faster and more reliable positioning.

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

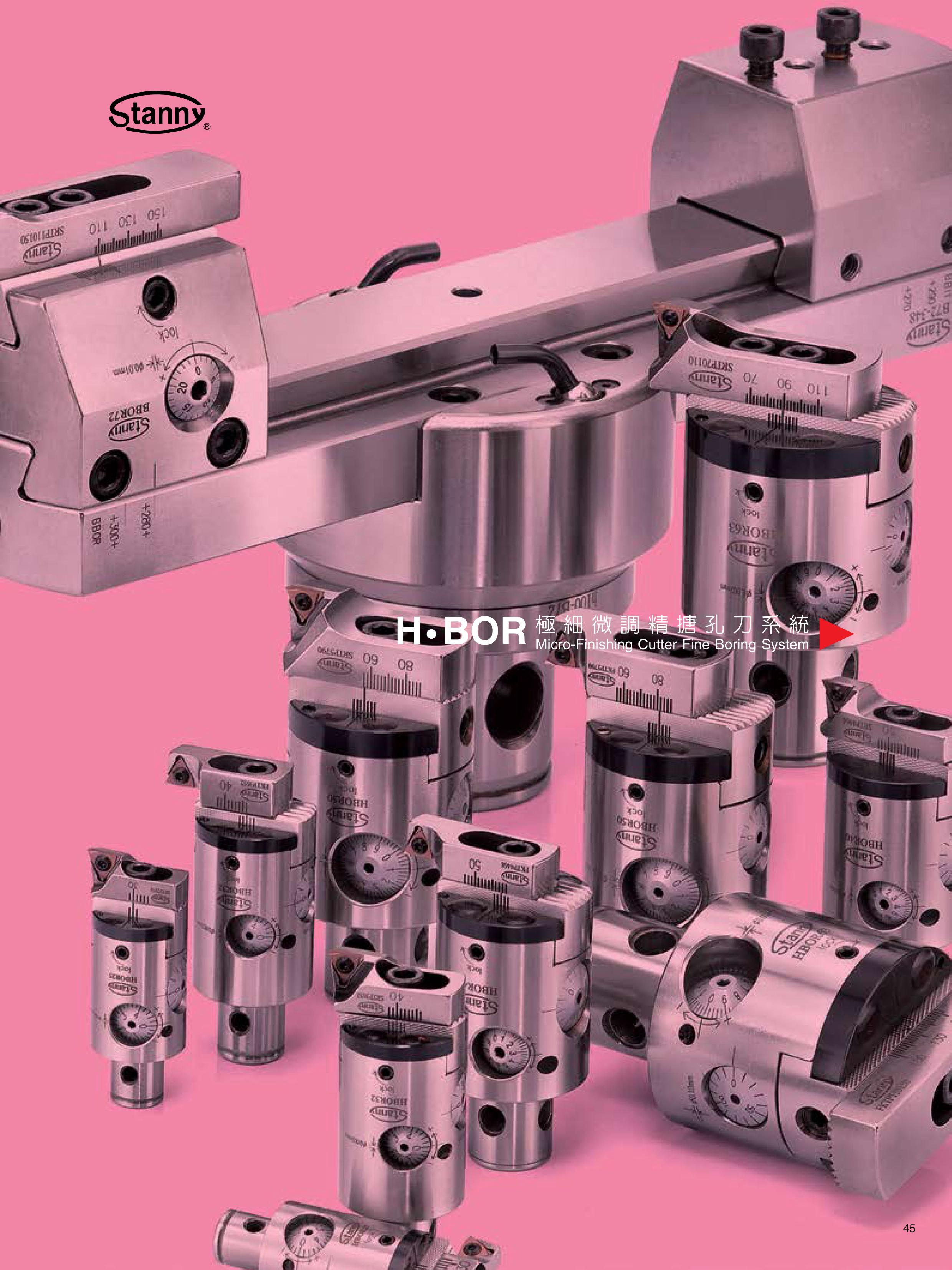

STANNY MACHINE TOOLS CO., LTD.

Product Description :

HBOR Micro-Finishing Cutter Fine Boring Sysetm, the boring range Ø2~Ø230, have SRTP,SRTC,SRCC,SR9C,FKTP,FKCC and FK9C-type cutting insert holder.

HIWIN TECHNOLOGIES CORPORATION

Product Description :

【ESG Sustainable Goal for Motion Control Components】

According to TrendForce research, the green factories will boost the global smart manufacturing market, which will reach $620 billion by 2026. As the concept of ESG sustainability has set off a wave of enthusiasm around the world, HIWIN linear motion components have also continued to focus on intelligent energy-saving innovation, providing simple, safe and modular designs to help customers upgrade from the inside out and embrace the trend of ESG energy saving!

The world’s first Intelligent 4.0 Ballscrew i4.0BS®, together with Intelligent 4.0 Guideway i4.0GW® and Intelligent Single-Axis Robot provide users to monitor health conditions of multiple machines and allow users to plan the production and pre-schedule the maintenance. The function of improving productivity and reducing carbon emission is also in line with the ESG sustainable goal.

-i4.0BS® multi-function sensors design with algorithm, effectively monitor the status of the Ballscrew. The users can monitor machines' conditions anytime.

-i4.0GW® sensor can be mounted on the block according to customers' demand. The system is fully compatible with i4.0BS®.

-The intelligent single-axis robot iSR has a modular design to meet the users' needs in various fields.

MING YANG MACHINERY CO., LTD.

Product Description :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.Cross feed and vertical feed are driven by servo motors.

2.Horizontal spindle head,vertical spindle head(optional).

3.Double column construction and extra large diameter of rotary table.

4.The rotary table running is driven by a powerful motor and controlled by frequency inverter.

5.Two axes are servo controlled.

KING NICE TECH.CO., LTD.

Product Description :

To solve the cutting of iron filings,aluminum powder,fine sediment...and other long-time deposition in the CNC water tank troubled.

Take the air pressure drive way, to avoid pubilc security problems.

Widely used in metal cutting, aluminum processing,grinding problems,engineering plastics Patented technology-easy to deal with oily and water-soluble cutting fluid.

patented technology - special dehydration drying method, can clean CNC water tank.

processing liquid, sludge can also be a short time to cleat.

the maximun filter accuracy can to 1 um.

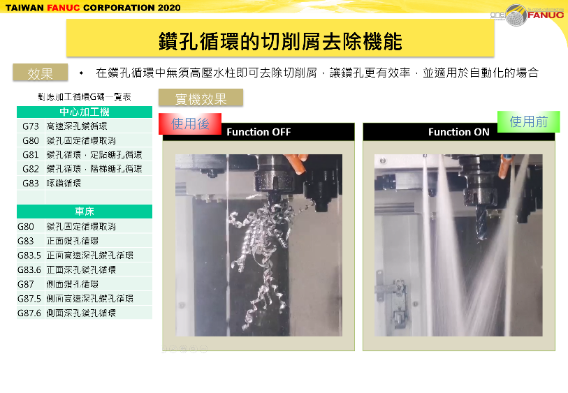

TAIWAN FANUC CORPORATION

Product Description :

Machine center chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.